In a groundbreaking development poised to revolutionize bone implantation and beyond, researchers have unveiled a new breed of superelastic nickel-titanium (NiTi) scaffolds that could redefine the boundaries of medical engineering and metamaterials. The study, led by Shiyu Zhong of the City University of Hong Kong Matter Science Research Institute in Shenzhen and the Department of Mechanical Engineering at City University of Hong Kong, introduces scaffolds with unparalleled adaptability and performance, offering a versatile solution for diverse bone implantation needs and other advanced applications.

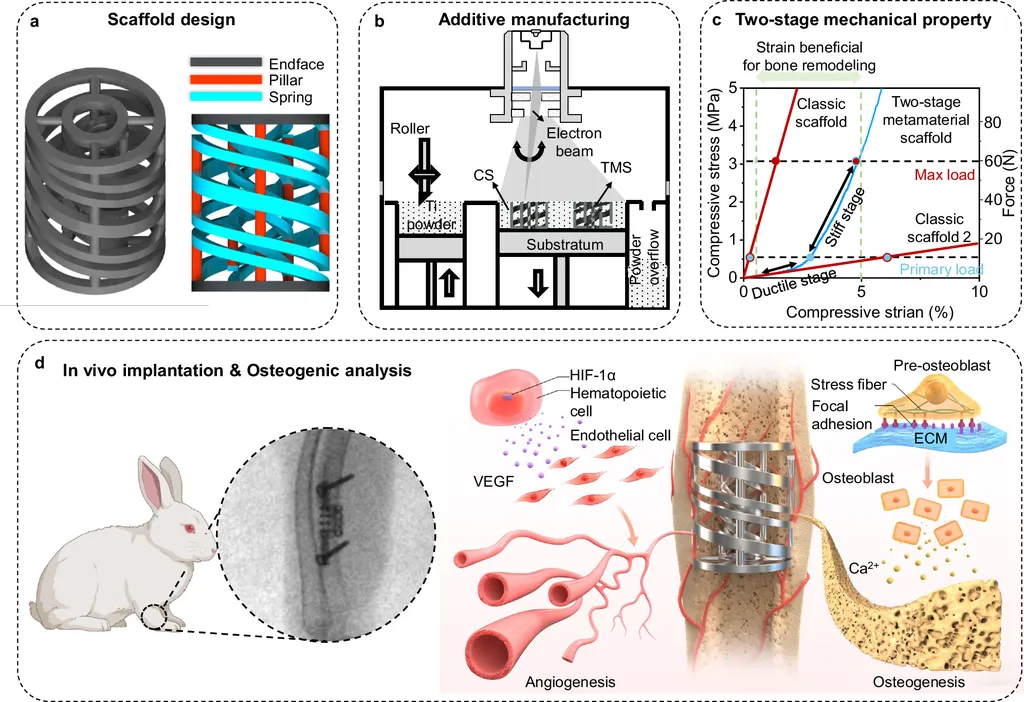

The innovative scaffolds boast a remarkable recoverable strain of 6%–7%, significantly surpassing the 2%–4% exhibited by natural bones. This substantial improvement is coupled with extensive tuneability in elastic modulus, cyclic stress, compressive strength, specific damping capacity, and permeability. The key to this impressive performance lies in the carefully designed structures featuring stable austenite phases with hierarchical microstructures and gyroid-sheet macrostructures. These unique structural combinations promote martensitic transformation during deformation, allowing engineers to fine-tune mechanical and mass transfer properties without compromising superelasticity.

“Our research demonstrates that by integrating these specific structural features, we can create scaffolds that are not only highly adaptable but also maintain their superelastic properties under various conditions,” Zhong explained. “This adaptability is crucial for addressing the diverse mechanical and biological requirements of different bone implantation scenarios.”

The implications of this research extend far beyond the medical field. The insights gained from developing these deformation-recoverable and performance-tuneable NiTi scaffolds could pave the way for advanced multifunctional metamaterials applicable in various industries, including energy. For instance, the tuneable mechanical properties and enhanced damping capacities could lead to more efficient and resilient energy absorption systems, improving the performance and longevity of renewable energy infrastructure.

“Imagine energy absorption systems that can adapt to different environmental conditions, enhancing their efficiency and durability,” Zhong added. “This is just one of the many potential applications that our research could inspire.”

The study, published in the International Journal of Extreme Manufacturing (which translates to “International Journal of Extreme Manufacturing” in English), highlights the potential for these scaffolds to offer a versatile solution for diverse bone implantation needs and other advanced applications. The integration of these unique structural features not only promotes martensitic transformation during deformation but also allows for the tuning of mechanical and mass transfer properties without compromising superelasticity.

As the world continues to seek innovative solutions to complex engineering challenges, the development of these superelastic NiTi scaffolds represents a significant step forward. By pushing the boundaries of what is possible in materials science, this research could shape the future of medical engineering, energy systems, and beyond, offering a glimpse into a world where materials are not just static components but dynamic, adaptable solutions.