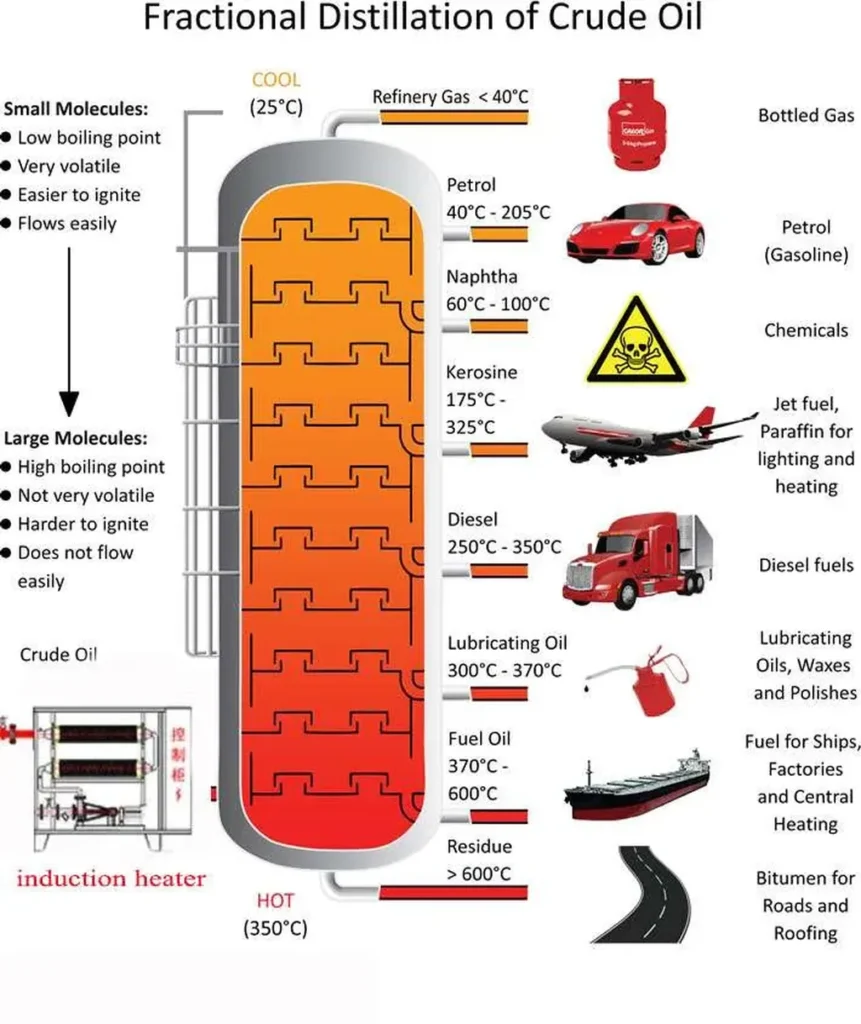

In the quest to enhance heavy oil extraction efficiency, researchers have turned to an innovative method that could revolutionize how the energy sector tackles a persistent problem: wax deposits. A recent study led by Denis V. Kosmylin from the Ufa University of Science and Technology explores the use of induction heaters to clean the near-wellbore zone of reservoirs, offering a promising solution to a longstanding challenge.

Wax deposits in the near-wellbore zone and wellhead are a significant hindrance to oil field development, reducing efficiency and increasing operational costs. Traditional methods of dealing with these deposits often fall short, prompting the need for more effective solutions. Kosmylin’s research, published in the journal “Известия Томского политехнического университета: Инжиниринг георесурсов” (Tomsk Polytechnic University Journal: Engineering of Georesources), delves into the potential of induction heating to address this issue.

The study combines numerical mathematical modeling and experimental research to understand the thermal processes in the near-wellbore zone during induction heating. “We proposed a mathematical model to calculate the non-stationary temperature field in the near-wellbore zone,” Kosmylin explains. This model allows for the computation of temperature dynamics over time on the casing wall and in the near-wellbore zone, providing valuable insights into the effectiveness of induction heating.

One of the key findings is that periodic induction exposure can create a thermal disturbance that propagates more than 0.5 meters into the reservoir over a 12-hour period. This means that the heating effect extends beyond the immediate vicinity of the well, potentially improving the flow of heavy oil. “We found that reservoir heating with a value of more than 5 degrees Celsius is achieved in the near-wellbore zone with a radius of 0.2–0.3 meters, depending on the thermal conductivity of the rocks,” Kosmylin notes.

To validate their numerical models, the researchers conducted experimental studies using a physical model of a well equipped with an induction heater. The results showed that reservoir heating of more than 1 degree Celsius was achieved within a radius of up to 0.25 meters. These findings demonstrate the feasibility of using induction heating to clean the near-wellbore zone from wax deposits, offering a practical and efficient solution for the energy sector.

The implications of this research are significant for the oil and gas industry. By improving the efficiency of heavy oil extraction, induction heating could lead to substantial cost savings and increased productivity. As the energy sector continues to seek innovative solutions to enhance operational performance, this study provides a compelling case for the adoption of induction heating technology.

Kosmylin’s work not only highlights the potential of induction heating but also sets the stage for future developments in the field. As researchers continue to refine and expand on these findings, the energy sector can look forward to more effective and efficient methods of tackling wax deposits, ultimately driving progress and innovation in heavy oil extraction.