In the quest to enhance the properties of aluminum alloys, researchers have been exploring innovative techniques that can refine microstructure and bolster mechanical strength. A recent study published in *Materials Research Express* (which translates to *Expressions of Materials Research*) has shed light on the significant role that tool rotational speed plays in friction stir processing (FSP) of AA5754 aluminum alloy. This research, led by Senthilnathan K. from the Department of Mechanical Engineering at Anna University in Chennai, India, offers promising insights for industries seeking to optimize material performance, particularly in the energy sector.

Friction stir processing, a derivative of friction stir welding, is gaining traction as a method to modify the microstructure of low-temperature alloys without melting them. This solid-state process mitigates issues related to solidification, making it an attractive option for enhancing material properties. Senthilnathan and his team focused on overlapping 6-mm-thick AA5754 aluminum alloy sheets to achieve a total thickness of 12 mm. Using a tapered-threaded high-speed steel (HSS) tool, they performed FSP at varying rotational speeds while keeping other parameters constant.

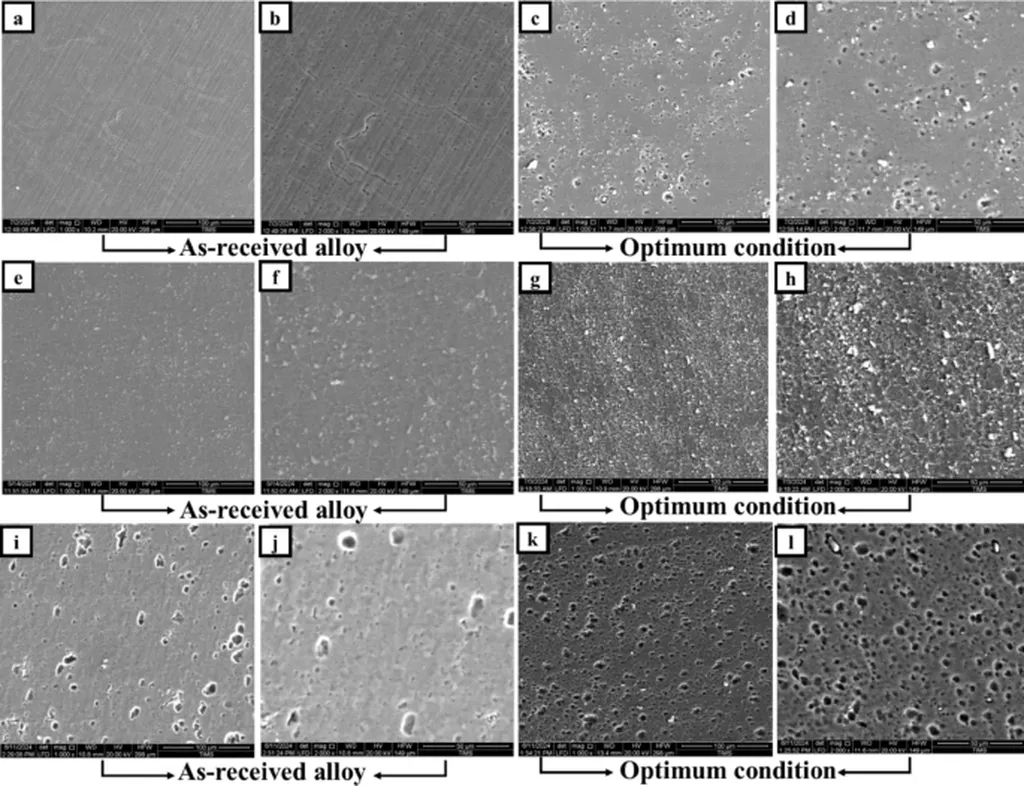

The study revealed that a rotational speed of 700 revolutions per minute (rpm) yielded a defect-free FSP region, likely due to optimal heat generation. “The tool’s rotational speed is crucial in heat generation, which in turn influences the microstructure and mechanical properties of the material,” explained Senthilnathan. At 700 rpm, the processed material exhibited a maximum tensile strength of 245 MPa, attributed to the formation of finer grains and more refined strengthening precipitates in the stir zone.

The implications of this research are far-reaching, particularly for the energy sector where lightweight, high-strength materials are in high demand. Aluminum alloys, known for their excellent strength-to-weight ratio, are widely used in applications ranging from power generation to renewable energy technologies. Enhancing their mechanical properties through optimized FSP techniques could lead to more efficient and durable components, ultimately reducing maintenance costs and improving overall performance.

As the energy sector continues to evolve, the need for advanced materials that can withstand extreme conditions becomes increasingly critical. This study highlights the potential of FSP to tailor the properties of aluminum alloys, paving the way for innovative solutions in material science. “Understanding the relationship between processing parameters and material properties is key to unlocking new possibilities in industrial applications,” added Senthilnathan.

The findings published in *Materials Research Express* underscore the importance of precise control over processing parameters to achieve desired material properties. As researchers continue to explore the capabilities of FSP, the energy sector stands to benefit from these advancements, driving progress towards more sustainable and efficient energy solutions.