In the heart of Iraq, researchers are turning waste into wonder, transforming discarded materials into sustainable building solutions that could reshape the construction industry. Saad Abd AL Jaleel Fathi, a researcher from the Building and Construction Techniques Engineering department at the Northern Technical University, has published a groundbreaking study in the Misan Journal of Engineering Sciences (translated from Arabic as “Journal of Engineering Sciences”) that could revolutionize the way we think about concrete and waste management.

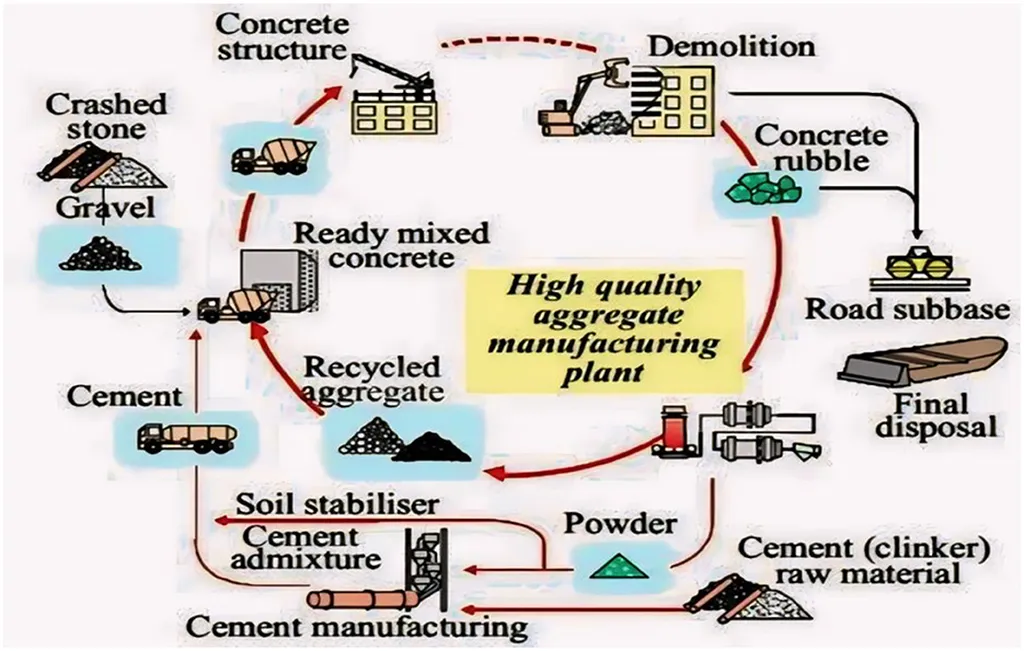

Fathi’s research focuses on two often-overlooked waste materials: wood ash (WA) from fish grills and restaurants, and crushed clay blocks (CCB) from construction and demolition waste. By incorporating these materials into concrete mixtures, Fathi aims to mitigate the environmental impacts of cement production and reduce the burden on landfills.

The study found that replacing 10% to 20% of cement with wood ash can slightly improve the strength and durability properties of concrete. “The ideal replacement ratio is around 10% to 20%,” Fathi explains. “This is where we see the highest compressive, tensile, and flexural strength.”

But Fathi didn’t stop there. He also explored the potential of crushed clay blocks as a replacement for normal coarse aggregate in concrete. The results were promising, with the optimal mixture achieving impressive strength properties. “The highest compressive, tensile, and flexural strengths were achieved at 10% WA substitution with 50% CCB,” Fathi reveals.

The implications for the energy sector are significant. Cement production is a major contributor to global carbon emissions, accounting for around 8% of the world’s CO2 output. By replacing a portion of cement with wood ash, we could significantly reduce these emissions. Moreover, by using crushed clay blocks as a substitute for normal coarse aggregate, we can divert construction and demolition waste from landfills, further reducing the environmental impact of the construction industry.

Fathi’s research also has commercial potential. As the demand for sustainable building materials grows, so too does the market for innovative solutions like those proposed in this study. Construction companies that adopt these practices could gain a competitive edge, appealing to environmentally conscious clients and investors.

The study also highlights the importance of long-term thinking in the construction industry. While the strength properties of the concrete mixtures decreased as the WA and CCB substitution ratios increased, they improved over time due to pozzolanic effects. This suggests that the benefits of these materials may not be immediately apparent but could pay off in the long run.

Fathi’s research is a testament to the power of innovation and the potential of waste materials. As we grapple with the challenges of climate change and resource depletion, studies like this offer a glimmer of hope, a reminder that the solutions to our problems may be hiding in plain sight.

In the words of Fathi, “This research aims to use WA in the manufacture of non-load-bearing insulating building units.” But the potential applications of this work extend far beyond that. By turning waste into wonder, Fathi is paving the way for a more sustainable, efficient, and innovative construction industry. The future of building is here, and it’s made from waste.