In the ever-evolving landscape of materials science, a recent study published in the Wasit Journal of Engineering Sciences (translated from Arabic as “The Journal of Engineering Sciences”) has shed new light on the correlation between Nanoindentation and Vickers hardness tests, offering promising implications for industries such as energy, where material performance is paramount. The research, led by Ammar Dawood Ghali Al-Rubaye, delves into the intricate world of material hardness testing, providing insights that could revolutionize how we understand and utilize different hardness tests.

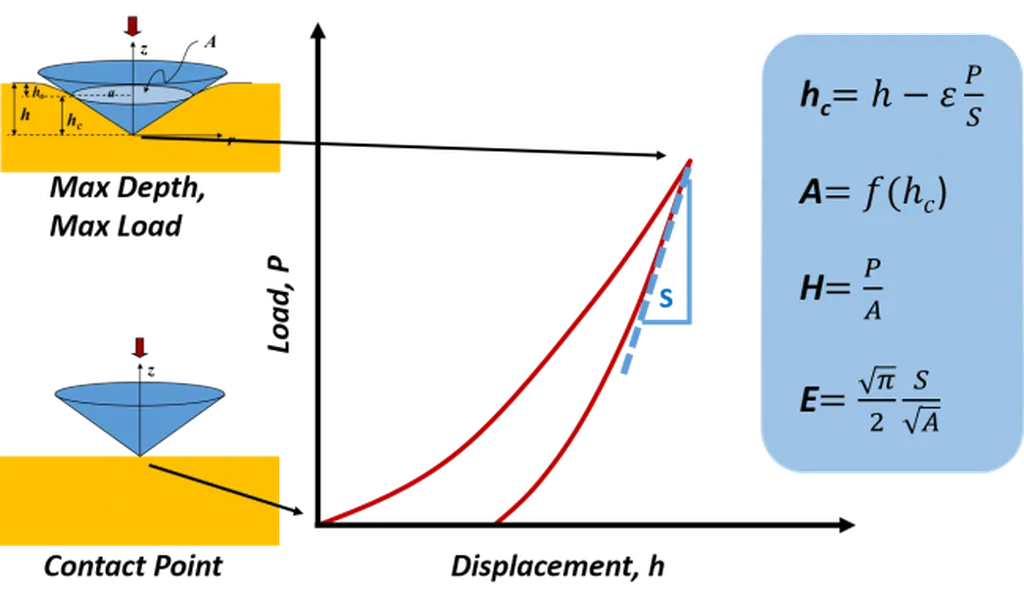

Hardness testing is a critical aspect of material characterization, particularly in sectors like energy, where materials are subjected to extreme conditions. Traditional Vickers hardness tests have long been a staple in this field, but they may not always accurately represent materials with plastic deformation resistance or those requiring narrow area testing. Enter Nanoindentation, a more versatile and precise method that can correlate to a broader range of mechanical properties.

Al-Rubaye’s research focused on three distinct materials: Ti6Al4V, pure copper, and AISI316 stainless steel. By applying a mathematical model based on the projected surface area resulting from indenter penetration, the study aimed to establish a correlation between Vickers hardness and Nanoindentation results. The findings were compelling. “We found that Nano-hardness and Vickers hardness can indeed be correlated,” Al-Rubaye explained. “However, the accuracy of this correlation hinges on the precise measurement of the projected area.”

The study revealed that Ti6Al4V exhibited the largest differential between practical and theoretical Micro-hardness and Nano-hardness results, at 43% and 37%, respectively. On the other hand, copper showed the lowest differential, with 30% and 33%. These findings could have significant implications for the energy sector, where materials like Ti6Al4V are often used in critical components such as turbines and pipelines.

The ability to correlate results from different hardness tests offers flexibility and efficiency in material testing. This could lead to more accurate material characterization and, ultimately, better-performing components in energy applications. As Al-Rubaye noted, “This research provides a foundation for future studies to build upon, potentially leading to more advanced and reliable hardness testing methods.”

The study’s findings could also pave the way for more efficient and cost-effective material testing processes. By understanding the correlation between different hardness tests, industries could reduce the need for multiple tests, saving time and resources. This is particularly relevant in the energy sector, where the demand for high-performance materials is ever-increasing.

In conclusion, Al-Rubaye’s research published in the Wasit Journal of Engineering Sciences offers valuable insights into the correlation between Nanoindentation and Vickers hardness tests. The findings have the potential to shape future developments in material testing, benefiting industries like energy that rely on high-performance materials. As the field continues to evolve, this research serves as a reminder of the importance of understanding and utilizing different hardness testing methods to ensure material performance and reliability.