In the quest to enhance the durability and safety of pipelines, a groundbreaking study led by Mingming Quan from the School of Material Science and Engineering at Hebei University of Science and Technology in China has unveiled a novel approach to improving the impact toughness of X80 pipeline steel welds. Published in the esteemed journal *Materials & Design* (translated to English as “Materials & Design”), this research could have significant implications for the energy sector, particularly in harsh environments where pipeline integrity is paramount.

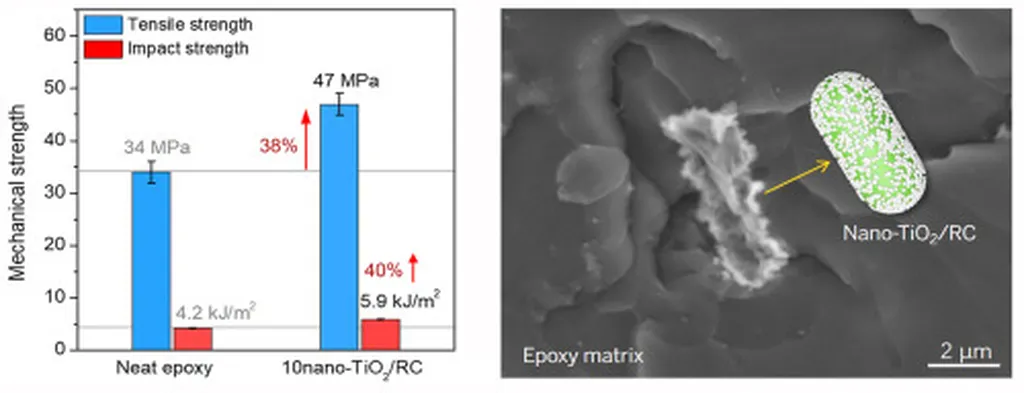

The study focused on the addition of titanium dioxide (TiO2) nanoparticles to the weld pool during the pulsed MAG (Metal-Active Gas) welding process. The results were striking: the welds exhibited a marked improvement in impact toughness, with an average increase of 22.06% at -40°C. This enhancement is attributed to the formation of acicular ferrite (AF), a microstructure known for its superior toughness.

“Our findings demonstrate that the addition of nano-TiO2 not only refines the weld microstructure but also promotes the nucleation of acicular ferrite,” Quan explained. “This dual effect significantly improves the weld’s ability to resist crack propagation, which is crucial for the longevity and safety of pipelines.”

The research revealed that the nano-TiO2 particles facilitate AF nucleation through two mechanisms: the Mn-depletion zone (MDZ) mechanism and the low lattice mismatch mechanism. The oxides formed, primarily composed of Ti-Mn-O-Si-Al, act as nucleation sites for AF, leading to a finer and more robust microstructure. The average grain size of the weld was reduced from 7.14 μm to 5.14 μm, further contributing to the improved impact toughness.

The commercial implications of this research are substantial. Pipelines, especially those operating in extreme environments, are subject to significant stress and strain. Enhancing their toughness can prevent catastrophic failures, reduce maintenance costs, and ensure the safe transportation of energy resources. “This research opens up new avenues for developing high-performance welding materials,” Quan noted. “It could revolutionize the way we construct and maintain pipelines, making them more resilient and reliable.”

As the energy sector continues to push the boundaries of efficiency and safety, innovations like this are pivotal. The study’s findings could pave the way for advanced welding techniques and materials that meet the demanding requirements of modern pipeline infrastructure. With the energy sector’s increasing focus on durability and safety, this research is a significant step forward, offering a glimpse into the future of pipeline construction and maintenance.