In the quest for sustainable construction, a recent study has shed light on the environmental impacts of concrete, the world’s most widely used building material. Balamurali Kanagaraj, a researcher from the Department of Civil Engineering at Karunya Institute of Technology and Sciences in Coimbatore, India, has conducted a comprehensive life-cycle assessment (LCA) of concrete, comparing the use of natural and recycled aggregates. The findings, published in the journal “Case Studies in Chemical and Environmental Engineering” (translated as “Case Studies in Chemical and Environmental Engineering”), offer valuable insights for the construction and energy sectors.

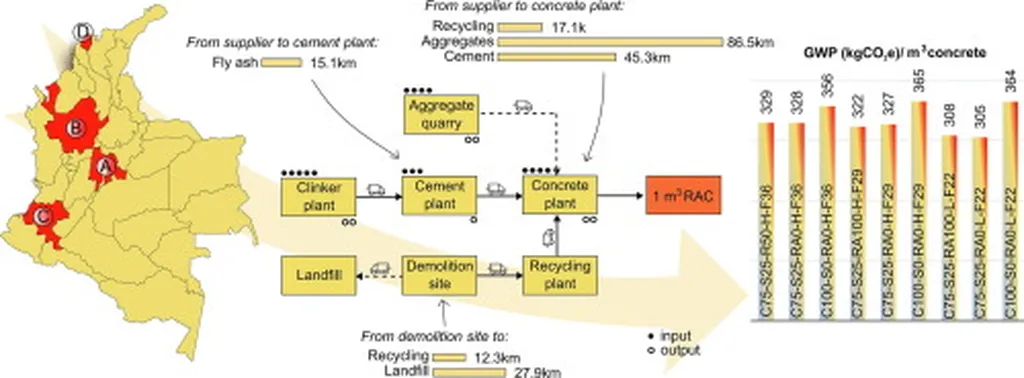

Concrete production is a significant contributor to greenhouse gas emissions (GHG-e) and energy consumption. Kanagaraj’s study focused on two types of concrete, M30 and M50, with varying strengths. By replacing natural aggregates with recycled aggregates (RA) sourced from demolished buildings, the research team aimed to assess the sustainability performance of concrete throughout its life cycle, from material procurement to final disposal.

The study found that incorporating recycled aggregates into concrete mixes can lead to substantial environmental benefits. “We observed a nearly 17% lower GHG-e for M30 grade concrete compared to M50 grade concrete,” Kanagaraj explained. This reduction is attributed to the lower energy requirements and emissions associated with processing recycled aggregates compared to extracting and processing natural aggregates.

The research also highlighted the environmental impacts of concrete disposal and recycling at the end of its service life. The GHG-e and embodied energy (EE) associated with demolition, loading, and transportation of demolished material were found to be 4.62 kg-CO2/m3 and 63.67 MJ/m3, respectively. These findings underscore the importance of considering the entire life cycle of concrete in sustainability assessments.

The commercial implications of this research are significant for the energy sector. As the demand for sustainable construction materials grows, the use of recycled aggregates in concrete production can help reduce energy consumption and greenhouse gas emissions. This can contribute to the achievement of energy efficiency targets and support the transition to a low-carbon economy.

Moreover, the findings of this study can inform policy decisions and industry practices aimed at promoting circular economy principles in the construction sector. By encouraging the use of recycled materials and optimizing the life-cycle performance of concrete, stakeholders can work towards a more sustainable and resilient built environment.

As the construction industry continues to evolve, research like Kanagaraj’s plays a crucial role in shaping future developments. By providing a comprehensive assessment of the environmental impacts of concrete, this study offers valuable insights for engineers, architects, policymakers, and industry professionals seeking to advance sustainability in the built environment.