In the realm of advanced manufacturing, precision is paramount. Nowhere is this more evident than in the fabrication of high-aspect-ratio (HAR) thin walls, particularly those made from challenging materials like titanium alloys. A recent study led by Y. Li from the School of Medical Imaging at Qilu Medical University in China is shedding new light on how to achieve unprecedented accuracy in this delicate process, with potential ripple effects across industries, including energy.

Titanium alloys are prized for their strength-to-weight ratio and corrosion resistance, making them ideal for aerospace, medical, and energy applications. However, their use in creating HAR thin walls—structures with a height-to-width ratio of 10:1 or more—has been hampered by dimensional inaccuracies. Li’s research, published in the journal *Mechanical Sciences* (which translates to *Mechanical Sciences* in English), aims to change that.

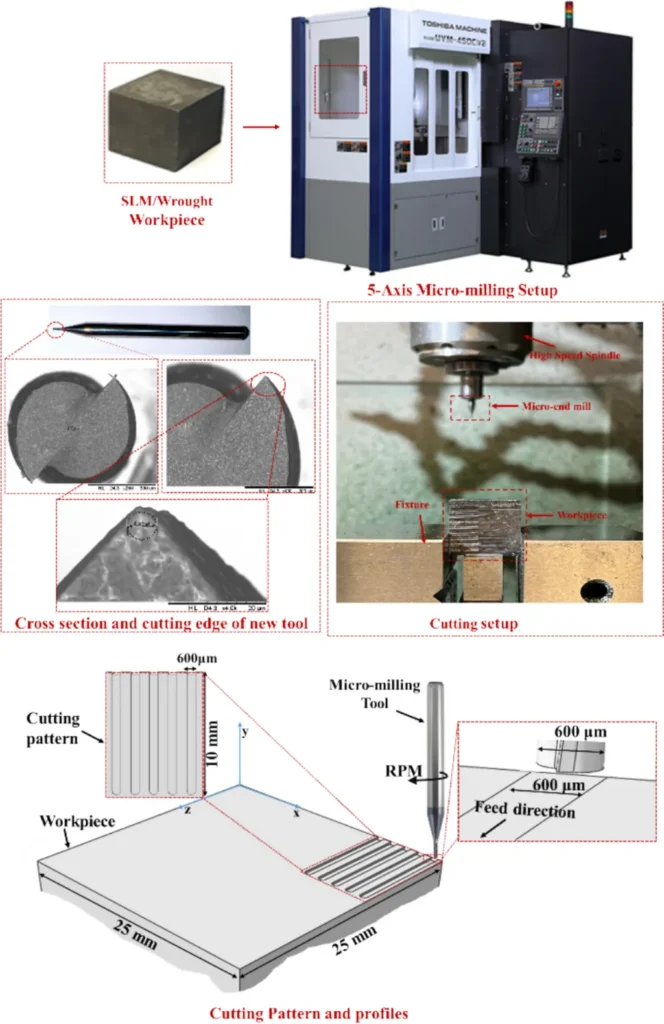

The study systematically investigates the micromilling characteristics of titanium alloy Ti-6Al-4V, a commonly used grade in industrial applications. “We conducted micromilling experiments using straight edge polycrystalline diamond (PCD) end mills with different rake angles,” Li explains. “By comparing the effects of tool shape on cutting force, temperature, dimensional error, tool wear, and surface morphology, we identified the optimal cutting edge shape for this delicate task.”

But Li’s team didn’t stop at identifying the best tool shape. They went a step further by developing a deformation prediction model for micromilling titanium alloy. This model is designed to compensate for thin wall deformations in real-time, a critical advancement for industries requiring high-precision components.

“Our model can be applied to online compensation of thin wall deformations,” Li says. “This means that as the material is being cut, the system can adjust to minimize errors, leading to a final product that is far more accurate than what was previously possible.”

The results speak for themselves. Using this predictive model, Li’s team successfully fabricated a thin wall with an aspect ratio of 10:1 and a thickness of just 60 micrometers. The relative dimensional error was reduced from 16.5% to a mere 3.9%, a significant improvement that could have profound implications for industries relying on high-precision components.

For the energy sector, this research could be a game-changer. From turbine blades to nuclear components, the ability to create high-precision, HAR thin walls from titanium alloys could lead to more efficient, durable, and reliable energy infrastructure. “This research provides a method for guiding the thin wall machining of other difficult-to-machine materials,” Li notes, hinting at the broader applications of this technology.

As industries continue to push the boundaries of what’s possible, research like Li’s serves as a reminder that precision is not just a goal—it’s a necessity. And with advancements like this, the future of manufacturing looks sharper than ever.