In the quest for sustainable construction practices, researchers have made a significant stride in enhancing the predictability of recycled aggregate concrete (RAC), a material that is increasingly vital in reducing environmental pollution and promoting circular economy principles. A recent study, published in the journal “Advances in Engineering and Intelligence Systems” (which translates to “Fortschritte in Ingenieurwesen und Intelligente Systeme”), introduces a novel approach that combines machine learning and optimization techniques to accurately predict the elastic modulus of RAC. This breakthrough could have profound implications for the construction and energy sectors, where sustainable materials are increasingly in demand.

At the helm of this research is Auguste Albrecht, a civil engineering expert from the University of Siegen in Germany. Albrecht and his team recognized the challenges posed by the variability in RAC’s material composition, which has historically made it difficult to predict its elastic modulus using traditional empirical formulas. “The inconsistency in RAC’s properties has been a major hurdle in its widespread adoption,” Albrecht explains. “Our goal was to develop a more reliable method to predict its behavior, thereby facilitating its use in sustainable construction projects.”

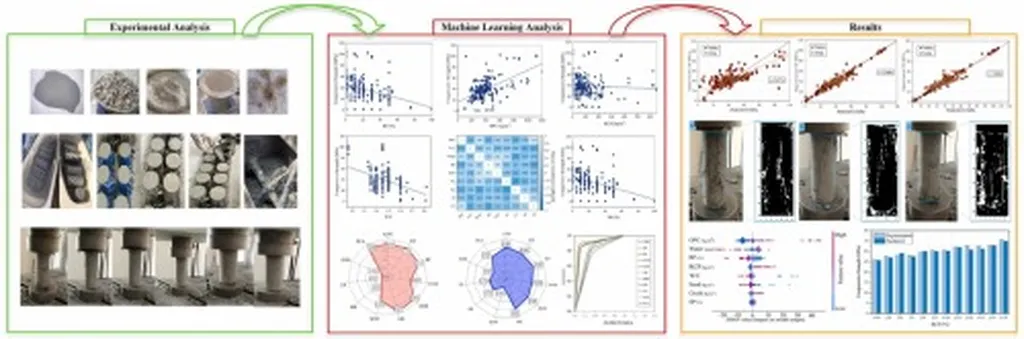

To tackle this issue, the researchers turned to advanced machine learning models: Adaptive Boosting Regression (ADAR) and Stacking Regression (Stacking). These models are known for their robust learning capabilities, which allow them to handle complex datasets with high variability. However, the team didn’t stop there. They further enhanced the predictive performance of these models by integrating them with the Electrostatic Discharge Algorithm (EDA), a metaheuristic optimization technique. This integration resulted in two hybrid frameworks: ADED (ADAR + EDA) and STED (Stacking + EDA).

The results were impressive. The ADED model achieved the highest accuracy, outperforming other models in predicting the elastic modulus of RAC. The STED model also performed exceptionally well, with an R² value of 0.982, indicating a very high degree of correlation between the predicted and actual values. “The accuracy of these models is a game-changer,” says Albrecht. “It provides engineers and architects with the confidence they need to incorporate RAC into their designs, knowing that its structural properties can be reliably predicted.”

The implications of this research extend beyond the construction industry. In the energy sector, where sustainability is a key focus, the ability to accurately predict the properties of recycled materials can lead to more efficient and environmentally friendly building practices. For instance, the use of RAC in energy-efficient buildings can reduce the carbon footprint of construction projects, aligning with global efforts to combat climate change.

Moreover, the success of this study highlights the potential of machine learning and optimization techniques in addressing complex challenges in materials science. As Auguste Albrecht notes, “This research opens up new avenues for exploring the use of advanced computational methods in predicting material properties. It’s an exciting time for the field, and we’re just scratching the surface of what’s possible.”

In conclusion, the study by Auguste Albrecht and his team represents a significant step forward in the quest for sustainable construction materials. By leveraging the power of machine learning and optimization, they have developed a reliable method for predicting the elastic modulus of RAC, paving the way for its broader adoption in the construction and energy sectors. As the world continues to grapple with the challenges of environmental sustainability, such innovations will be crucial in shaping a greener future.