In a groundbreaking development poised to revolutionize the food packaging industry, researchers have created an antibacterial polymer composite using an innovative technique that combines atmospheric pressure plasma jet (APPJ) treatment and zinc oxide nanoparticles (ZnO NPs). This novel approach, detailed in a study led by Rafaela Radičić from the Centre for Advanced Laser Techniques at the Institute of Physics in Zagreb, Croatia, could significantly enhance food safety and extend shelf life, with potential ripple effects across the energy sector.

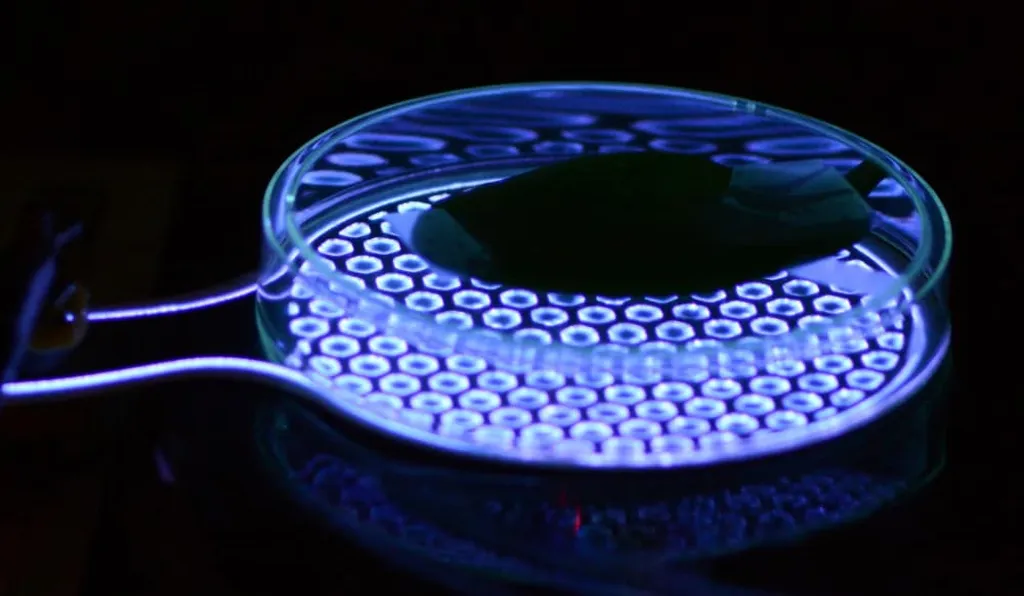

The research, published in the journal ‘Applied Surface Science Advances’ (translated as ‘Advanced Studies in Applied Surface Science’), introduces a method for synthesizing PET/ZnO composites with varying ZnO concentrations. The process involves pre-treating polyethylene terephthalate (PET) with an APPJ, followed by drop coating with a ZnO colloidal solution synthesized via pulsed laser ablation in water. This ensures the production of clean nanoparticles. An additional APPJ treatment firmly embeds the NPs into the ripples created on the PET surface during the initial plasma treatment.

Radičić explains, “The key to our method lies in the dual APPJ treatment. Not only does it create a textured surface for better NP adhesion, but it also ensures that the nanoparticles are tightly incorporated, making the composite suitable for direct food contact.”

The PET/ZnO composites were subjected to rigorous testing to confirm the tight incorporation of NPs and their suitability for food packaging. Techniques such as UV–Vis spectroscopy, water contact angle measurements, FTIR, SEM, AFM, XPS, SIMS, and ICP-MS were employed to characterize the ZnO NPs and the PET/ZnO composites. The results were promising, with the highest ZnO concentration leading to a 29% increase in the UPF value, indicating improved UV protection.

Moreover, the study found that incorporating ZnO NPs at concentrations of 200 and 500 µL helped reinforce PET’s elasticity, which had initially been reduced by the APPJ treatment. This finding is crucial for maintaining the structural integrity of packaging materials.

Given the potential application of the PET/ZnO composite in food packaging, antimicrobial activity tests were conducted against Gram-negative Escherichia coli and Gram-positive Staphylococcus aureus bacteria. The results were impressive, with the highest ZnO NP concentration achieving nearly 100% antibacterial efficiency for both bacterial strains.

The implications of this research extend beyond the food packaging industry. The enhanced UV protection and antibacterial properties of the PET/ZnO composite could also benefit the energy sector, particularly in the development of more durable and efficient solar panels and other energy-related applications.

Radičić envisions a future where this technology could be widely adopted. “Our method offers a scalable and efficient way to produce antibacterial and UV-protective materials. We believe that this could pave the way for safer food packaging and more robust materials in various industries.”

As the world continues to grapple with food safety and sustainability challenges, this innovative approach to creating antibacterial polymer composites offers a glimmer of hope. The research by Radičić and her team not only advances our understanding of material science but also opens up new avenues for commercial applications, potentially shaping the future of the energy sector and beyond.