In the intricate world of underground construction, particularly in the energy sector, the precise calculation of jacking force for curved pipe installations is a critical yet challenging endeavor. A recent study published in *Engineering Reports* (translated from Chinese as “Engineering Reports”) by Juan Chen of Wuhan Yuchengqianli Construction Group Co. Ltd. in Wuhan, China, sheds new light on this complex issue, offering insights that could revolutionize the way engineers approach curved pipe jacking projects.

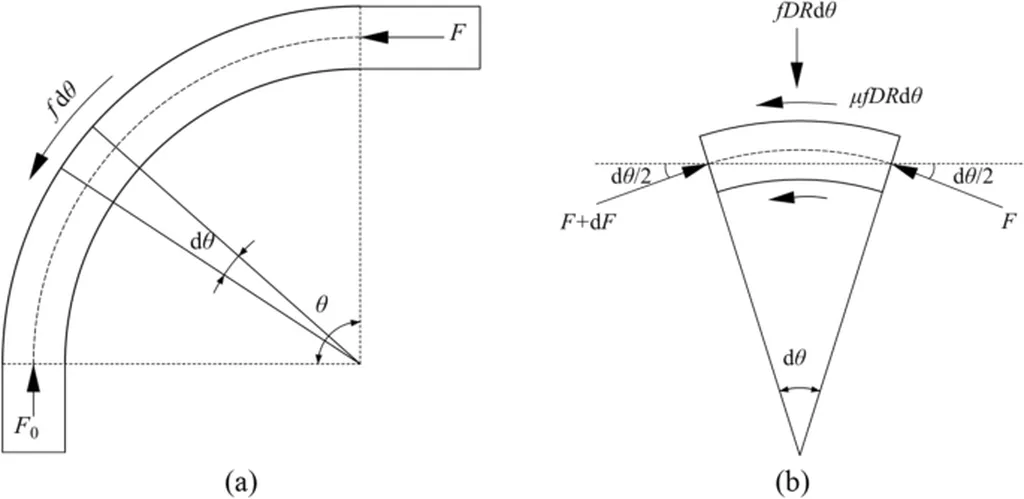

Jacking force, the driving force behind the installation of pipes underground, is a pivotal factor in ensuring the success and efficiency of such projects. However, the surrounding pipe frictional resistance, influenced by the dynamic interplay between the pipe, soil, and grouting slurry, has long been a source of uncertainty. Chen’s research delves into this very challenge, analyzing data from the Nanniwan curved pipe jacking project to evaluate the accuracy of commonly used formulas for calculating push force.

The findings are compelling. Chen discovered that the existing formulas, while widely applied, often yield significant discrepancies when compared to actual measurements. This inconsistency can lead to inefficiencies and potential risks in construction projects, particularly in the energy sector where precision is paramount.

To address this issue, Chen proposes a novel approach: segmenting the pipe-soil contact state according to the pipe-soil lubrication grouting conditions and then modeling the segmented calculation jacking force using ABAQUS simulation software. The results are promising. “The jacking force after segmentation is close to the measured value, which meets the construction and design requirements,” Chen explains. This method not only enhances accuracy but also ensures that projects are completed efficiently and safely.

The implications of this research are far-reaching. For the energy sector, where underground pipelines are a cornerstone of infrastructure, this new method could significantly improve the planning and execution of projects. By reducing uncertainties and enhancing precision, engineers can optimize resource allocation, minimize risks, and ultimately drive down costs.

As the construction industry continues to evolve, the need for accurate and reliable calculation methods becomes ever more critical. Chen’s research represents a significant step forward in this regard, offering a robust solution to a longstanding challenge. “This study provides a valuable tool for engineers and project managers, enabling them to make more informed decisions and achieve better outcomes,” Chen notes.

Looking ahead, the integration of advanced simulation software like ABAQUS into the planning and execution of curved pipe jacking projects could become a standard practice. This shift towards more sophisticated and precise methods is likely to shape the future of underground construction, driving innovation and efficiency in the energy sector and beyond.

In the words of Chen, “The future of curved pipe jacking lies in our ability to harness the power of data and simulation to overcome the complexities of the underground environment.” With this research, Chen has not only advanced our understanding of jacking force calculation but also paved the way for a new era of precision and efficiency in underground construction.