In the quest for sustainable and efficient vehicle manufacturing and repair, researchers have turned their attention to the often-overlooked process of debonding structurally bonded components. A recent study, led by Alex Jordan from Paderborn University’s Laboratory for Material and Joining Technology, has shed light on the ecological and economic aspects of two debonding methods, potentially reshaping the automotive repair and recycling landscape.

The study, published in the *Journal of Advanced Joining Processes* (translated as *Journal of Advanced Connection Technologies*), compares the established hot-air debonding process with a novel cryogenic cold process using liquid nitrogen (LN2). The findings reveal a significant reduction in carbon footprint for the cryogenic method, with a notable 40% decrease compared to the hot-air process. This reduction is primarily attributed to the shorter process time and more efficient heat transfer of the LN2 method.

“The cryogenic method not only performs better ecologically but also shows promise for repair- and recycling-oriented adhesive separation in structural vehicle applications,” said Alex Jordan, lead author of the study. The research involved experimental investigations on a component-representative triple-sheet structure, simulating common automotive flange joints. Temperature profiles were recorded using spatially distributed thermocouples, and the mechanical integrity of the remaining adhesive joint was evaluated through Mode I testing of L-shaped specimens.

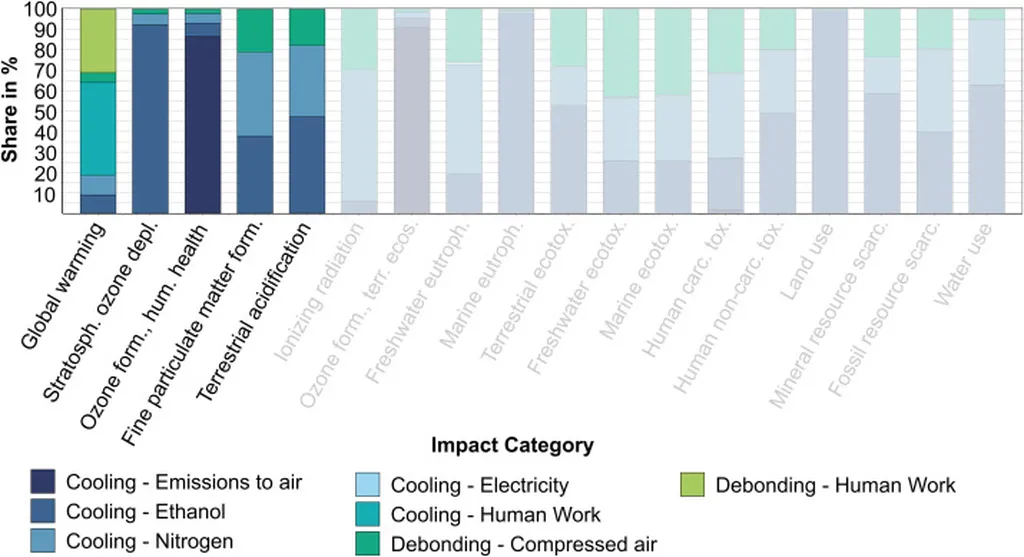

The study’s Life Cycle Assessment (LCA) according to DIN EN ISO 14,040 revealed that while the hot-air method’s impact is mainly driven by electrical energy use, the cold method’s impact stems from cryogenic media consumption. Despite certain disadvantages in specific impact categories, the LN2-based process exhibits a superior overall ecological performance.

The implications for the automotive industry are substantial. As vehicle manufacturers and repair shops increasingly prioritize sustainability, the cryogenic debonding method could become a standard practice. This shift could lead to more efficient repair processes, reduced environmental impact, and significant cost savings in the long run.

“The findings of this study highlight the importance of considering both ecological and economic factors in the development of new technologies,” added Jordan. “The cryogenic debonding method represents a step forward in achieving sustainable and efficient vehicle manufacturing and repair.”

As the automotive industry continues to evolve, the adoption of sustainable practices like the cryogenic debonding method could set new benchmarks for environmental responsibility and economic efficiency. This research not only advances our understanding of debonding processes but also paves the way for innovative solutions that benefit both the industry and the planet.