In the quest to enhance the resilience and efficiency of construction materials, a groundbreaking study has emerged from the pages of *Jianzhu Gangjiegou Jinzhan*, a leading journal in the field of structural engineering. The research, led by Xu Ben from an undisclosed institution, delves into the performance of prefabricated steel energy-dissipating supports, specifically focusing on the impact of different hole shapes on their seismic performance.

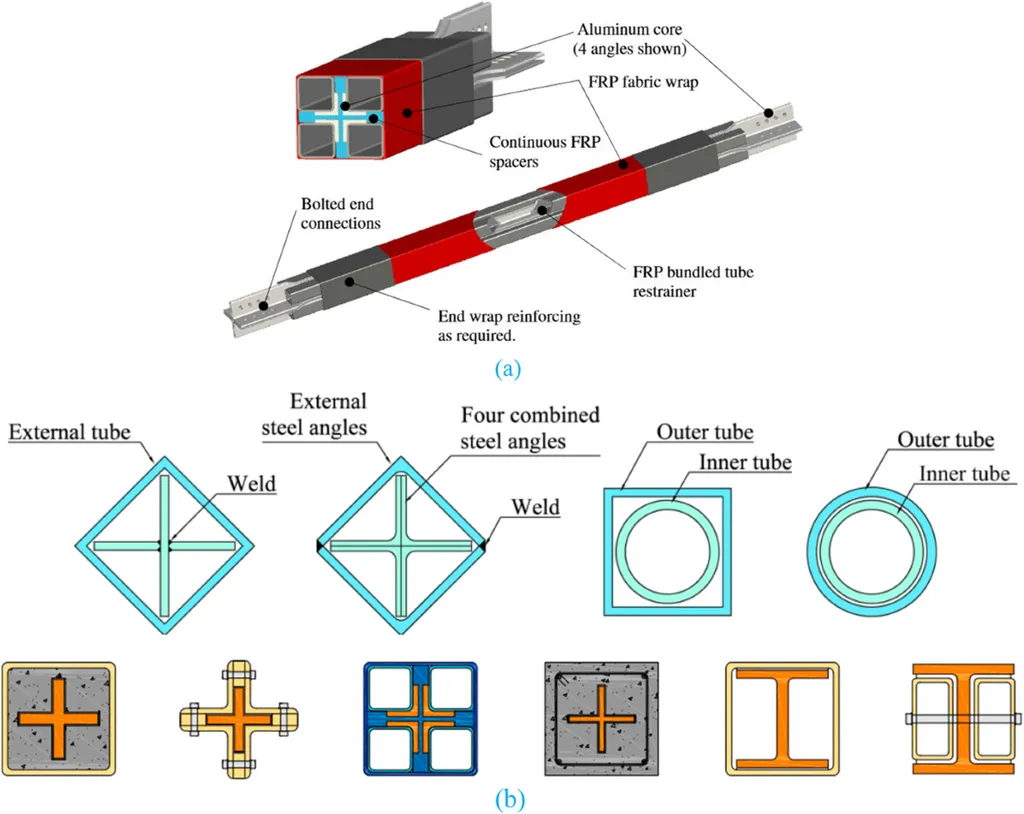

The study introduces a novel type of energy-dissipating support, known as the “prefabricated web-opened steel energy-dissipating support.” This innovative design features a central support brace flanked by web-opened steel sections, connected via bolts. The primary aim of this configuration is to prevent the central brace from buckling under pressure, thereby enhancing the overall stability and performance of the structure.

To investigate the seismic performance of these supports, Xu Ben and his team designed three test specimens with varying hole shapes—elliptical, circular, and rhombic. These specimens underwent low-cycle repetitive loading tests, simulating seismic conditions. The results were compelling. “The elliptical hole-shaped specimen exhibited the strongest energy dissipation capacity, while the rhombic hole-shaped specimen demonstrated the highest load-bearing capacity,” Xu Ben explained. This finding suggests that the shape of the holes in the web-opened steel sections plays a crucial role in determining the support’s performance under seismic conditions.

The study also revealed that reducing the aspect ratio of the web-opened steel sections significantly improved the load-bearing capacity and energy dissipation capacity of the supports. However, reducing the thickness-to-width ratio of the web-opened steel sections did not have a noticeable impact on the energy dissipation capacity.

The implications of this research are profound for the construction and energy sectors. As structures become more complex and the demand for energy efficiency grows, the need for innovative, resilient materials becomes ever more critical. The findings of this study could pave the way for the development of more efficient and resilient construction materials, ultimately contributing to safer and more sustainable buildings.

Moreover, the use of prefabricated components in construction can significantly reduce on-site labor and construction time, leading to cost savings and increased efficiency. This research could therefore have a significant impact on the commercial viability of construction projects, particularly in the energy sector where large-scale, complex structures are common.

As the construction industry continues to evolve, the insights gained from this research could shape the future of structural engineering. By understanding the impact of hole shapes on the performance of energy-dissipating supports, engineers and architects can design more resilient and efficient structures, ultimately contributing to a safer and more sustainable built environment.

In the words of Xu Ben, “This research not only advances our understanding of the seismic performance of prefabricated steel energy-dissipating supports but also opens up new possibilities for the design and construction of resilient and sustainable structures.” As the industry continues to grapple with the challenges of climate change and increasing urbanization, such innovations are more important than ever.