In the heart of Moscow, researchers are stirring up a revolution in construction materials that could have significant ripples across the energy sector. Svetlana V. Samchenko, a leading scientist at the National Research Moscow State University of Civil Engineering, has been exploring the potential of zeolite suspensions in cement systems, and her findings could reshape the way we think about building materials.

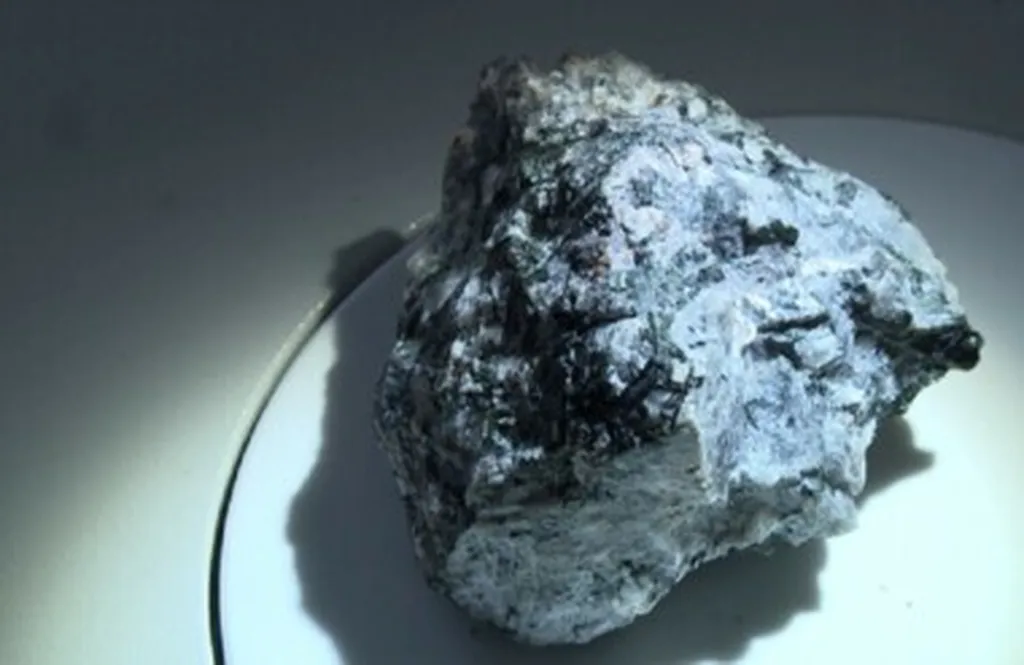

Zeolites, a group of hydrated aluminosilicate minerals, are known for their exceptional ion-exchange, sorption, and catalytic properties. But what makes Samchenko’s research particularly exciting is her focus on the stability of zeolite suspensions in cement mixtures. “The key to improving the physical and mechanical properties of cement lies in the uniform distribution of submicron particles within the composite,” Samchenko explains. Her study, published in the journal ‘Нанотехнологии в строительстве’ (Nanotechnology in Construction), delves into the intricacies of achieving this uniformity.

Samchenko and her team prepared zeolite suspensions with concentrations ranging from 10 to 50 grams per liter. They experimented with different dispersion media—water and water-polymer mixtures—and various treatment methods, including mechanical stirring and ultrasonic dispersion. The results were striking. Suspensions treated with both ultrasonic dispersion and a plasticizer proved to be the most stable. “The sedimentation velocity of suspension particles was significantly reduced, indicating a high degree of stability,” Samchenko notes.

But the real game-changer was the impact on the strength of the cement. When an ultrasonic-stabilized aqueous-polymer zeolite suspension was introduced into the cement composition, the initial and grade strength increased by 3.3 times and 51%, respectively. This enhancement in strength is not just a minor improvement; it’s a significant leap that could have profound implications for the construction and energy sectors.

Imagine buildings that are not only stronger but also more durable and energy-efficient. The uniform distribution of zeolite particles in the cement matrix acts as a substrate for the nucleation and growth of crystal hydrate phases, intensifying the hydration process and forming a dense, strong structure. This could lead to buildings that require less maintenance and have a longer lifespan, ultimately reducing the environmental impact and energy consumption associated with construction and repair.

The energy sector, in particular, stands to benefit from these advancements. Stronger, more durable materials can lead to more efficient and resilient energy infrastructure. From wind turbines to nuclear power plants, the demand for high-performance materials is ever-growing. Samchenko’s research could provide the foundation for developing these materials, making them more robust and reliable.

The commercial impacts of this research are vast. Construction companies could see significant cost savings due to reduced maintenance and increased durability of structures. The energy sector could benefit from more efficient and resilient infrastructure, leading to lower operational costs and improved performance. Moreover, the environmental benefits of using more durable and energy-efficient materials cannot be overstated.

As we look to the future, the potential applications of zeolite suspensions in cement systems are vast. Samchenko’s research opens up new avenues for exploration, paving the way for innovative solutions in the construction and energy sectors. “The feasibility of considering zeolites as components of composite materials is a promising direction in solving multifaceted problems in the construction industry,” she concludes.

In a world where sustainability and efficiency are paramount, Samchenko’s work offers a glimpse into a future where our buildings and infrastructure are not only stronger but also more environmentally friendly. The journey towards this future starts with a simple yet profound question: How can we make our materials better? And in Moscow, researchers are finding answers that could change the game.