In the quest for sustainable construction materials, researchers have turned their attention to two industrial by-products: steel slag (SS) and granulated blast furnace slag (GBFS). A comprehensive review published in the journal *Case Studies in Construction Materials* (translated as *Case Studies in Construction Materials*) sheds light on the activation methods and performance of these materials, offering promising insights for the construction and energy sectors.

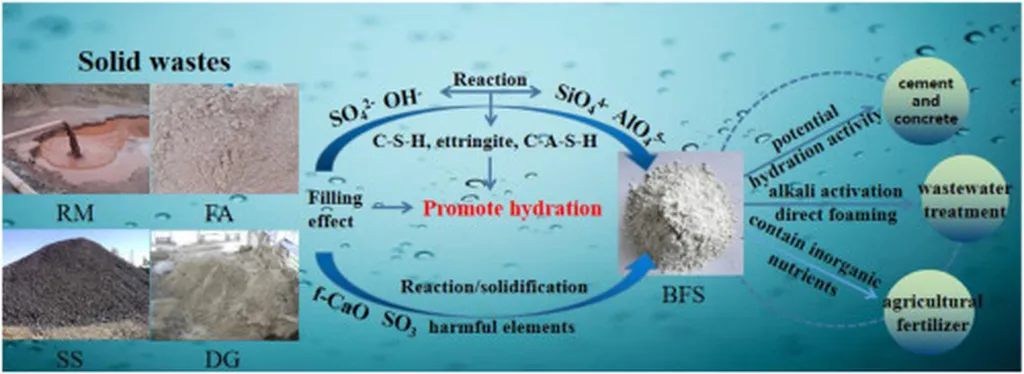

Steel slag and granulated blast furnace slag are primary solid by-products of the iron and steel industry. Their efficient use is crucial for reducing the carbon footprint of construction materials and managing solid waste disposal. However, challenges such as the low reactivity and poor volume stability of SS, along with the dependency of GBFS on activators and the scarcity of high-quality slag resources, have hindered their widespread application.

Yongfeng Wan, a researcher from the College of Materials Science and Engineering at Xi’an University of Architecture and Technology, led a systematic review of the primary activation strategies for SS and GBFS. The study focuses on mechanical grinding activation, alkali activation, sulfate/chloride activation, carbonation treatment, and emerging techniques involving acid/acid phosphates, organic/biomass additives, microorganism, and physical field assistance.

“An optimal synergistic hydration effect is achieved within an SS/GBFS mass ratio of 2:3–3:2,” Wan explains. Among the chemical methods, alkali activation shows the most pronounced effect by inducing a dense C–(A)–S–H gel network. In contrast, mechanical grinding and sulfate/chloride activation offer a more cost-effective approach by enhancing mineral dissolution and regulating the precipitation of ettringite, monosulfoaluminate, and Friedel’s salt.

The review also highlights emerging sustainable approaches that leverage industrial by-products like gypsum and alkaline residues, trace organic alkanolamines, or biomass ash. These methods demonstrate superior potential for developing eco-friendly binders, which could significantly impact the energy sector by reducing the carbon footprint of construction materials.

The research evaluates the workability, compressive strength, durability, and environmental performance of SS–GBFS binders. “This review provides a theoretical foundation and technical reference for the design and industrial application of high-performance, low-carbon SS–GBFS cementitious materials,” Wan states.

The findings suggest that the activation methods and performance of SS–GBFS binders could shape future developments in the construction and energy sectors. By optimizing the use of these industrial by-products, researchers and industry professionals can work towards more sustainable and efficient construction practices.

As the demand for low-carbon materials grows, the insights from this review could pave the way for innovative solutions that reduce waste and lower the environmental impact of construction projects. The study not only offers a comprehensive analysis of current activation methods but also points towards future research directions, making it a valuable resource for professionals in the field.