In the quest for sustainable construction materials, a team of researchers from SRM Institute of Science and Technology in India has made a significant stride. Led by Dhanasingh Sivalinga Vijayan, the team has explored the potential of Ferrock, a material synthesized from industrial waste, as a partial replacement for cement in concrete. Their findings, published in the journal Scientific Reports, offer a promising avenue for reducing the carbon footprint of the construction industry.

The study investigated Ferrock at various dosage levels, from 10% to 50% by weight of cement. The results were compelling. “We found that a 10% replacement of cement with Ferrock produced the most favourable mechanical performance,” Vijayan explained. This optimal mix not only enhanced the strength and durability of the concrete but also significantly reduced chloride permeability and improved thermal stability.

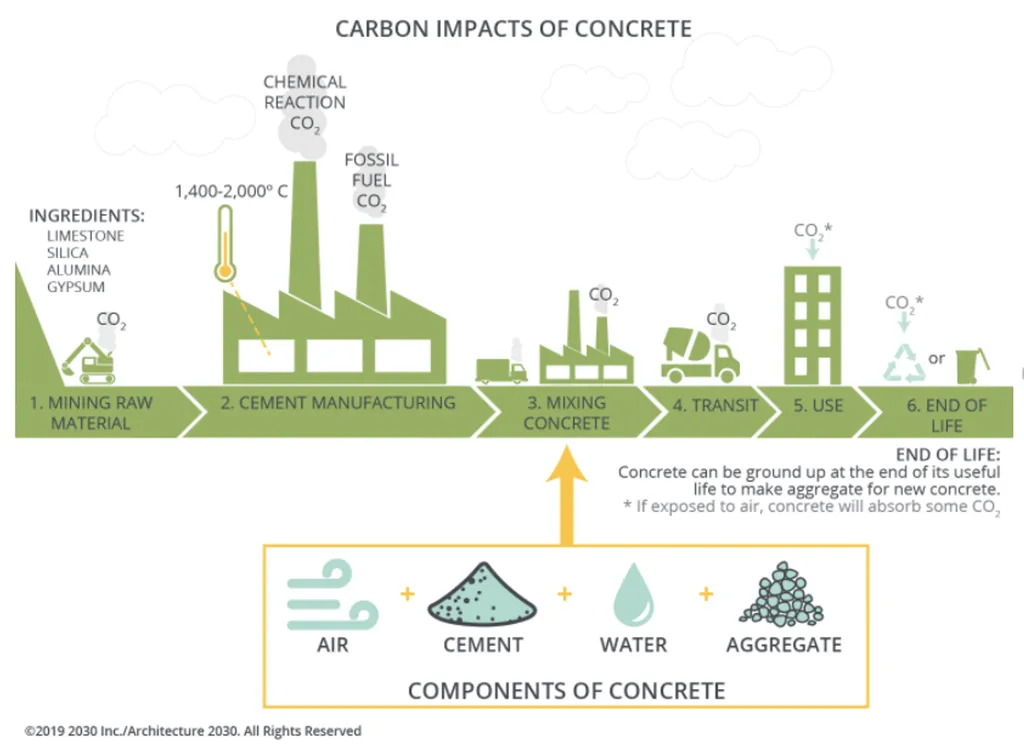

The environmental benefits are equally noteworthy. The team conducted a cradle-to-site sustainability assessment, which revealed that incorporating Ferrock reduces embodied energy, global warming potential, and overall material use costs. This is a significant step forward in the fight against climate change, as the construction industry is a major contributor to global carbon emissions.

The commercial implications for the energy sector are substantial. As the world shifts towards sustainable energy solutions, the demand for eco-friendly construction materials is on the rise. Ferrock-infused concrete could become a key player in this market, offering a cost-effective and environmentally friendly alternative to traditional concrete.

The study also employed advanced techniques such as Scanning Electron Microscopy and Fourier Transform Infrared Spectroscopy to examine the microstructural characteristics of the concrete mixes. Response Surface Methodology was used to optimize the dosages of cement, Ferrock, and oxalic acid, leading to the development of a predictive strength model. This innovative approach not only enhances our understanding of Ferrock-infused concrete but also paves the way for future research and development in the field.

As the construction industry continues to evolve, the integration of sustainable materials like Ferrock could reshape the landscape of building practices. The findings of this study offer a glimpse into a future where eco-friendly materials are not just an option but a standard. “Our research confirms that a 10% Ferrock addition offers an optimal balance of mechanical performance, durability, and environmental benefits,” Vijayan stated. This balance is crucial for the widespread adoption of sustainable construction materials, as it addresses both the practical and environmental concerns of the industry.

In conclusion, the study by Vijayan and his team represents a significant advancement in the field of sustainable construction. By demonstrating the potential of Ferrock as a partial replacement for cement, they have opened up new possibilities for reducing the carbon footprint of the construction industry. As the world continues to grapple with the challenges of climate change, such innovations are not just welcome but essential. The journey towards sustainable construction is ongoing, and studies like this one are guiding the way.