In the quest for sustainable construction materials, researchers have long been exploring the potential of geopolymer concrete (GPC), a eco-friendly alternative to traditional concrete. Now, a study published in the *Electronic Journal of Structural Engineering* (translated from Russian as *Electronic Journal of Structural Mechanics*) offers promising insights into enhancing the performance of GPC using industrial by-products, with significant implications for the energy sector.

Jay Bhavsar, a researcher at Charotar University of Science and Technology, led a study that investigated the heat and abrasion resistance of geopolymer mortar (GM) incorporating ceramic polishing waste (CPW). The study focused on two types of CPW: vitrified tile CPW (VCPW) and wall tile CPW (WCPW), which are typically discarded as waste from the vitrified and wall tile polishing processes.

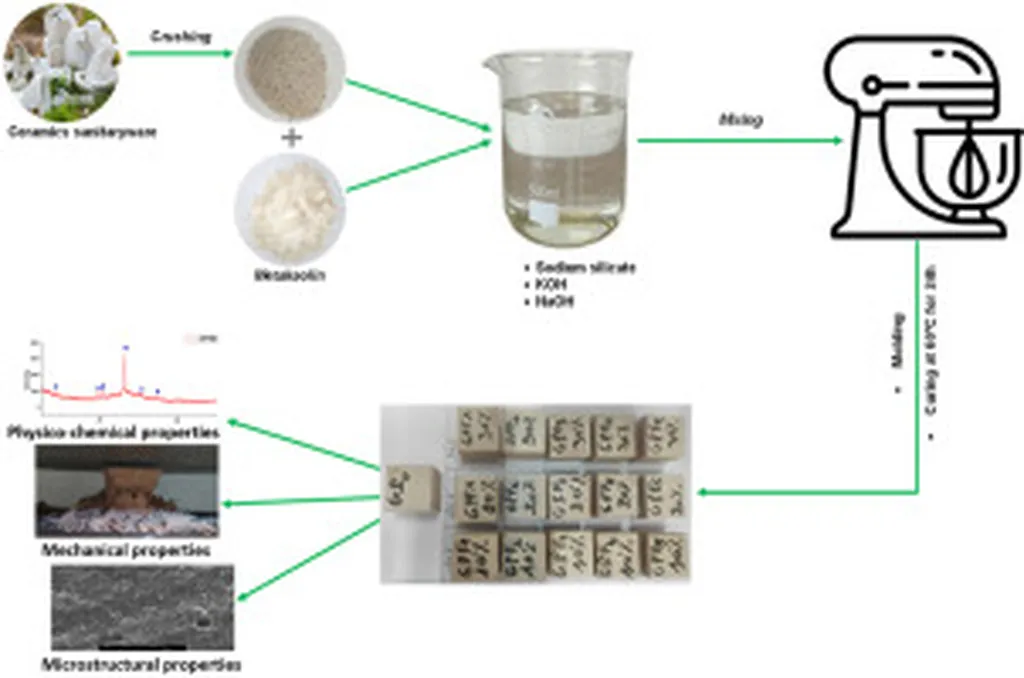

The research team found that replacing fly ash (FA) with 15% CPWs improved early-age compressive strength and abrasion resistance, while also maintaining similar performance in heat resistance at 1000°C. “The curing conditions played a crucial role in the performance of the geopolymer mortar,” Bhavsar explained. “We observed that curing at 60°C for 48 hours significantly enhanced the early-age compressive strength and fire exposure performance at 500°C.”

The study also delved into the microstructure of the geopolymer after heat exposure, using scanning electron microscopy (SEM). The findings revealed additional geopolymerization due to heat exposure and reduced degradation of the gel. This suggests that the incorporation of CPWs not only enhances the mechanical properties of GM but also improves its durability under high-temperature conditions.

The commercial impacts of this research are substantial, particularly for the energy sector. The enhanced heat and abrasion resistance of GM can lead to more durable and sustainable construction materials for energy infrastructure, such as power plants and industrial facilities. “This research opens up new possibilities for utilizing industrial by-products in the construction industry,” Bhavsar noted. “It’s a step towards a more sustainable and circular economy.”

The findings also highlight the importance of optimizing curing conditions to achieve the desired properties in geopolymer mortar. This could lead to more efficient and cost-effective production methods for GPC, making it a more viable alternative to traditional concrete.

As the construction industry continues to seek sustainable and durable materials, the research by Bhavsar and his team offers valuable insights into the potential of geopolymer concrete. The study not only advances our understanding of the properties of GM but also paves the way for future developments in the field. With further research and innovation, geopolymer concrete could become a cornerstone of sustainable construction, reducing the environmental impact of the industry and contributing to a more sustainable future.