In the bustling world of construction, time is money, and efficiency is king. Tower cranes, the towering titans of building sites, are crucial for meeting high-performance demands. However, one persistent challenge has been the pendulum oscillations of loads, which can slow down operations and increase safety risks. A recent study published in ‘Machinery & Energetics’ (translated as ‘Machinery and Energy’) tackles this very issue, offering a promising solution that could revolutionize the way tower cranes operate.

Yu. Romasevych, the lead author of the study, has delved into the dynamics of tower crane systems to optimize the acceleration of the slewing mechanism. “The goal was to eliminate pendulum oscillations in the shortest possible time,” Romasevych explains. By doing so, the efficiency and safety of crane operations could see significant improvements.

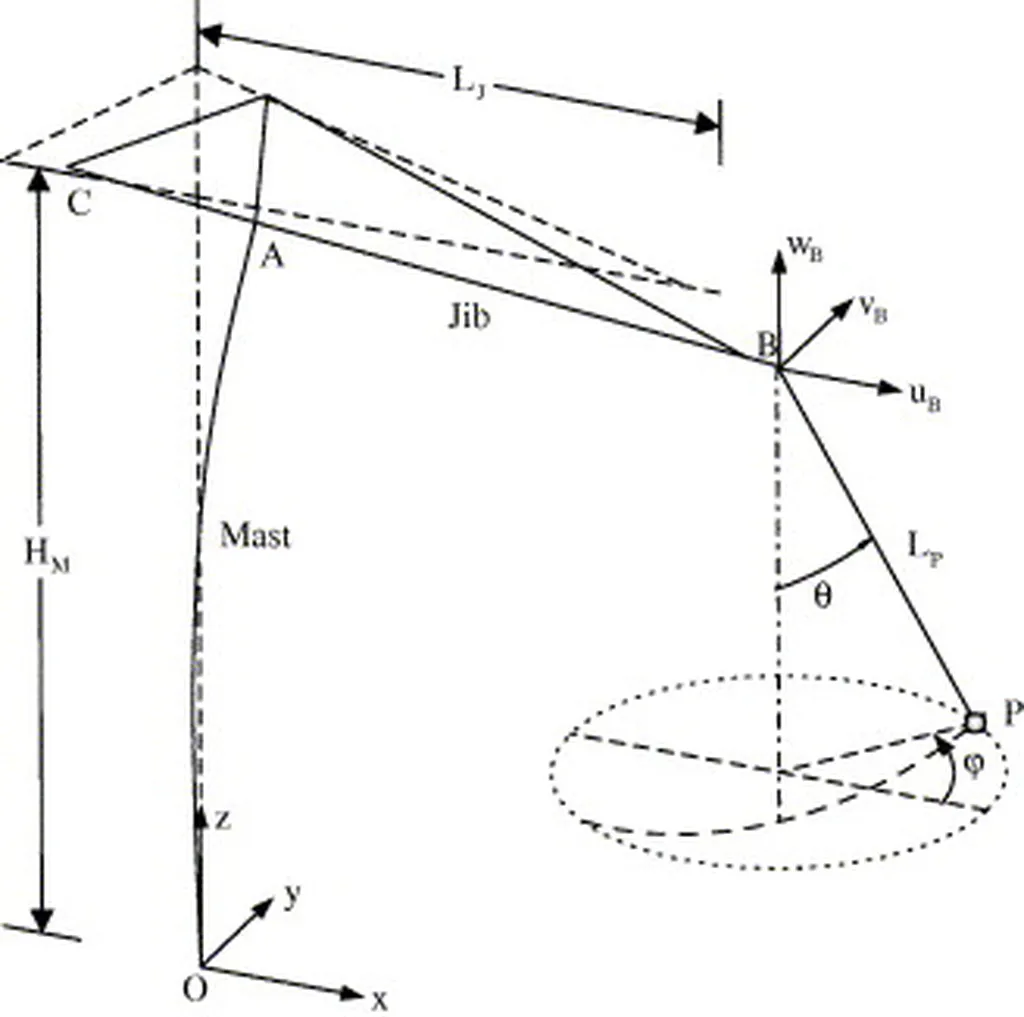

The research presents a dynamic system model of the tower crane, introducing boundary conditions, optimization criteria, and a torque constraint. The problem was then reduced to unconstrained optimization of a nonlinear function, a complex task that was solved using the VCT-PSO optimization algorithm. This algorithm was employed to find solutions under varying conditions, including different load masses, suspension lengths, and boom extension ranges.

One of the most intriguing aspects of this study is the use of artificial neural networks (ANNs) to predict control switching moments. Romasevych and his team used a feedforward neural network with three inputs (load mass, boom extension range, and suspension length) and three outputs (control switching moments). The network was trained using the ADAM method, and the results were impressive. “The high quality of the approximation of the solution surface of the problem using the artificial neural network was established,” Romasevych notes.

The implications of this research for the construction and energy sectors are substantial. Efficient crane operations can lead to faster project completion times, reduced labor costs, and improved safety. In the energy sector, where large-scale construction projects are common, these advancements could translate to significant cost savings and improved project outcomes.

Moreover, the use of ANNs in this context opens up new avenues for research and development. As Romasevych points out, “The analysis of the system motion dynamics under optimal control demonstrated that the system motion indicators were least affected by the mass of the load and most affected by the length of the flexible suspension.” This insight could guide future designs and optimizations of tower cranes.

The study published in ‘Machinery & Energetics’ not only addresses a longstanding challenge in the construction industry but also paves the way for future innovations. As the field continues to evolve, the integration of advanced technologies like ANNs could become a standard practice, driving efficiency and safety to new heights. For professionals in the construction and energy sectors, this research offers a glimpse into the future of crane operations and the potential benefits that lie ahead.