In the relentless pursuit of innovative solutions for diabetic wound care, a groundbreaking study has emerged from the collaborative efforts of researchers at Nanjing Drum Tower Hospital and Åbo Akademi University. Led by Lu Fan, a specialist in rheumatology and immunology, the team has developed a novel microneedle patch designed to revolutionize the treatment of chronic wounds. This isn’t just another incremental improvement; it’s a leap forward in medical technology that could have far-reaching implications for the healthcare and energy sectors alike.

Imagine a patch so advanced that it can breathe, adapt to the wound environment, and promote healing from within. This is precisely what Fan and his team have achieved. The microneedle patch is a marvel of bioengineering, consisting of a breathable porous supporting substrate and core-shell tips. The outer shell is made of poly(vinyl alcohol) loaded with antimicrobial peptides, while the core is composed of crosslinked Gelma hydrogel encapsulated with exosomes.

The innovation doesn’t stop at the patch’s structure. The PVA shell is crosslinked with a reactive oxygen species (ROS)-responsive linker, which degrades in the inflammatory microenvironment of a wound. This degradation triggers the release of antimicrobial peptides, effectively inhibiting bacterial growth. Meanwhile, the Gelma core continuously releases exosomes, promoting tissue regeneration and regulating the immune response. “The beauty of this design,” Fan explains, “is that it mimics the body’s natural healing processes, providing a sustained and targeted approach to wound care.”

The high porosity of the supporting substrate makes the patch particularly suitable for chronic wounds, which often struggle with poor oxygenation and slow healing. This breathability is a game-changer, as it allows the wound to heal in an environment that closely resembles healthy skin. The patch’s ability to adapt to the wound’s needs and promote healing from within could significantly reduce the time and resources required for diabetic wound management.

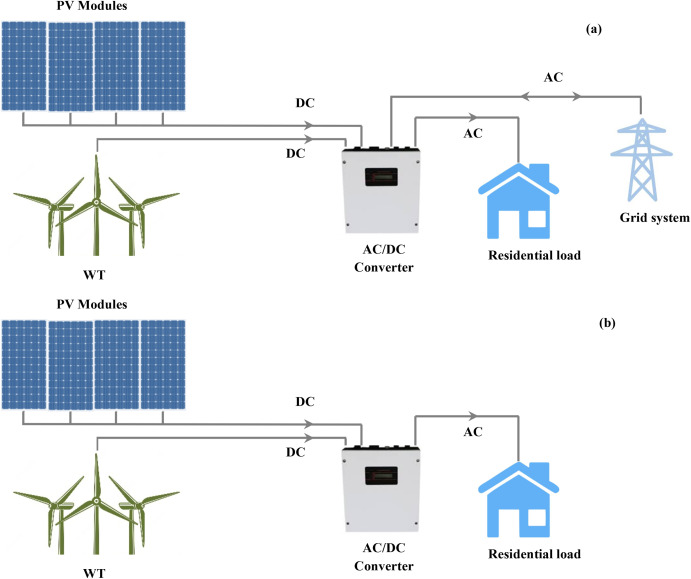

The potential commercial impacts of this research are vast. For the healthcare sector, this patch could lead to a new generation of wound care products that are more effective and efficient. For the energy sector, the principles behind this patch’s design—particularly its breathability and adaptability—could inspire innovations in materials science. Imagine solar panels that can breathe and adapt to their environment, or batteries that can regulate their temperature more effectively. The possibilities are as boundless as they are exciting.

Fan’s work, published in the journal ‘Materials Futures’ (translated from English as ‘Materials of the Future’), is a testament to the power of interdisciplinary collaboration. By bringing together expertise from rheumatology, immunology, and materials science, the team has created a patch that could change the way we think about wound care. As we look to the future, it’s clear that innovations like this will play a crucial role in shaping the next generation of medical and energy technologies. The question is not if these innovations will happen, but when. And with researchers like Lu Fan leading the charge, the answer might be sooner than we think.