In the high-stakes world of aerospace, nuclear engineering, and transportation, the demand for robust, high-performance materials is relentless. Enter fiber-reinforced ceramic matrix composites (FRCMCs), the unsung heroes of safety-critical components. These materials, with their impressive strength and heat resistance, are increasingly becoming the go-to choice for industries where failure is not an option. However, their fabrication and machining present significant challenges, a gap that a recent study published in the *International Journal of Extreme Manufacturing* (translated as “International Journal of Extreme Manufacturing”) aims to bridge.

Led by Shuoshuo Qu from Shandong University, the research delves into the intricate world of FRCMCs, offering a comprehensive review of their fabrication and machining processes. Qu, affiliated with the Key Laboratory of High-efficiency and Clean Mechanical Manufacture, highlights the urgent need to address issues such as poor adhesion, high porosity, and crack propagation. “With the increasing demand for FRCMCs parts, high-quality and reliable design and fabrication, performance evaluation, and precision manufacturing have become a series of hot issues,” Qu notes.

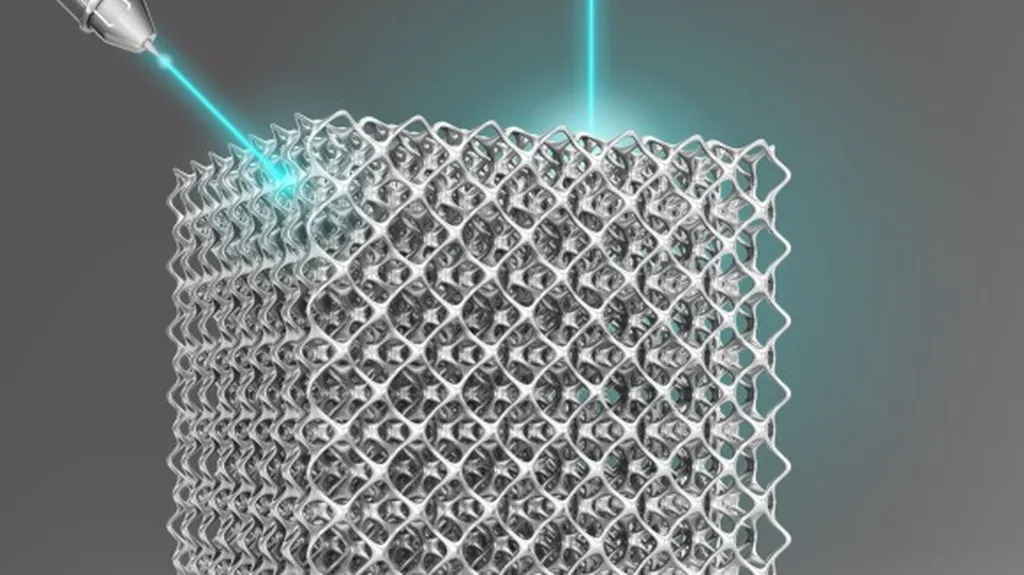

The study meticulously compares and analyzes typical fabrication processes, evaluating their advantages, disadvantages, and performance. It also explores material removal mechanisms and machining performance evaluation standards, covering both traditional mechanical machining technologies like drilling, milling, and grinding, and non-traditional methods such as ultrasonic, laser, water jet, discharge, wire saw, and multi-field hybrid machining.

The implications of this research for the energy sector are profound. As the world pivots towards cleaner energy solutions, the demand for high-performance materials that can withstand extreme conditions is set to soar. FRCMCs, with their exceptional properties, are poised to play a pivotal role in this transition. However, their widespread adoption hinges on overcoming the challenges in their fabrication and machining, a hurdle that this study aims to address.

Qu’s research not only elucidates the basic processes and key difficulties in the fabrication of FRCMCs but also provides valuable insights for low-damage machining. By offering a deeper understanding of the shape control mechanism of FRCMCs fabrication and machining, the theoretical basis of material synchronous removal, and machining performance, the study paves the way for future developments in the field.

As the energy sector continues to evolve, the insights gleaned from this research could prove instrumental in shaping the materials of the future. By addressing the critical issues in FRCMCs fabrication and machining, Qu and his team are contributing to the development of high-performance materials that could redefine the boundaries of what’s possible in the energy sector.