In the depths of the ocean, where traditional rigid robots often struggle, a new wave of innovation is making waves—literally. Researchers are diving headfirst into the world of underwater soft robotics, and their findings could revolutionize how we approach offshore energy and underwater exploration. At the forefront of this research is Shahid A. Hasib from the Engineering of Complex Systems department at the University of Toulon in France. His recent study, published in the journal *Engineering Science and Technology, an International Journal* (translated from French as *Engineering Science and Technology, an International Journal*), offers a comprehensive look at the latest advancements in this burgeoning field.

Underwater environments present unique challenges—corrosion, pressure, and delicate ecosystems that demand gentle interaction. Traditional robots, with their rigid structures, often fall short in these conditions. Enter soft robotics: flexible, adaptable, and designed to mimic the very creatures that thrive in the ocean. “Soft robotics provides a distinct advantage in underwater applications due to its flexibility and adaptability,” explains Hasib. “These robots can navigate complex environments and interact safely with fragile ecosystems, making them ideal for tasks like offshore inspections and maintenance.”

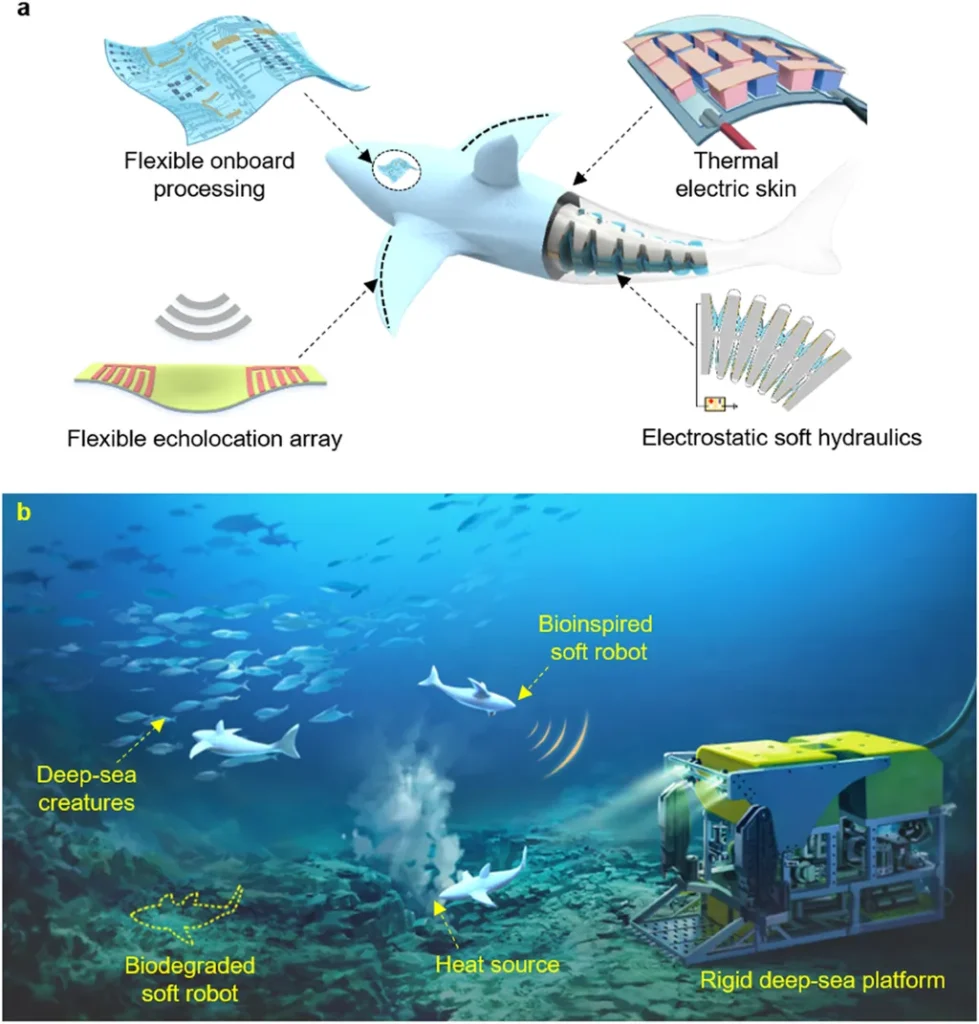

The study highlights several key advancements in the field. Bio-inspired actuators, for instance, mimic the movements of marine life, allowing robots to swim and maneuver with unprecedented efficiency. Smart materials, such as shape-memory alloys and electroactive polymers, enhance responsiveness and durability, ensuring these robots can withstand the harsh conditions of the deep sea. “The integration of smart materials is a game-changer,” says Hasib. “It allows us to create robots that are not only more responsive but also more resilient in dynamic aquatic conditions.”

One of the most exciting aspects of this research is the exploration of innovative fabrication techniques. 3D printing and soft lithography are revolutionizing the design and construction of underwater robots, enabling researchers to create complex, customizable structures with ease. These advancements could significantly reduce the cost and time associated with developing underwater robotic systems, making them more accessible for commercial applications.

For the energy sector, the implications are profound. Offshore wind farms, underwater pipelines, and subsea infrastructure require regular inspections and maintenance, tasks that are often dangerous and costly. Soft robots, with their ability to navigate tight spaces and interact gently with delicate equipment, could streamline these processes, reducing downtime and improving safety. “The potential for soft robotics in the energy sector is immense,” says Hasib. “These robots could revolutionize how we maintain and inspect underwater infrastructure, making these operations more efficient and cost-effective.”

However, the study also identifies critical challenges that need to be addressed. Material degradation, energy efficiency, and control in dynamic aquatic conditions remain significant hurdles. Addressing these challenges will require interdisciplinary approaches, combining expertise from materials science, robotics, and marine biology. “The future of underwater soft robotics lies in collaboration,” says Hasib. “By bringing together experts from different fields, we can develop robots that are not only more capable but also more adaptable to the complexities of underwater environments.”

As the field continues to evolve, the study serves as a valuable resource for researchers and professionals seeking to advance the technology and its applications. With its emphasis on cutting-edge soft actuator technologies and interdisciplinary applications, it paves the way for future developments that could transform how we interact with the underwater world. For the energy sector, this research offers a glimpse into a future where maintenance and inspections are safer, more efficient, and more cost-effective—thanks to the innovative world of soft robotics.