In the relentless pursuit of monitoring and maintaining advanced equipment in extreme environments, a breakthrough has emerged that could redefine the landscape of temperature sensing. Researchers, led by Yuyu Hou from the State Key Laboratory of Fluid Power and Mechatronic Systems at Zhejiang University, have developed a novel laser-induced wide-range thin-film temperature sensor that promises to simplify and enhance structural health monitoring, particularly in the energy sector.

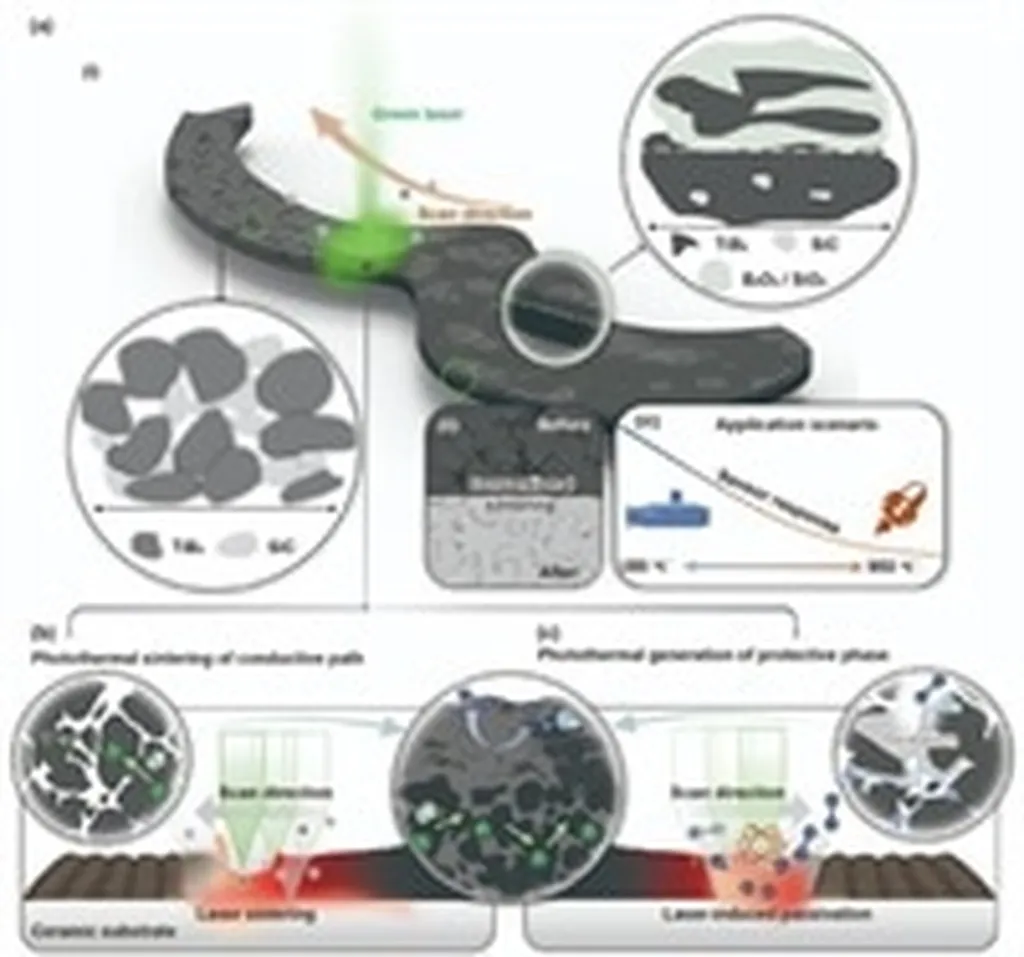

The innovation lies in the sensor’s ability to be fabricated in-situ, eliminating the need for complicated layer-by-layer molding and sintering processes typically required for such devices. “Our approach leverages the instantaneous thermal effect of laser irradiation to create crystalline conductive traces that respond to temperature variations,” explains Hou. “Simultaneously, it forms an amorphous antioxidative layer, negating the need for additional protective coatings.”

This dual functionality is a game-changer. The sensor can precisely track temperatures in real-time across an impressive range, from -50°C to 950°C, adhering to the Steinhart-Hart equation. Its durability is equally impressive, with only a 1.2% drift over 20 hours during long-term high-temperature tests, instant thermal shocks, frequent wearing, and severe vibrations.

The implications for the energy sector are profound. In industries where equipment operates in extreme environments—such as oil and gas, nuclear power, and renewable energy—the ability to accurately monitor temperature in real-time can significantly enhance safety, efficiency, and longevity of assets. “This technology could revolutionize structural health monitoring and fault diagnosis,” says Hou, “enabling predictive maintenance and reducing downtime.”

The sensor’s simplicity and effectiveness could also drive down costs, making advanced temperature monitoring more accessible. As the world grapples with the challenges of climate change and the push for cleaner energy, such innovations become increasingly vital.

Published in the *International Journal of Extreme Manufacturing* (translated as “International Journal of Extreme Manufacturing”), this research opens up new avenues for in-situ integration of temperature sensors in extreme environments. The potential for future developments is vast, with possibilities ranging from improved sensor networks to integrated smart materials that can self-monitor and self-repair.

As the energy sector continues to evolve, innovations like this will be crucial in meeting the demands of a changing world. The research by Hou and his team is a testament to the power of interdisciplinary collaboration and the potential of laser technology to transform industries.