In a groundbreaking development for the textile industry, researchers have introduced a novel method to distinguish between cashmere and wool fibers using near-infrared spectroscopy (NIR), a technique that is both fast and non-destructive. The study, led by Jihong Lian from the School of Electronics and Information at Xi’an Polytechnic University in Shaanxi, China, presents a model that significantly enhances the accuracy of fiber prediction, addressing a longstanding challenge in the field.

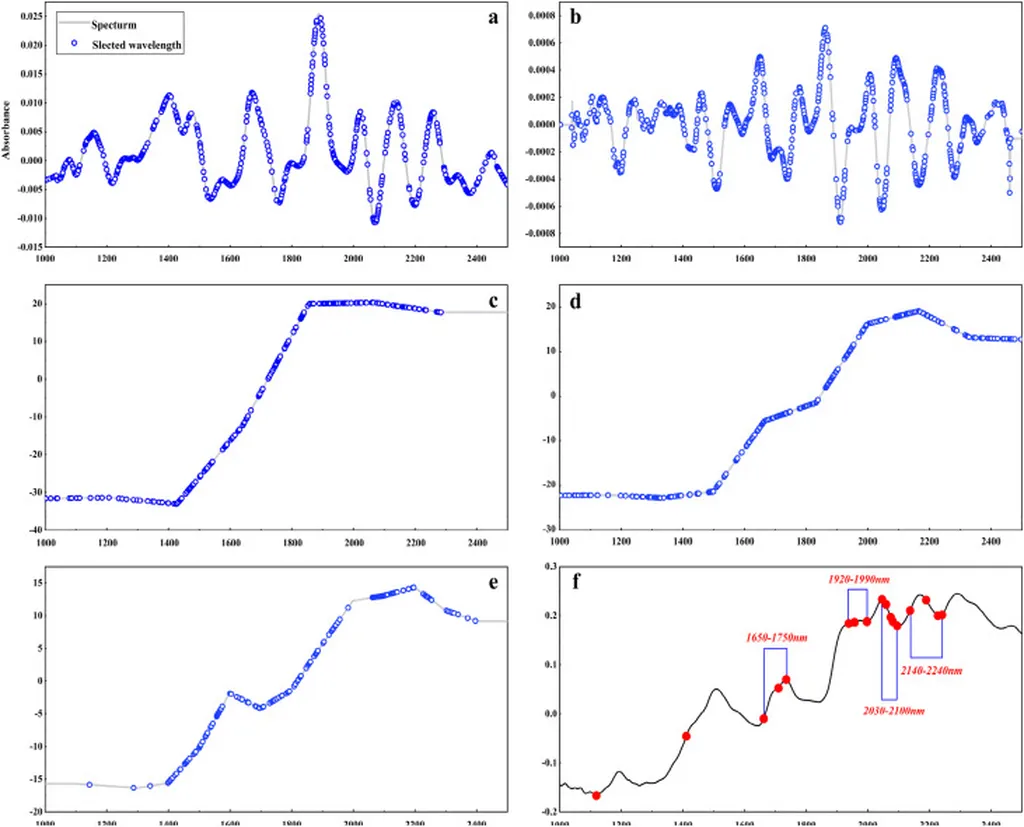

The proposed model combines Markov transition field (MTF) with an improved version of the YOLOv8 algorithm, a deep learning approach known for its object detection capabilities. By calculating the Markov transition matrix of local NIR data and expanding it into a MTF, the researchers have effectively enhanced the model’s ability to focus on local frequency bands and peaks. “This method allows us to capture the subtle differences between cashmere and wool fibers that were previously difficult to distinguish,” Lian explained.

The improved YOLOv8 model replaces its backbone network with a hierarchical visual transformer using displacement windows, further boosting its attention to critical spectral features. To prevent overfitting, dropout layers were added to the Swin Transformer (ST) component. The model’s performance was rigorously tested against other algorithms, including KNN, decision trees, random forests, AlexNet, VGG16, GoogLeNet, ResNet50, and the original YOLOv8. The results were impressive, with the new model achieving an average prediction accuracy of 97.01%.

The implications of this research are substantial for the textile industry. Accurate and rapid identification of cashmere and wool fibers can streamline quality control processes, reduce costs, and enhance product authenticity. As Lian noted, “This technology provides a new approach for qualitative analysis in near-infrared spectroscopy, offering a rapid and non-destructive method for fiber prediction.”

The study, published in the Journal of Engineered Fibers and Fabrics (translated to English as “Journal of Engineered Fibers and Fabrics”), represents a significant advancement in the application of machine learning and spectroscopy in the textile sector. As the industry continues to evolve, such innovations are likely to play a crucial role in shaping future developments, ensuring higher standards of quality and efficiency.

This research not only highlights the potential of combining advanced algorithms with spectroscopic techniques but also underscores the importance of interdisciplinary collaboration in driving technological progress. As the textile industry embraces these advancements, the benefits will extend beyond the sector, influencing related fields and contributing to a more sustainable and efficient industrial landscape.