In a groundbreaking study published in ‘Science and Technology of Advanced Materials’, researchers have harnessed machine learning to predict the mechanical properties of magnesium-based rare earth alloys, a development that could significantly impact the construction sector. As the industry increasingly seeks lightweight materials to enhance efficiency and reduce costs, this innovative approach could pave the way for stronger, more durable building materials.

Sandeep Jain, the lead author from the School of Advanced Materials Science and Engineering at Sungkyunkwan University in South Korea, emphasizes the importance of this research. “By applying machine learning techniques to various thermomechanical processes, we can predict how these alloys will behave under different conditions,” Jain explains. This capability allows engineers and manufacturers to optimize the production of these materials, ensuring they meet specific performance criteria.

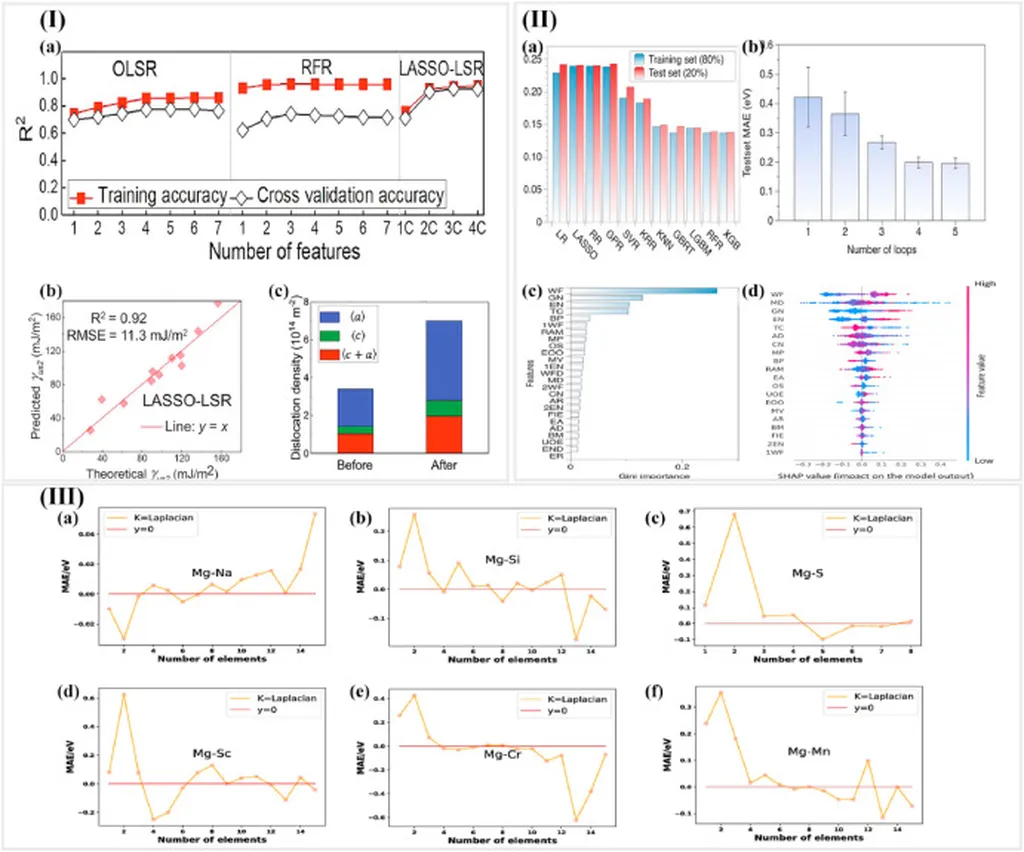

The study explored a range of thermomechanical processes, including solution treatment, homogenization, extrusion, and aging. The researchers evaluated the effectiveness of different machine learning models, ultimately identifying the K-Nearest Neighbors (KNN) model as the most accurate. With an impressive Coefficient of determination (R²) of 0.955, alongside a Mean Absolute Error (MAE) of 3.4% and a Root Mean Square Error (RMSE) of 4.5%, the KNN model stands out as a reliable tool for predicting mechanical behavior.

This advancement is particularly timely as the construction industry faces increasing pressure to adopt lighter materials without compromising strength or durability. The ability to accurately forecast the mechanical properties of these alloys means that construction firms can make informed decisions about material selection, potentially leading to safer and more efficient building practices. Jain notes, “Our findings can help manufacturers tailor the properties of Mg rare earth alloys, ultimately leading to lighter structures that can withstand greater loads.”

As the construction sector continues to evolve, the integration of machine learning into materials science could become a game-changer. The insights gained from this research not only enhance the understanding of magnesium alloys but also open avenues for innovation in lightweight applications. The implications for sustainability and cost-effectiveness in construction are profound, making this study a noteworthy contribution to the field.

For those interested in learning more about this research, additional details can be found through the lead author’s affiliation at School of Advanced Materials Science and Engineering, Sungkyunkwan University.