In a groundbreaking development poised to reshape sustainable construction materials, researchers have unveiled a novel hybrid fiber-reinforced alkali-activated concrete (AAHFRC) that significantly enhances compressive strength and impact resistance. This innovation, spearheaded by Tejeswara Rao Maganti from the Department of Civil Engineering at Jawaharlal Nehru Technological University Kakinada (JNTUK) in India, promises to revolutionize the energy sector by offering a durable, high-performance alternative to traditional concrete.

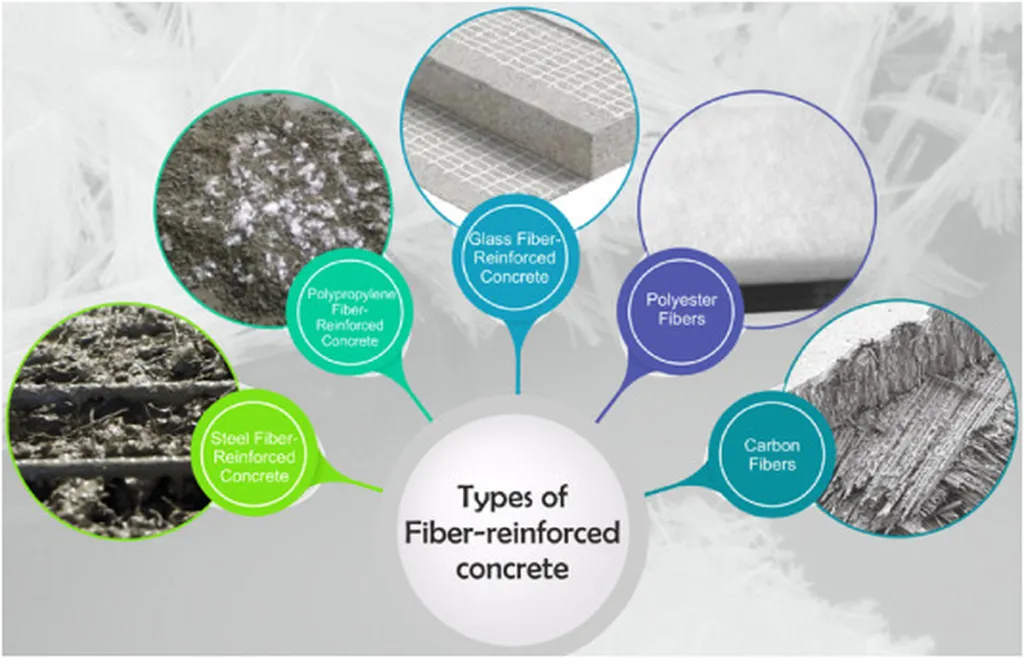

The study, published in the open-access journal Composites Part C: Open Access (translated as “Composites Part C: Open Access” in English), explores the potential of AAHFRC through a specialized ternary mix of fly ash (FA), ground granulated blast furnace slag (GGBS), and silica fume (SF) in a 35:50:15 ratio. The incorporation of hybrid fibers—steel, polypropylene, and glass—further amplifies the material’s performance. “The synergy between these fibers is truly remarkable,” Maganti explains. “It’s not just about improving one aspect; it’s about creating a material that excels in multiple areas, making it ideal for advanced construction applications.”

The experimental results are nothing short of impressive. The AAHFRC demonstrated a 63% increase in compressive strength, with the highest value recorded at 106.38 MPa for the ASG2.0 hybrid mix. Impact resistance also saw significant improvements, with the hybrid fiber mixes outperforming mono-fiber mixes and achieving the highest fracture impact energy (Ef) of 56 kN-m. The synergy factor further validated the effectiveness of hybrid systems, with the ASG2.0 mix attaining a synergy index of 1.37, surpassing mono-fiber mixes.

To complement the experimental findings, the research team conducted statistical Weibull analysis and finite element analysis (FEA) using ANSYS. The Weibull analysis revealed strong reliability, with an R-squared value of 0.989, indicating high consistency in impact resistance performance. The FEA verified improved stress distribution, reduced deformation, and a strong correlation between experimental and simulated results, with a difference of not more than 5%.

The implications for the energy sector are profound. As the demand for sustainable and durable construction materials grows, AAHFRC offers a promising solution. Its enhanced properties make it suitable for a wide range of applications, from wind turbine foundations to offshore structures, where impact resistance and compressive strength are critical.

“This research is a game-changer,” says Maganti. “It not only advances our understanding of hybrid fiber-reinforced concrete but also paves the way for more sustainable and resilient infrastructure in the energy sector.”

As the construction industry continues to evolve, the development of AAHFRC highlights the potential of innovative materials to shape the future of sustainable construction. With its impressive performance metrics and environmental benefits, AAHFRC is poised to become a cornerstone of advanced construction applications, driving progress in the energy sector and beyond.