In a breakthrough that could reshape the energy sector, researchers have developed a novel strategy to enhance the performance of high-entropy alloys (HEAs) in electrocatalysis, particularly for the oxygen evolution reaction (OER). This process is crucial for technologies like water splitting, which is essential for producing green hydrogen, a clean energy carrier. The study, led by Jiangfei Wang from Jinchang Bengxinwangda Environmental Protection Technology Co., Ltd, was recently published in *Materials Letters: X*, which translates to *Materials Letters: New*.

High-entropy alloys, known for their unique properties arising from the combination of multiple elements, have garnered significant attention in recent years. However, their full potential in electrocatalysis has remained largely untapped. Wang and his team have now demonstrated a method to fabricate porous FeCoNiAlMo HEAs with enhanced OER activity using electrochemical dealloying in a choline chloride-urea deep eutectic solvent.

The process involves corroding the alloy preferentially along the face-centered cubic (FCC) phase, leaving behind a three-dimensional porous structure composed mainly of the body-centered cubic (BCC) phase. This unique morphology significantly lowers the energy barrier during the hydrolysis process, making the material highly efficient for OER. “The porous structure synergistically reduces the energy barrier, giving the material a significant advantage in the oxygen evolution reaction process,” Wang explained.

The treated alloy exhibited an overpotential of just 312 mV at a current density of 10 mA cm−2, outperforming commercial RuO2-IrO2 catalysts. Moreover, the material demonstrated lower resistance and higher charge transfer efficiency, making it a promising candidate for industrial applications.

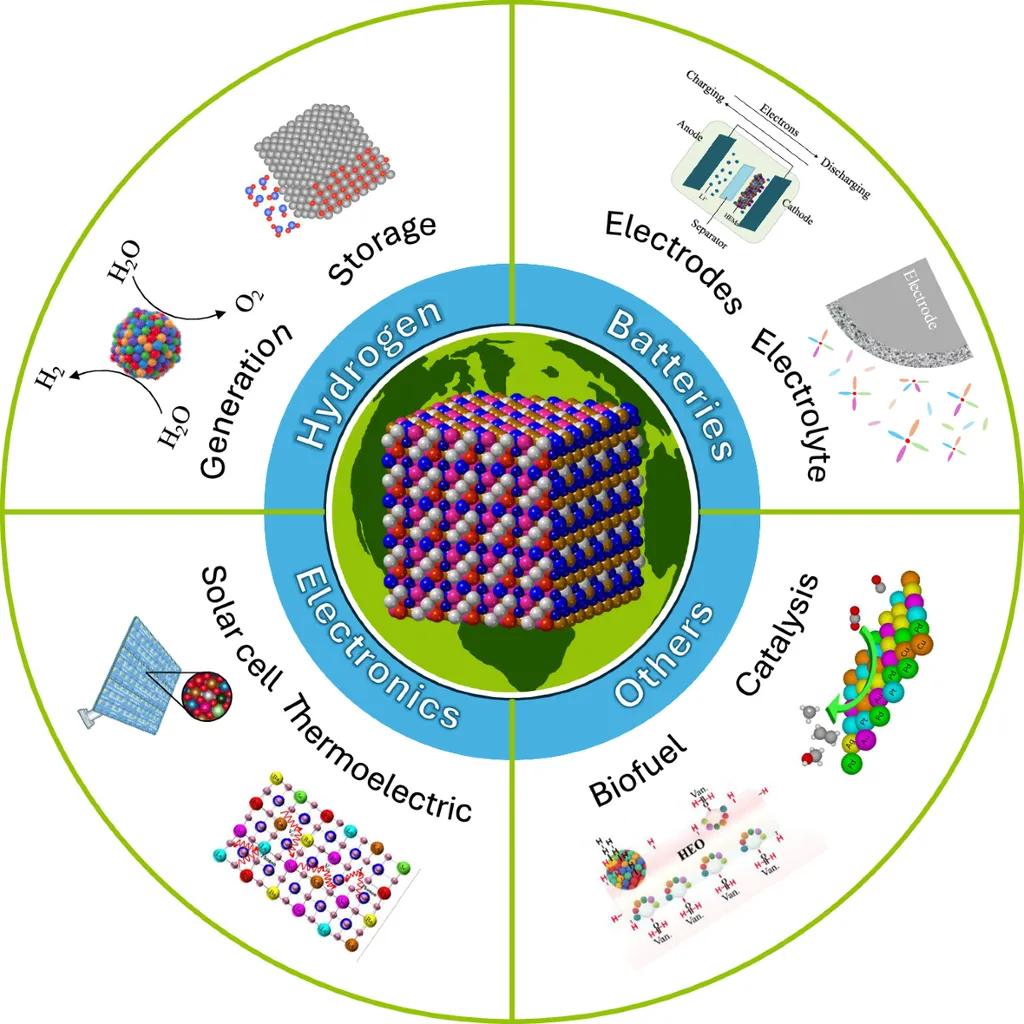

The implications of this research are far-reaching. As the world shifts towards cleaner energy solutions, the demand for efficient and cost-effective catalysts is on the rise. The enhanced performance of these porous HEAs could pave the way for more efficient water splitting technologies, contributing to the production of green hydrogen. “This strategy not only improves the catalytic performance but also provides a new direction for the design and fabrication of high-entropy alloys for various applications,” Wang added.

The study published in *Materials Letters: X* opens new avenues for research and development in the field of electrocatalysis. By leveraging the unique properties of high-entropy alloys and advanced fabrication techniques, researchers can continue to push the boundaries of what is possible in clean energy technologies. As the energy sector evolves, innovations like these will be crucial in meeting global sustainability goals and transitioning to a greener future.