In the quest for stronger, lighter, and more efficient materials, researchers have long turned to composites, and now, graphene—a wonder material with extraordinary properties—is taking center stage. A recent review published in *Materials Research Express* (translated as “Materials Research Express”) by Huiyan Zhao of the Yingkou Institute of Technology in China sheds light on how graphene-reinforced composites are revolutionizing industries, particularly the energy sector.

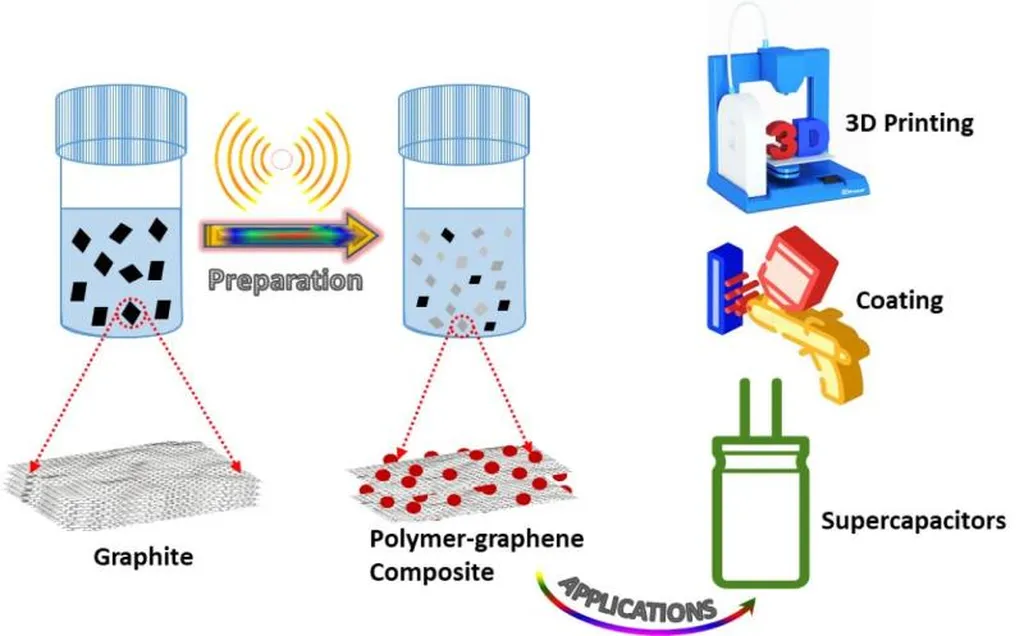

Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, is renowned for its exceptional mechanical strength, thermal conductivity, and electrical properties. When integrated into metal, ceramic, or polymer matrices, it creates composites that outperform traditional materials. Zhao’s review highlights the significant advancements in fabricating these composites, with a particular focus on the hot pressing method, a technique that uses heat and pressure to consolidate materials into a dense, solid form.

“The key to enhancing the properties of graphene-reinforced composites lies in the uniform dispersion of graphene within the matrix and the strength of the interfacial bonding,” Zhao explains. “Hot pressing is crucial here, as it allows us to control the temperature, pressure, and holding time to achieve optimal densification and performance.”

The review delves into the intricate details of the hot pressing process, discussing how varying parameters such as temperature and pressure can influence the final properties of the composite. For instance, higher temperatures can improve the diffusion of atoms, leading to stronger bonds, while excessive pressure can cause defects. By fine-tuning these parameters, researchers can tailor the composites to meet specific industrial needs.

One of the most compelling aspects of Zhao’s work is the integration of finite element analysis (FEA), a computational tool used to simulate and predict how materials behave under different conditions. “FEA allows us to visualize the temperature distribution, stress evolution, and material deformation during the hot-pressing process,” Zhao notes. “This not only saves time and resources but also provides valuable insights into the process-structure-property relationships.”

The implications for the energy sector are profound. Graphene-reinforced composites could lead to lighter, more durable wind turbine blades, enhancing energy efficiency and reducing maintenance costs. In the realm of energy storage, these materials could improve the performance of batteries and supercapacitors, enabling faster charging times and longer lifespans. Additionally, the enhanced thermal conductivity of these composites could revolutionize heat management systems in power plants and electronic devices.

As the world grapples with the challenges of climate change and the need for sustainable energy solutions, the development of high-performance materials like graphene-reinforced composites becomes increasingly vital. Zhao’s review not only highlights the current state of the art but also paves the way for future innovations, offering a roadmap for researchers and industry professionals alike.

In the words of Zhao, “The future of graphene-reinforced composites is bright, and with continued research and development, we can unlock their full potential to transform various industries, including energy.” As we stand on the brink of a materials revolution, the insights provided by this review could very well shape the next generation of advanced engineering applications.