In the quest for sustainable construction materials, a team of researchers led by Pimpet Sratong-on from the Composite Materials and Lightweight Structures Laboratory at the Thai-Nichi Institute of Technology in Bangkok has made a significant breakthrough. Their study, published in *Composites Part C: Open Access* (translated as *Composites Part C: Open Access*), explores the potential of mycelium biocomposites (MBCs) derived from waste materials like spent coffee grounds, rice husks, and recycled paper for non-structural construction applications.

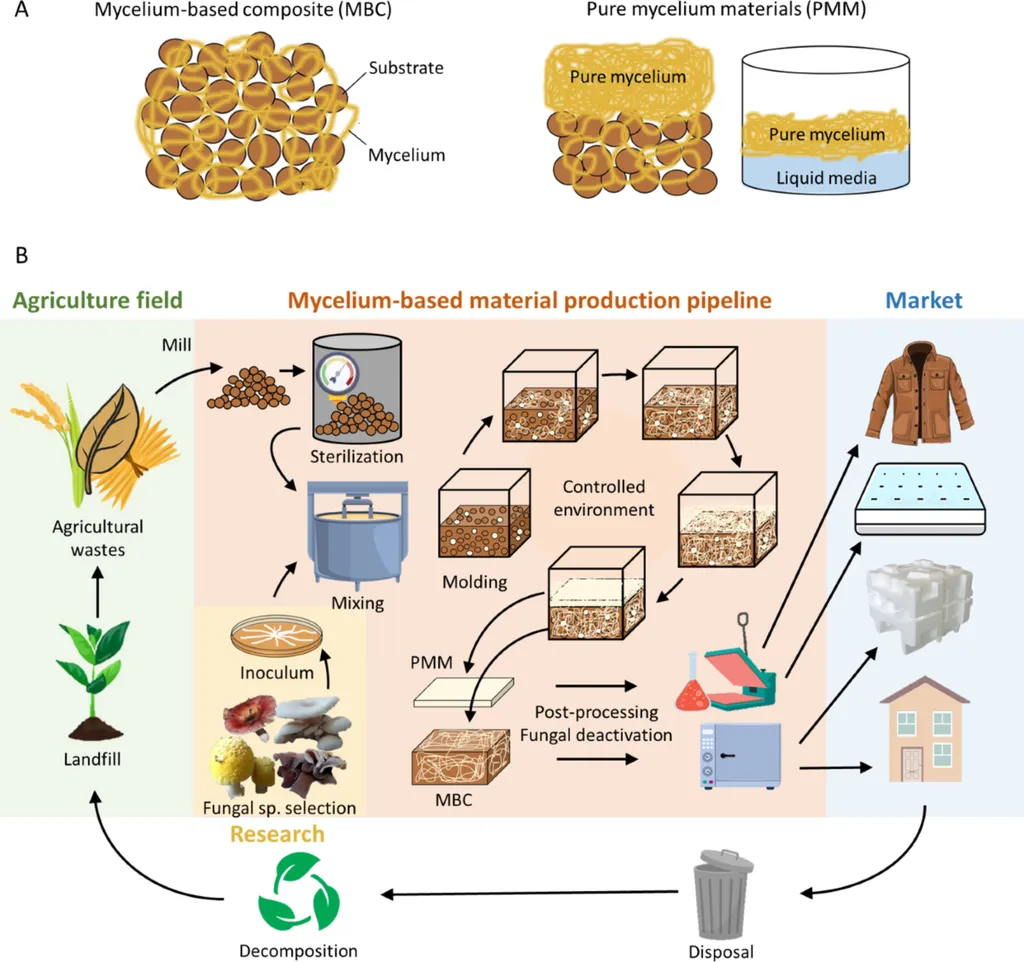

The research delves into the influence of substrate morphology on the properties of MBCs, focusing on their mechanical strength, water absorption, and fire resistance. By experimenting with different compositions—fibrous recycled paper (RP) alone and a mix of spent coffee grounds (SCG) with rice husks (RH)—the team discovered that the structure of the substrate plays a critical role in the performance of the final material.

“Substrate morphology critically governs MBC performance,” Sratong-on explained. The team found that MBCs made from recycled paper achieved the highest compressive strength and excellent fire resistance due to the dense mycelial entanglement and the formation of a protective char layer. This makes MBC/RP a promising candidate for non-structural construction materials, such as road guideposts.

In contrast, MBCs made from a mix of spent coffee grounds and rice husks exhibited lower strength and fire resistance but showed superior stiffness and lower water uptake. “MBC/SCG-RH groups are better suited for biodegradable packaging,” Sratong-on noted, highlighting the versatility of these materials for different applications.

The practical feasibility of their findings was validated by successfully fabricating a 1:4 scale MBC/RP road guidepost prototype. This prototype demonstrated the potential of MBCs to maintain structural integrity in dry environments for over three months, despite being susceptible to high moisture.

The implications of this research are far-reaching. As the construction industry seeks to reduce its environmental impact, the development of sustainable, zero-waste materials like MBCs could revolutionize the way we build. “These findings confirm the potential of tailoring waste resources to meet mechanical, fire performance, and degradability requirements for non-load-bearing outdoor applications,” Sratong-on said.

This study not only opens new avenues for utilizing agricultural and industrial waste but also paves the way for innovative solutions in the construction and packaging industries. As the world moves towards a more sustainable future, the insights gained from this research could shape the development of next-generation materials that are both eco-friendly and functional.