In the ever-evolving world of construction materials, a groundbreaking study led by I. Ahmed from the Department of Civil Engineering at the Indian Institute of Technology, Roorkee, is set to revolutionize how we evaluate the quality of cement mortar. Published in the esteemed journal, “The International Archives of the Photogrammetry, Remote Sensing and Spatial Information Sciences” (translated as “International Archives of Photogrammetry, Remote Sensing and Spatial Information Sciences”), this research introduces a non-destructive method for assessing mortar quality, potentially saving time and resources in the construction industry.

Cement mortar, a fundamental material in construction, has long been evaluated through destructive testing methods, which are not only time-consuming but also result in the loss of the tested material. Ahmed’s study, however, offers a promising alternative. By utilizing hyperspectral remote sensing methods, the research investigates the spectral characteristics and compressive strength of cement mortar mixes with varying cement-to-sand ratios over different curing periods.

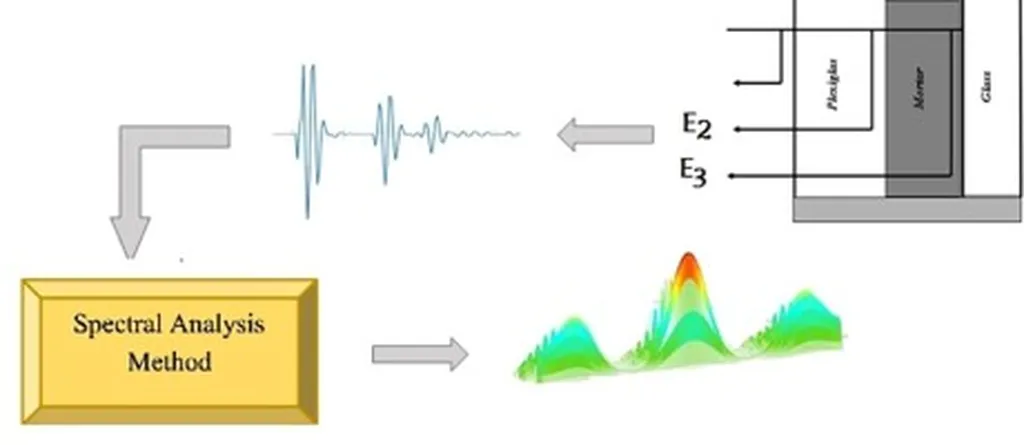

The study employed an SVC HR-1024i field spectroradiometer to conduct spectral reflectance measurements on mortar cubes, while compressive strength tests were performed using a Universal Testing Machine. The results were striking. “We found a strong correlation between mix composition, curing duration, and both reflectance and strength developed with time,” Ahmed explained. Higher cement content resulted in increased compressive strength and reflectance, particularly on the top surfaces of the samples. Moreover, spectral reflectance values increased with curing time, indicating the influence of hydration and microstructural densification on surface characteristics.

This research is not just a scientific breakthrough but also a practical solution for the construction industry. By introducing spectral analysis as a non-destructive method for evaluating mortar quality, it offers a practical alternative to traditional strength testing approaches. “This method can contribute to improved quality control in construction materials,” Ahmed noted, highlighting the significant differences in reflectance based on mix proportions and curing conditions.

The implications of this research extend beyond the construction industry. In the energy sector, where concrete structures are integral to infrastructure, this non-destructive testing method could enhance the efficiency and accuracy of material evaluation. It could lead to faster project completion times, reduced material waste, and ultimately, lower costs.

As we look to the future, Ahmed’s research paves the way for further exploration of non-destructive testing methodologies. It challenges the status quo and encourages innovation in how we assess and ensure the quality of construction materials. In a world where time and resources are precious commodities, this study offers a glimpse into a more efficient and sustainable future for the construction industry and beyond.