In the realm of high-performance equipment manufacturing, the demand for thin-walled components has surged due to their exceptional strength-to-weight ratio. However, these components present a significant challenge during the milling process: chatter vibration. This vibration, caused by the weak rigidity and poor damping properties of thin-walled parts, can severely compromise surface quality and reduce machining productivity. Enter Yuwen Sun, a researcher from the State Key Laboratory of High-performance Precision Manufacturing at Dalian University of Technology, who has been delving into the intricacies of chatter suppression in thin-wall milling.

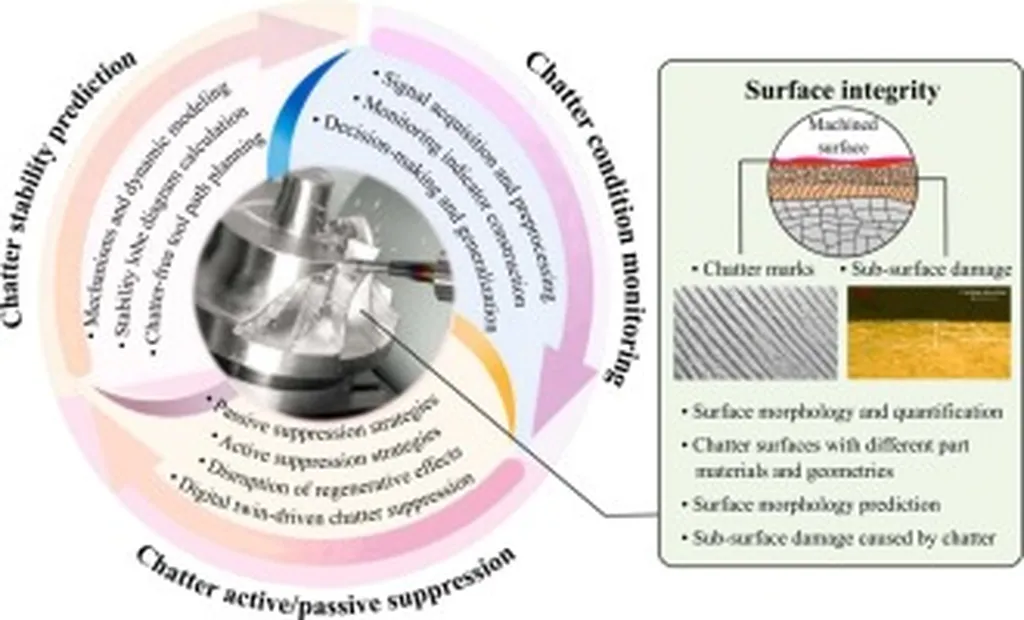

In a recent paper published in the *International Journal of Extreme Manufacturing* (which translates to *International Journal of Extreme Manufacturing*), Sun and his team have reviewed the current state of the art in chatter suppression techniques. Their work sheds light on the dynamic characteristics of thin-wall milling and the challenges associated with designing and applying effective chatter attenuation methods.

The team’s comprehensive review covers a range of chatter suppression techniques, including passive, active, and semi-active methods. Each technique is discussed in terms of its basic concepts, working mechanisms, optimal design, and practical applications. “Understanding these methods is crucial for improving the dynamic machinability of thin-walled structures,” Sun explains. “Our goal is to provide a roadmap for future research and development in this field.”

The implications of this research are particularly significant for the energy sector, where high-performance equipment often relies on thin-walled components. By enhancing chatter suppression techniques, manufacturers can improve the quality and productivity of these components, ultimately leading to more efficient and reliable energy systems.

Sun’s work also highlights the need for further innovation in chatter mitigation technology. “While significant progress has been made, there are still challenges to be addressed,” Sun notes. “Future research should focus on developing more robust and adaptable chatter suppression methods that can handle the complexities of modern manufacturing processes.”

As the energy sector continues to evolve, the demand for high-performance, lightweight components is only expected to grow. Sun’s research provides a crucial stepping stone towards meeting this demand, paving the way for more advanced and efficient manufacturing techniques in the future.