In the quest for sustainable construction, a groundbreaking study led by G. Murali from the Centre for Promotion of Research at Graphic Era University in India is making waves. Published in the journal *Results in Engineering* (translated from Russian as “Results in Engineering”), the research delves into the promising world of 3D-printed geopolymer concrete (3DPGC), a low-carbon alternative to traditional concrete that could revolutionize the energy sector and beyond.

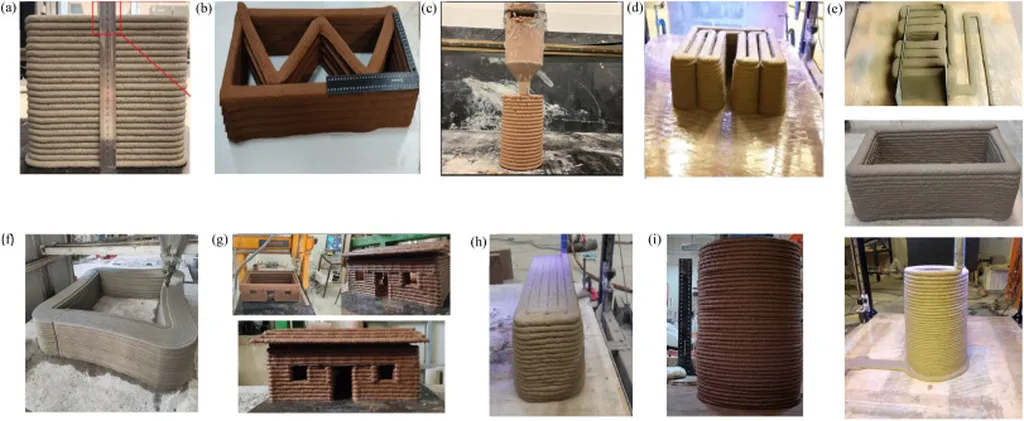

The study highlights the critical role of waste-derived precursors in optimizing the rheology, buildability, and mechanical performance of 3DPGC. “Printability and structural integrity are highly sensitive to mix composition, rheological tuning, and particle packing,” explains Murali. This sensitivity means that the right blend of materials can significantly enhance the performance of 3DPGC, making it a viable option for large-scale construction projects.

One of the key findings is the impact of supplementary materials like slag, ordinary Portland cement, or waste glass powder on the yield stress, viscosity, and interlayer bonding of 3DPGC. These materials can modulate the properties of the concrete, directly influencing its shape retention and adhesion. “Moderate reactive filler content promotes geopolymerisation and microstructural densification, whereas excessive inert additions reduce performance,” notes Murali. This balance is crucial for achieving the desired mechanical properties and structural integrity.

The mechanical behavior of 3DPGC also exhibits pronounced anisotropy due to interlayer weaknesses, with strength predominantly arising from amorphous gel formation. This understanding is vital for designing structures that can withstand the rigors of construction and usage.

The commercial implications of this research are substantial. As the energy sector increasingly seeks sustainable and efficient construction methods, 3DPGC offers a promising solution. Its low-carbon footprint and material efficiency make it an attractive option for building energy-efficient structures, reducing the environmental impact of construction projects.

Moreover, the use of waste materials in 3DPGC aligns with the growing trend of circular economy practices, where waste is repurposed to create valuable products. This not only reduces waste but also lowers the cost of raw materials, making 3DPGC a cost-effective solution for the energy sector.

The research also underscores the importance of sustainability metrics in evaluating the performance of 3DPGC. By considering the environmental impact of construction materials and methods, the energy sector can make informed decisions that balance performance, cost, and sustainability.

As the construction industry continues to evolve, the insights from this study could shape future developments in the field. By optimizing the mix composition and rheological properties of 3DPGC, researchers and engineers can develop innovative construction methods that are both sustainable and efficient. This could lead to the creation of new building designs and structures that are not only environmentally friendly but also cost-effective and durable.

In conclusion, the research led by G. Murali offers a compelling vision of the future of construction. By leveraging the potential of 3DPGC, the energy sector can achieve its sustainability goals while also driving innovation and efficiency in construction practices. As the industry continues to explore new materials and methods, the insights from this study will undoubtedly play a crucial role in shaping the future of sustainable construction.