In a significant stride towards sustainable resource recovery, researchers have developed an innovative method to extract vanadium from fly ash, a byproduct of thermal power plants. This breakthrough, led by Igor V. Mishin, offers a promising avenue for the energy sector to recover valuable metals from secondary sources, potentially reducing reliance on ore mining and enhancing the circular economy.

Vanadium, a critical element in the production of high-strength alloys, catalysts, and electrolytes for flow batteries, is traditionally extracted from ore deposits. However, the higher initial vanadium content in secondary sources like fly ash makes its extraction more cost-effective and resource-saving. “Due to the higher initial vanadium content in secondary sources compared to ore deposits, its extraction from the former appears to be a more cost-effective and resource-saving process,” Mishin explained.

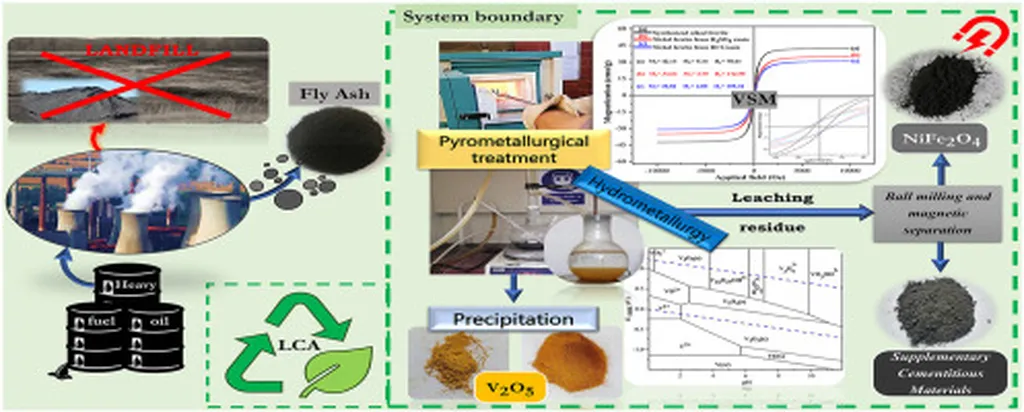

The study, published in the journal “Известия Томского политехнического университета: Инжиниринг георесурсов” (translated as “Proceedings of the Tomsk Polytechnic University: Engineering of Georesources”), focuses on leaching vanadium from fly ash using sulfuric acid and sodium sulfite as a reducing agent. This method enables the recovery of vanadium in the form of VOSO4, facilitating its further selective extraction.

The research team investigated various factors affecting leaching efficiency, including sulfuric acid concentration, reducing agent concentration, liquid/solid phase ratio, leaching time, and temperature. Their findings revealed that vanadium (>80%) and nickel (>65%) are predominantly recovered from fly ash, while iron and manganese mostly remain in the solid residue. The highest extraction efficiency (99.6%) for vanadium was achieved when treating ash with a solution of 1 M H2SO4 and 0.04 M Na2SO3 at 80°C for 30 minutes with an ash ratio of 4 ml/1 g.

“This study proposes a method for leaching vanadium from ash using a solution of sulfuric acid and the reducing agent sodium sulfite, enabling to obtain a concentrate of vanadium (IV) in the form of VOSO4 for its further selective extraction,” Mishin stated. The resulting leaching solution contains ions of iron, vanadium, nickel, and manganese, which require separation by physical and chemical methods.

The implications of this research are substantial for the energy sector. By optimizing the recovery of vanadium from fly ash, thermal power plants can transform a previously underutilized byproduct into a valuable resource. This not only enhances the economic viability of power generation but also contributes to environmental sustainability by reducing waste and promoting resource efficiency.

As the world increasingly focuses on circular economy principles, this research paves the way for innovative approaches to metal recovery. The method developed by Mishin and his team could inspire further advancements in the field, potentially leading to broader applications in the extraction of other valuable metals from industrial byproducts. The energy sector stands to benefit significantly from these developments, as the recovery of critical metals from secondary sources aligns with global efforts towards sustainability and resource efficiency.