In the relentless pursuit of enhancing structural integrity and longevity, a groundbreaking study has emerged from the American University of Sharjah, promising to revolutionize the way we fortify reinforced concrete (RC) beams. Led by Maha Assad from the Department of Civil Engineering, this research delves into the behavior of RC beams strengthened with advanced materials under cyclic loading, a critical factor in the energy sector where structures often endure repetitive stress.

The energy industry, with its sprawling infrastructure and demanding operational conditions, stands to benefit immensely from these findings. Pipelines, offshore platforms, and power plants are just a few examples of structures that face cyclic loading, where repeated stress can lead to fatigue and eventual failure. Assad’s research offers a beacon of hope, demonstrating that external bonded reinforcement (EBR) can significantly bolster the resilience of these critical assets.

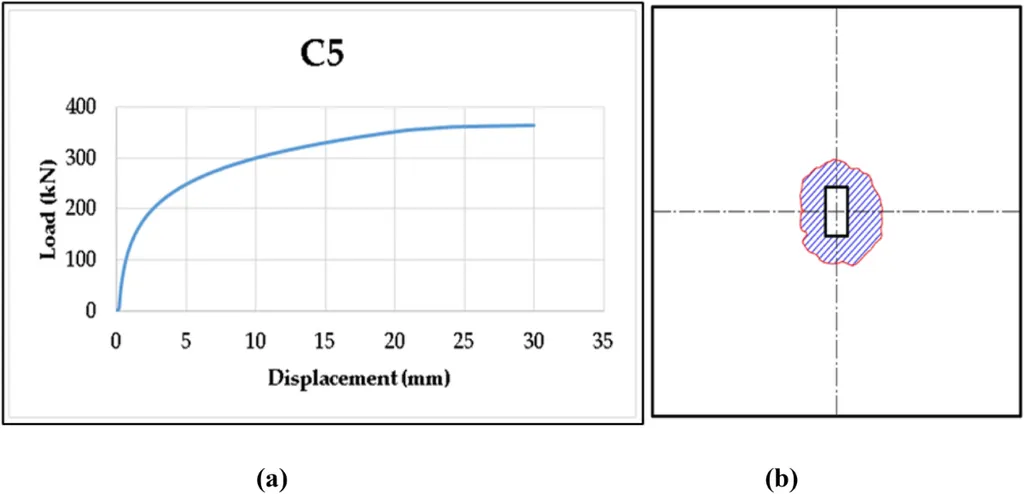

The study, published in the journal Composites Part C: Open Access, which translates to Composites Part C: Open Access in English, tested four beam configurations: a control beam and three strengthened with carbon fiber-reinforced polymer (CFRP) sheets, steel mesh sheets bonded with epoxy (SME), and steel mesh sheets bonded with mortar (SMM). The results were striking. “The strengthened beams exhibited larger hysteresis loop areas, reflecting their enhanced energy absorption and dissipation capacity,” Assad explained. This means that the strengthened beams could withstand more stress and strain, absorbing and dissipating energy more effectively than the control beam.

But the standout performer was the SMM beam, which consistently outperformed the others. It achieved the highest flexural load-carrying capacity and dissipation energy, making it a promising candidate for real-world applications. Post-cyclic monotonic loading tests further cemented these findings, with strengthened beams showing a 38 to 51% increase in flexural strength compared to the control beam.

So, what does this mean for the energy sector? For starters, it opens up new avenues for extending the lifespan of existing structures. By retrofitting aging infrastructure with these advanced materials, energy companies can defer costly replacements and upgrades, saving both time and money. Moreover, it paves the way for designing more robust and resilient structures from the get-go, reducing the risk of failures and enhancing safety.

The implications of this research are far-reaching. As Assad puts it, “Strengthening significantly improves the behavior of RC beams under cyclic loading.” This could lead to a paradigm shift in how we approach structural reinforcement, not just in the energy sector, but across various industries. From bridges and buildings to tunnels and dams, the potential applications are vast.

Looking ahead, we can expect to see more innovative uses of CFRP and steel mesh sheets in construction. As the technology matures, we may even see new materials and methods emerging, further pushing the boundaries of what’s possible. The future of structural reinforcement is bright, and it’s being shaped by pioneering research like Assad’s.

For energy companies, the message is clear: investing in these advanced materials and techniques could yield significant dividends in the long run. It’s not just about building stronger structures; it’s about building smarter, more resilient ones that can withstand the test of time and the rigors of cyclic loading. The energy sector is on the cusp of a reinforcement revolution, and those who embrace it stand to gain the most.