In the realm of construction and infrastructure development, retrofitting and rehabilitation techniques are gaining significant traction. Among these, fiber reinforced polymer (FRP) and textile reinforced mortar (TRM) confinement systems have emerged as promising methods. A recent study published in the journal ‘Composites Part C: Open Access’ (which translates to ‘Composites Part C: Open Access’ in English) sheds light on the performance of these systems under elevated temperatures, offering insights that could reshape industry practices.

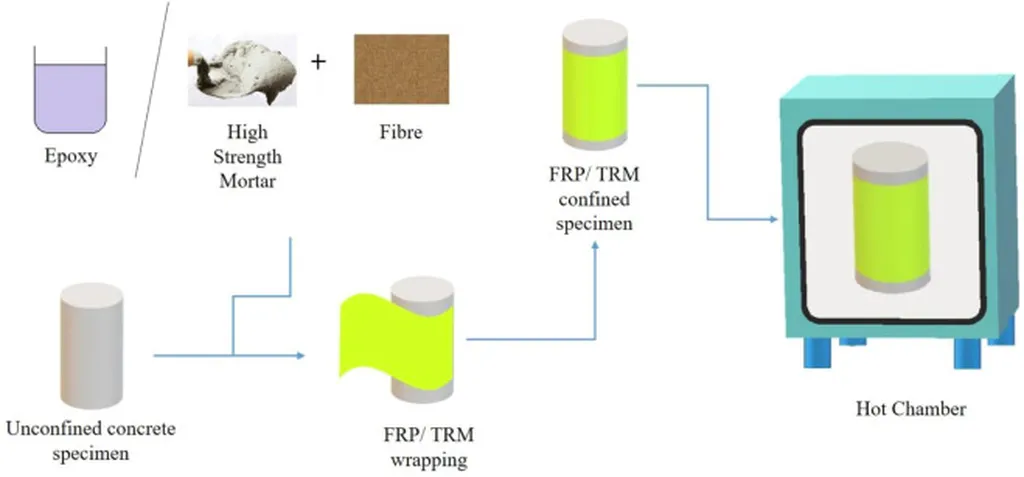

The research, led by D. Akhil Varma from the Department of Civil Engineering at Amrita School of Engineering, Coimbatore, Amrita Vishwa Vidyapeetham, India, compares the effectiveness of TRM and FRP systems in confining concrete cylinders exposed to high temperatures. The study utilized jute and basalt fibers as reinforcing agents, providing a comprehensive analysis of their performance.

The findings reveal that TRM systems demonstrated superior confinement efficiencies at various temperatures. “The addition of jute fibers in TRM showed a notable enhancement in residual strength, Young’s modulus, and failure strain at temperatures reaching 400 °C,” Varma explains. Basalt fiber-reinforced TRM systems, on the other hand, exhibited better thermal and fire resistance. Conversely, FRP systems, which consist of jute and basalt fibers, showed reduced mechanical properties and considerable degradation under high temperatures.

These results indicate that TRM systems offer a more efficient and dependable option for concrete confinement applications under high temperatures. This is particularly significant for the energy sector, where structures often face extreme thermal conditions. The exceptional efficiency of TRM confinement systems at high temperatures positions them as a viable substitute for conventional FRP confinement systems in structural applications in fire-sensitive environments.

The commercial implications of this research are substantial. As the demand for retrofitting and rehabilitation techniques grows, the construction industry can benefit from the enhanced performance and reliability of TRM systems. This could lead to more durable and safer structures, reducing maintenance costs and improving overall infrastructure resilience.

Moreover, the study’s findings could pave the way for future developments in the field. As Varma notes, “The exceptional efficiency of TRM confinement systems at high temperatures positions them as a viable substitute for conventional FRP confinement systems in structural applications in fire-sensitive environments.” This opens up new avenues for research and innovation, potentially leading to the development of advanced materials and techniques that can further enhance the performance of TRM systems.

In conclusion, this research offers valuable insights into the performance of TRM and FRP systems under elevated temperatures. The findings not only highlight the superior efficiency of TRM systems but also underscore their potential to revolutionize the construction industry. As the energy sector continues to evolve, the adoption of these advanced materials and techniques could play a crucial role in building more resilient and sustainable infrastructure.