In the relentless pursuit of safer and more efficient energy infrastructure, a recent study has shed light on the often-overlooked role of thermal oxide films in the stress corrosion cracking (SCC) susceptibility of stainless steel welds. This research, led by Laura de Lima e Silva from CIRIMAT at the University of Toulouse and CETIM in Nantes, France, could have significant implications for the energy sector, particularly in environments where chloride-containing media are prevalent.

The study, published in the Journal of Advanced Joining Processes (known in English as the Journal of Advanced Welding Techniques), focused on 316L austenitic stainless steel (ASS) welded joints, a material commonly used in various industrial applications due to its excellent corrosion resistance. However, when exposed to chloride-containing environments, these welds can suffer from stress corrosion cracking, a phenomenon that can compromise the integrity of critical components.

De Lima e Silva and her team investigated the effect of thermal oxide films—formed during the welding process—on the SCC susceptibility of these welds. They compared the behavior of non-polished welds, covered by a thermal oxide film, with polished welds, which have a native oxide film. The findings were revealing.

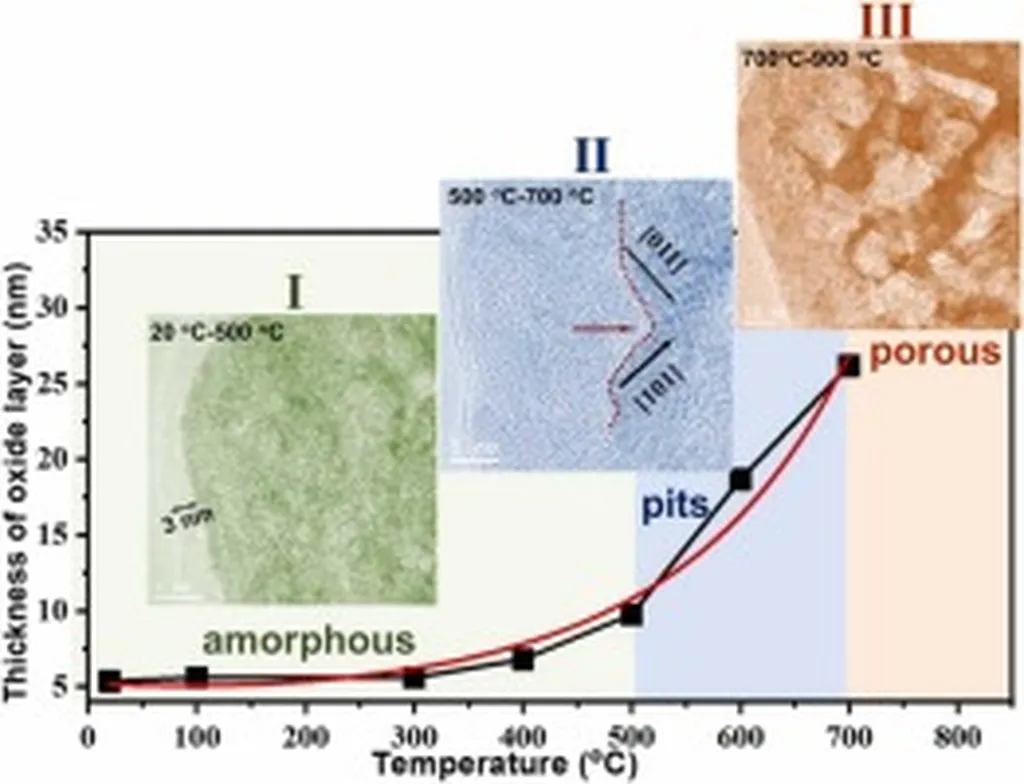

“The thermal oxide film presented a bi-layer structure similar to that of the native oxide film, but the ratio of iron to chromium in the outer layer of the thermal oxide film was higher,” explained de Lima e Silva. This higher iron content, coupled with the increased thickness and porosity of the thermal oxide film, led to a degradation in the corrosion behavior of the non-polished welds.

Moreover, the study found that the thermal oxide film’s properties influenced the crack propagation mode during SCC tests. While both polished and non-polished samples showed preferential crack formation in the heat-affected zone (HAZ), the non-polished samples exhibited a shift from intergranular to transgranular crack propagation. This change was particularly pronounced near the fusion line, where the thermal oxide was more porous and richer in iron.

“The defective structure of the thermal oxide film was associated with a degradation in the corrosion behavior of the non-polished weld,” de Lima e Silva noted. “Furthermore, crack propagation was promoted, with cracks extending across multiple grains, in the HAZ of the non-polished sample near the fusion line.”

These findings underscore the critical role of thermal oxide properties in the corrosion behavior and SCC susceptibility of 316L welds. For the energy sector, this research could lead to improved welding techniques and post-weld treatments that enhance the corrosion resistance of stainless steel components, ultimately reducing maintenance costs and improving safety.

As the energy industry continues to push the boundaries of efficiency and reliability, understanding and mitigating the factors that contribute to stress corrosion cracking will be paramount. This study, published in the Journal of Advanced Joining Processes, provides a significant step forward in that endeavor, offering valuable insights that could shape future developments in the field.