In a significant stride towards enhancing the structural integrity of reinforced concrete beams, researchers have developed a novel finite element method that promises to revolutionize the analysis of fiber-reinforced concrete elements. This breakthrough, led by Alexey S. Markovich from RUDN University, focuses on beams with non-uniform steel fiber reinforcement, a common yet challenging material in modern construction.

The study, published in the journal “Structural Mechanics of Engineering Constructions and Buildings” (translated from Russian as “Stroitel’naya Mekhanika Inzhenernykh Konstruktcii i Sooruzhenii”), introduces a physically nonlinear finite element model that can accurately calculate displacements, strains, and stresses in characteristic layers of multilayer reinforcement beams. This advancement is crucial for the energy sector, where the durability and safety of structures are paramount.

“Our method allows for a more precise understanding of the stress-strain state of bent heterogeneous fiber-reinforced concrete elements,” Markovich explained. “This is particularly important for the energy sector, where structures often face complex loading conditions and require robust, reliable materials.”

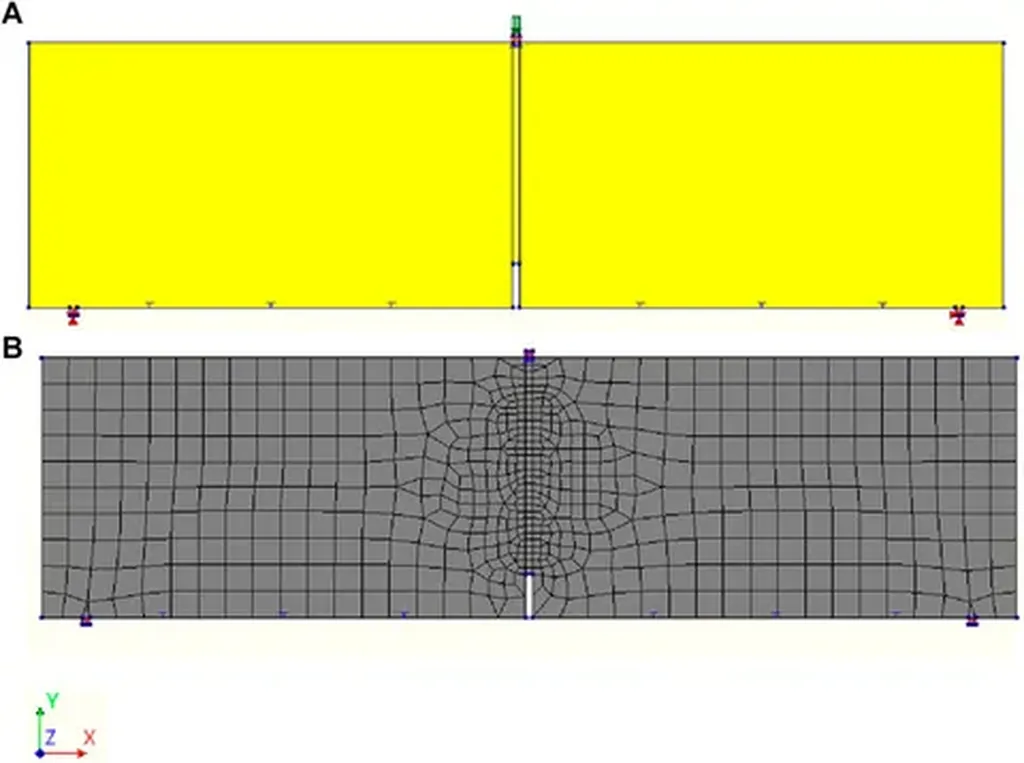

The research involved an experimental study of a steel-fiber-concrete beam with varying fiber reinforcement along the cross-section height, ranging from 0.5 to 2.0%. The experimental data obtained were used to verify the finite element model, which was developed based on the modified theory of multilayer beams proposed by P.M. Varvak. The model accounts for the curvature of the cross-section under shear stresses, providing a more comprehensive analysis.

“By integrating our finite element into the PRINCE computing complex, we can now offer a powerful tool for calculating heterogeneous fiber-reinforced elements,” Markovich added. “This will not only enhance the design process but also ensure the safety and longevity of structures in the energy sector.”

The study also compared the results obtained from the developed finite element with those from the Ansys software package. The discrepancy between the calculation results and the experimental data ranged from 6 to 11%, and from 11 to 15% with the Ansys results. This level of accuracy is a testament to the robustness of the new method.

The implications of this research are far-reaching. By providing a more accurate and efficient way to analyze reinforced concrete beams, the energy sector can design structures that are not only stronger but also more cost-effective. This could lead to significant savings in material and construction costs, as well as improved safety standards.

As the energy sector continues to evolve, the demand for advanced materials and innovative design methods will only grow. This research by Markovich and his team at RUDN University is a significant step forward in meeting these demands, paving the way for safer, more efficient, and more sustainable structures in the energy sector.