In the ever-evolving world of construction materials, predicting and optimizing the compressive strength of cement has long been a complex puzzle. A recent study published in the journal *Scientific Reports* (known in English as “Nature Scientific Reports”) offers a groundbreaking approach that could revolutionize the way we develop and utilize cementitious materials. Led by Rawa Saman Maaroof from the College of Commerce at the University of Sulaimani, this research integrates advanced computational techniques to enhance predictive modeling and optimization of cement mixtures.

The study addresses a fundamental challenge in the construction industry: the intricate and nonlinear interactions of chemical composition, curing time, and processing conditions that affect the compressive strength of cement. Traditional methods often fall short in capturing these complexities, leading to suboptimal material performance and increased costs. Maaroof and her team tackled this issue by combining Response Surface Methodology (RSM) with a Genetic Algorithm (GA), creating a hybrid framework that significantly improves predictive accuracy and optimization outcomes.

Response Surface Methodology is a statistical technique used to model and analyze problems in which a response of interest is influenced by several variables. In this study, RSM was employed to construct polynomial models that capture the relationships between eight oxide compositions and compressive strength at different curing periods—2, 7, and 28 days. The Genetic Algorithm, inspired by the process of natural selection, was then used to explore the high-dimensional solution space and identify optimal compositions.

“Our approach leverages the strengths of both RSM and GA,” explains Maaroof. “RSM provides a robust framework for modeling the complex interactions between variables, while GA efficiently navigates the solution space to find optimal compositions.”

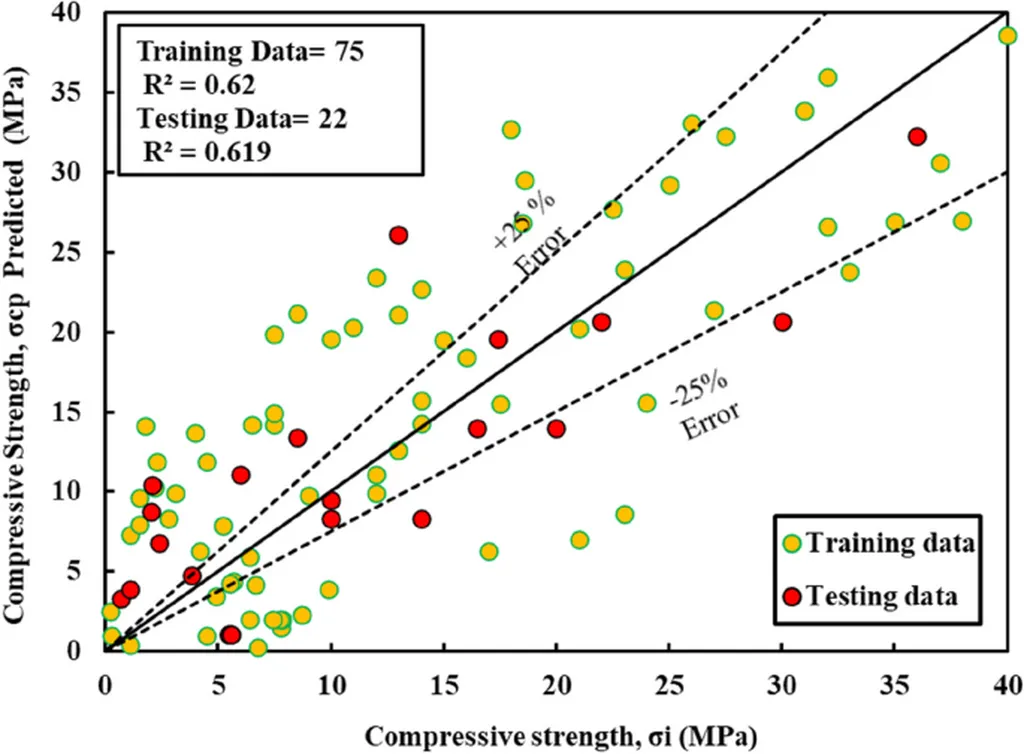

The results of the study are impressive. The full Quadratic model, one of the polynomial models constructed using RSM, consistently outperformed other models, achieving the lowest Root Mean Square Error (RMSE) and highest R-squared (R²) values across all curing periods. When combined with GA optimization, the performance improved even further. Maximum predicted compressive strengths increased by 83% at 2 days, 48% at 7 days, and 43% at 28 days compared to RSM-only predictions.

These findings have significant implications for the construction industry. By improving the accuracy of predictive models and optimizing cement mixtures, the hybrid GA + RSM approach can lead to the development of eco-efficient and high-strength cementitious materials. This not only enhances the durability and performance of construction projects but also contributes to sustainability efforts by reducing material waste and energy consumption.

The study’s lead author, Rawa Saman Maaroof, highlights the potential impact of this research: “This framework offers a promising tool for developing innovative and sustainable construction materials. It can help us create cement mixtures that are not only stronger but also more environmentally friendly.”

As the construction industry continues to evolve, the integration of advanced computational techniques like those used in this study will play a crucial role in shaping the future of building materials. The hybrid GA + RSM approach demonstrated in this research could pave the way for more efficient, cost-effective, and sustainable construction practices, ultimately benefiting the energy sector and beyond.

With the publication of this study in *Scientific Reports*, the construction industry has a new tool at its disposal to tackle the complexities of cement optimization. As Maaroof and her team continue to refine and expand their approach, the potential for innovation in sustainable construction materials grows ever more promising.