In the heart of China, researchers are revolutionizing the way we think about ultrafiltration membranes, and the implications for industries like energy and wastewater treatment are profound. At the forefront of this innovation is YANG Jing, a researcher from the School of Urban Planning and Municipal Engineering at Xi’an Polytechnic University. Her latest study, published in Xi’an Gongcheng Daxue xuebao (Journal of Xi’an University of Architecture and Technology), delves into the microstructure of modified polyvinylidene fluoride (PVDF) membranes and their enhanced resistance to organic dyes.

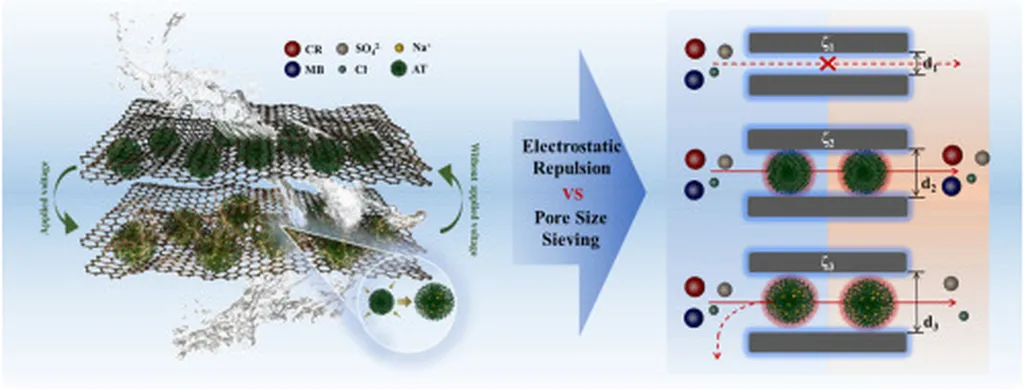

The quest to improve the pollution resistance of PVDF membranes has led YANG and her team to explore the use of polydopamine (PDA) as a modifier. By employing phase transformation methods and two different pore-forming agents—polyvinylpyrrolidone (PVP) and lithium chloride (LiCl)—they have uncovered significant advancements in membrane technology.

“The addition of PDA can greatly improve the pure water flux and dye retention rate of the PDA/PVDF membrane,” YANG explains. This enhancement is crucial for industries that rely on efficient filtration processes, such as those in the energy sector. For example, in the treatment of produced water from oil and gas operations, the ability to retain organic dyes and other contaminants is paramount. The improved hydrophilicity and increased average pore diameter of the PDA/PVDF membranes, particularly those using PVP, offer a promising solution.

One of the standout findings is the superior performance of the PDA/PVDF membrane using LiCl as the pore-forming agent. This membrane demonstrated an impressive retention rate of 87.05% for disperse deep blue HGL, a common dye used in various industrial processes. This level of retention is a game-changer for industries seeking to minimize environmental impact and maximize operational efficiency.

Moreover, the study revealed that the addition of PDA enhances the anti-pollution performance of the membranes. When the content of PDA was optimized to 1.6%, the flux recovery rate for reactive brilliant orange K-NG reached an astonishing 94.1%. This means that the membranes can maintain high performance even after repeated use, reducing the need for frequent replacements and lowering operational costs.

The implications of this research are far-reaching. For the energy sector, where wastewater treatment is a critical concern, these advanced membranes could lead to more sustainable and cost-effective solutions. The ability to retain organic dyes and other contaminants more effectively could also have significant environmental benefits, reducing the ecological footprint of industrial operations.

As YANG and her team continue to refine their methods, the future of ultrafiltration membranes looks brighter than ever. The use of PDA as a modifier, combined with the strategic use of pore-forming agents, opens up new possibilities for membrane technology. This research, published in Xi’an Gongcheng Daxue xuebao, is a testament to the innovative spirit driving advancements in the field. As industries strive for greater efficiency and sustainability, the work of YANG and her colleagues at Xi’an Polytechnic University is poised to play a pivotal role in shaping the future of membrane technology.