In the quest to enhance the performance of materials crucial for the energy sector, a groundbreaking study has emerged from the labs of Babol Noshirvani University of Technology in Iran. Led by Masoomeh Oliaei, a materials engineering expert, the research delves into the intricate world of copper-tungsten composites, revealing how subtle adjustments in processing can yield significant improvements in mechanical and electrical properties.

The study, published in the Journal of Advanced Joining Processes, focuses on friction stir processing (FSP), a technique that uses heat and mechanical stirring to blend materials at a molecular level. Oliaei and her team explored how pre-deformation through asymmetric rolling and varying rotational speeds during FSP affect the microstructure and performance of tungsten-reinforced copper matrix composites.

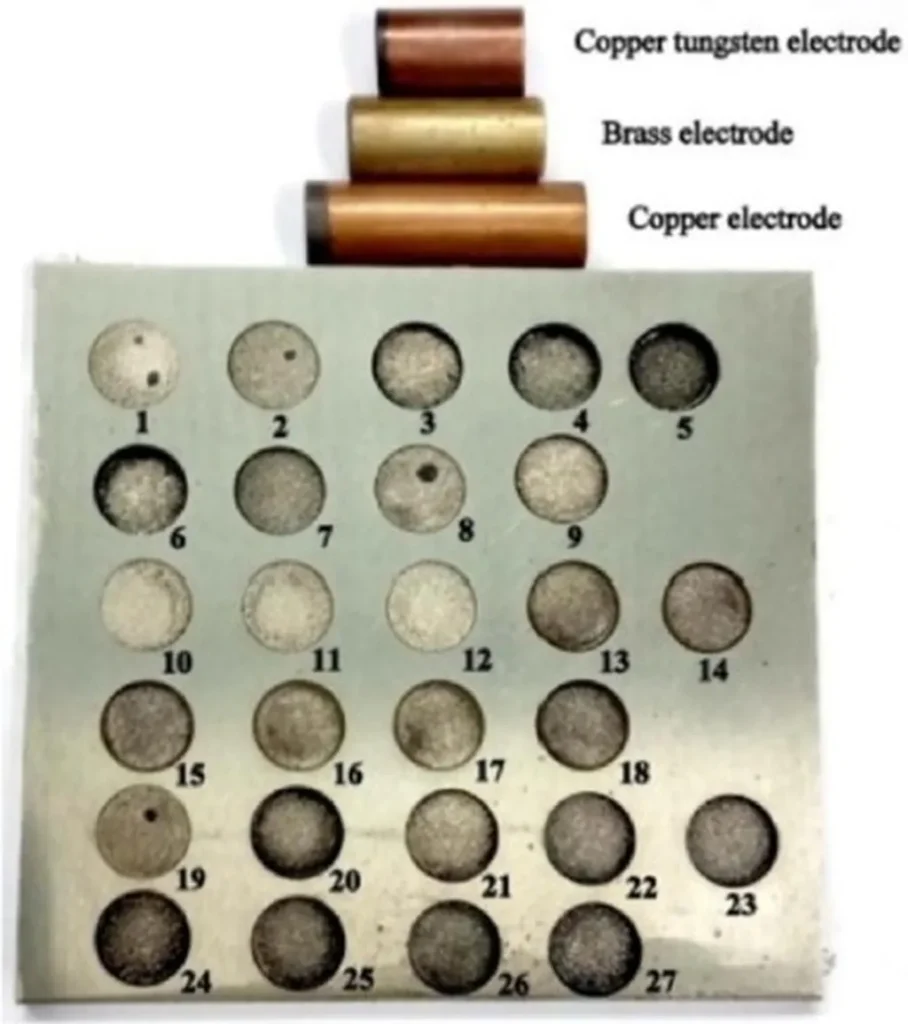

The findings are nothing short of transformative. By tweaking the rotational speed during FSP, the researchers discovered they could control the distribution of tungsten particles within the copper matrix. “At 800 rpm, we observed a remarkable uniformity in the distribution of tungsten particles,” Oliaei explained. “This uniformity is key to enhancing the composite’s overall performance.”

The implications for the energy sector are profound. Copper-tungsten composites are prized for their exceptional electrical conductivity and mechanical strength, making them ideal for high-performance applications such as electrical contacts, heat sinks, and even nuclear fusion reactors. The ability to fine-tune these properties through FSP could lead to more efficient and durable components, reducing downtime and maintenance costs in power generation and transmission.

One of the most striking results was the significant improvement in electrical conductivity. The Cu-W composite processed at 800 rpm showed an 8.8% increase in electrical conductivity compared to the as-rolled copper-based metal. This enhancement could translate to more efficient power transmission, reducing energy losses and contributing to a more sustainable energy infrastructure.

The study also shed light on the microstructural changes induced by different rotational speeds. As the speed increased from 600 to 1200 rpm, the grain size in the stir zone grew, affecting the composite’s mechanical properties. However, the sweet spot seemed to be at 800 rpm, where the composite achieved the highest values in hardness, ultimate tensile strength, and tensile toughness.

Oliaei’s research, published in the Journal of Advanced Joining Processes, titled “Optimizing microstructure and performance: The impact of pre-deformation and rotational speed on friction stir processed Cu-W composites,” opens new avenues for material scientists and engineers. The ability to tailor the properties of copper-tungsten composites through FSP could revolutionize the way we design and manufacture components for the energy sector.

As the world continues to demand more efficient and sustainable energy solutions, innovations like these will be crucial. Oliaei’s work not only advances our understanding of material science but also paves the way for future developments in the field. The energy sector stands on the brink of a new era, where precision engineering and advanced materials could redefine what’s possible.