In the world of steel production, precision and efficiency are paramount, and a recent study published in the journal *Materials Research Express* (translated to English as *Materials Research Express*) is shedding new light on how temperature fluctuations can impact the rolling process of DP590 steel. Led by Yu-Kun Zhang from the School of Metallurgy and Energy at North China University of Science and Technology, the research delves into the complexities of non-uniform temperature fields and their effects on multi-pass rough rolling, offering insights that could revolutionize the industry.

DP590 steel, known for its high strength and ductility, is a critical material in various industrial applications, including automotive manufacturing and construction. However, achieving consistent quality during production has been a persistent challenge. Zhang’s study employs advanced numerical simulation techniques to uncover the formation mechanisms of temperature field inhomogeneity during continuous casting and its subsequent impact on rolling processes.

The research utilizes a 2D continuous casting temperature field model developed in Abaqus, a powerful simulation software. The model parameters include a slab size of 1600 × 230 mm, a casting speed of 1.1 meters per minute, and a specific water volume of 1.99 liters per kilogram. This model reveals the thermal evolution during the cooling process, providing a detailed understanding of how temperature variations occur.

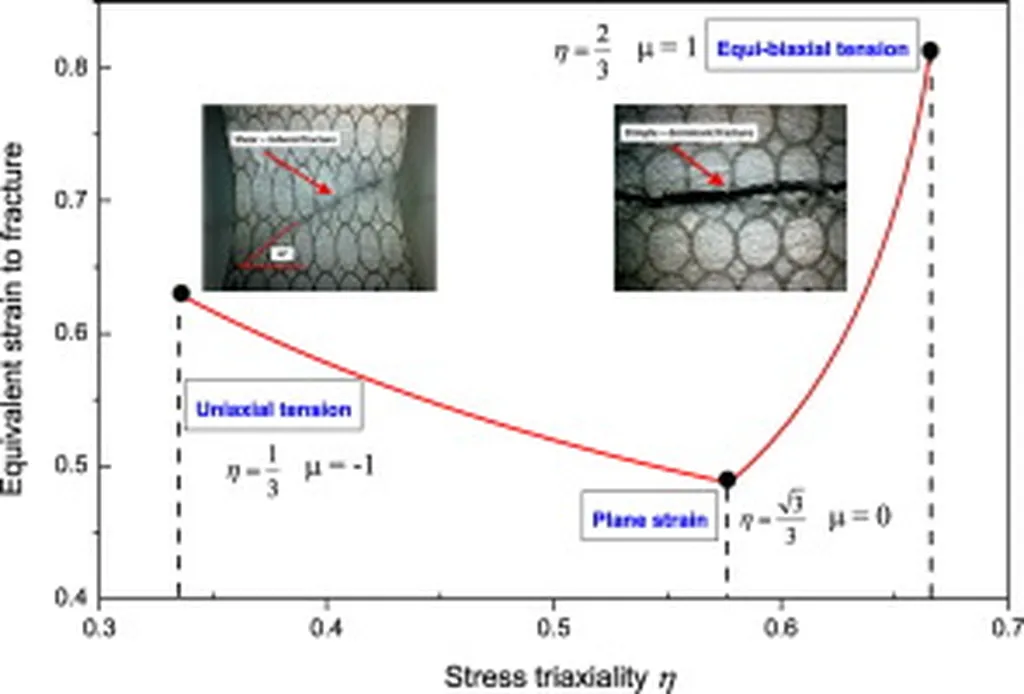

Building on this, a 3D heating-rolling model incorporates parameters such as a work roll radius of 500 mm and a speed of 6 radians per second. This model analyzes how temperature inhomogeneity affects rolling force and stress-strain distribution. The findings are striking: non-uniform temperature fields significantly exacerbate rolling force fluctuations. Specifically, the rolling force under 600 seconds of heating increases by approximately 15% to 20% compared to a uniform 1200°C temperature field. This temperature inconsistency also induces a stress gradient along the thickness direction, with a stress difference exceeding 20 MPa between the surface and core, and a non-uniform strain distribution, with a strain difference reaching 0.68.

However, the study also offers a solution. Extending the heating duration to 1200 seconds reduces the core-surface temperature difference to below 300°C, achieving stress-strain distribution uniformity comparable to isothermal conditions. “Optimized heating processes enhance deformation uniformity, resolving the conflict between low-energy production and product quality in low-speed casting scenarios,” Zhang explains. This breakthrough could have significant commercial implications for the energy sector, where efficient and high-quality steel production is crucial.

The research not only highlights the importance of temperature control in steel production but also paves the way for future developments in the field. By understanding and mitigating the effects of non-uniform temperature fields, manufacturers can improve product quality, reduce energy consumption, and enhance overall efficiency. As Zhang’s work demonstrates, the key to unlocking these benefits lies in advanced numerical simulation and a deep understanding of the underlying physical processes.

In an industry where every degree and every millimeter matters, this study is a significant step forward. It underscores the potential of cutting-edge research to drive innovation and shape the future of steel production. As the energy sector continues to evolve, the insights gained from this research could prove invaluable in meeting the demands of a rapidly changing world.