In the heart of Ethiopia, a groundbreaking development is taking shape, one that could redefine the construction industry’s approach to sustainable materials. Addisu Negash Ali, a researcher from the Department of Machining, has spearheaded a study that promises to enhance the mechanical properties of agrostone panels, commonly used for interior walls. The research, published in the *Journal of Engineering*, explores the integration of locally abundant rice husk and bamboo fiber into these panels, potentially unlocking new avenues for sustainable construction.

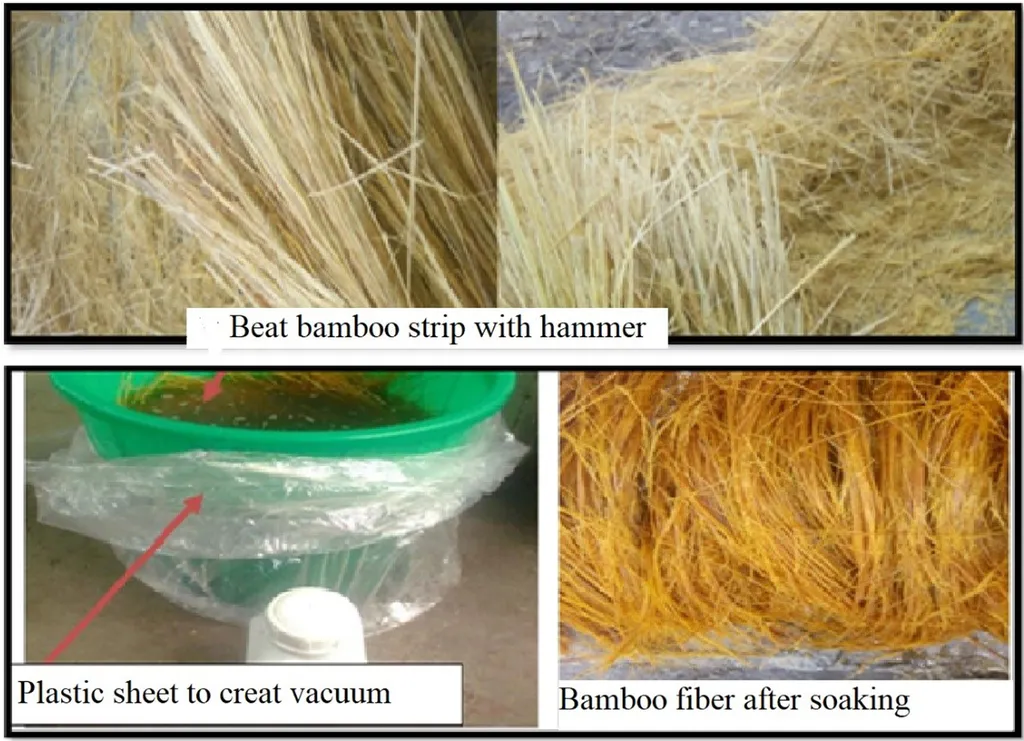

Agrostone panels, typically made from agricultural waste like bagasse and reinforced with glass fiber, are already a staple in eco-friendly construction. However, Ali’s work takes this a step further by introducing rice husk and bamboo fiber into the mix. “We aimed to investigate the effect of these additives,” Ali explains, “to optimize the mechanical properties of these panels without altering the matrix materials.”

The study employed a central composite design (CCD) to determine the initial optimized parameters for the variables—rice husk and bamboo fiber—at three different levels. The data collected was then analyzed using regression analysis and ANOVA, feeding into response surface methodology (RSM) to fine-tune the proportions of these additives. The goal was to maximize the mechanical properties of the panels, including tensile, compressive, flexural, and impact strength.

The results were promising. The optimized proportions of 3.091% rice husk and 1.358% bamboo fiber yielded impressive mechanical properties. “The highest tensile, compressive, flexural, and impact strength values were 64.92 MPa, 75.534 MPa, 65.168 MPa, and 63.485 J, respectively,” Ali reveals. These findings were validated through experimental data, showing a close match with the predicted values.

The implications of this research are significant for the construction industry, particularly in regions where rice husk and bamboo fiber are abundantly available. By enhancing the mechanical properties of agrostone panels, this study could lead to more durable and sustainable building materials. “This could revolutionize the way we think about construction materials,” Ali suggests, “especially in terms of sustainability and local resource utilization.”

Moreover, the energy sector could benefit from this innovation. As the demand for energy-efficient buildings grows, materials that offer both strength and sustainability become increasingly valuable. The optimized agrostone panels could contribute to the development of energy-efficient structures, reducing the overall energy consumption of buildings.

This research not only highlights the potential of local agricultural waste as a valuable resource but also underscores the importance of innovative approaches in sustainable construction. As the world grapples with the challenges of climate change and resource depletion, studies like Ali’s offer a glimmer of hope, demonstrating that sustainable solutions are within reach. The findings, published in the *Journal of Engineering*, serve as a testament to the power of research and innovation in driving the construction industry towards a more sustainable future.