In a breakthrough that could reshape the landscape of materials science, researchers have unveiled a novel strategy to significantly enhance the mechanical properties of titanium alloys. The study, led by Dr. Piotr Kwasniak from the Multidisciplinary Research Center at Cardinal Stefan Wyszynski University in Warsaw, Poland, introduces a microalloying technique that promises to maximize the strength-ductility combination in dilute titanium alloys. This advancement could have profound implications for industries, particularly in the energy sector, where the demand for high-performance materials is ever-growing.

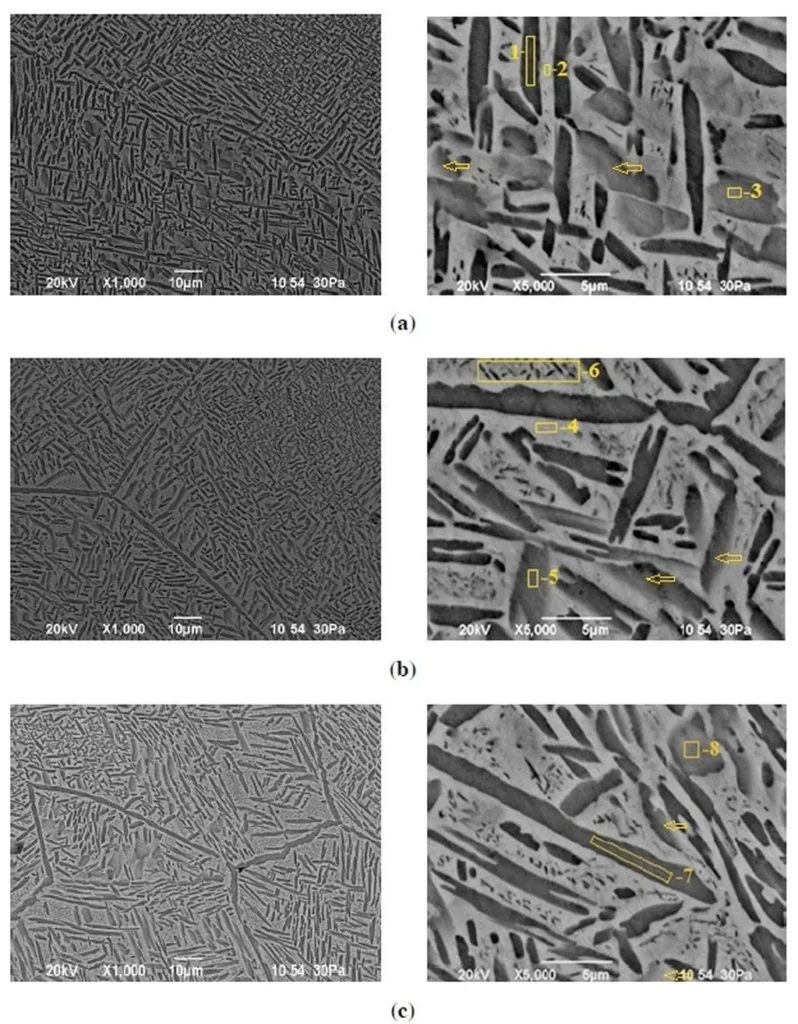

The research, published in the journal “Materials Research Letters” (translated from Polish as “Letters on Materials Research”), focuses on a highly effective microalloying strategy that activates a novel strengthening mechanism. By precipitating nanoscale β particles within the α matrix, the team achieved a remarkable 2.8 times increase in yield strength compared to pure titanium. This was accomplished while maintaining a high elongation of approximately 35% at a mere 0.5 wt.% (0.13 at.%) rhenium content.

Dr. Kwasniak explained, “Our approach leverages the unique properties of rhenium as a strong beta-stabilizer. By introducing it in small quantities, we can induce precipitation strengthening, which significantly enhances the material’s strength without compromising its ductility.” This dual enhancement of strength and ductility is a critical factor for applications in demanding environments, such as those encountered in the energy sector.

The implications of this research extend beyond the use of rhenium. Dr. Kwasniak and his team believe that similar properties can be achieved using other strong beta-stabilizers, making this method a universal way to improve the mechanical properties of titanium-based materials. This versatility could open new avenues for material design and application, particularly in industries where weight reduction and high performance are paramount.

The energy sector, in particular, stands to benefit from this innovation. Titanium alloys are already widely used in various energy applications due to their excellent corrosion resistance and high strength-to-weight ratio. The enhanced mechanical properties achieved through this microalloying technique could lead to the development of more efficient and durable components for energy generation and storage systems.

Dr. Kwasniak further elaborated, “The ability to tailor the mechanical properties of titanium alloys through microalloying offers a promising pathway for developing next-generation materials. This could revolutionize the way we design and manufacture components for energy applications, leading to more robust and efficient systems.”

As the energy sector continues to evolve, the demand for advanced materials that can withstand extreme conditions and deliver superior performance will only grow. The research conducted by Dr. Kwasniak and his team represents a significant step forward in meeting this demand. By providing a universal method to enhance the mechanical properties of titanium alloys, this study paves the way for future developments in materials science and engineering.

In conclusion, the novel microalloying strategy presented in this research offers a compelling solution to the long-standing challenge of balancing strength and ductility in titanium alloys. With its potential to transform the energy sector and beyond, this breakthrough underscores the importance of continued innovation in materials science. As Dr. Kwasniak aptly put it, “The future of materials lies in our ability to understand and manipulate their fundamental properties at the nanoscale. This research is a testament to that principle.”