In the world of power transmission, every degree of efficiency counts, and a recent study by M. E. Vysotski of the Belarusian National Technical University is shedding new light on how to optimize the performance of power cable lines. Published in the journal “Proceedings of Higher Educational Institutions and Energy Unions of the CIS: Energy” (translated from Russian), Vysotski’s research tackles a critical issue: the trade-off between using more expensive, thermally conductive backfill materials in cable trenches and the long-term economic benefits they might provide.

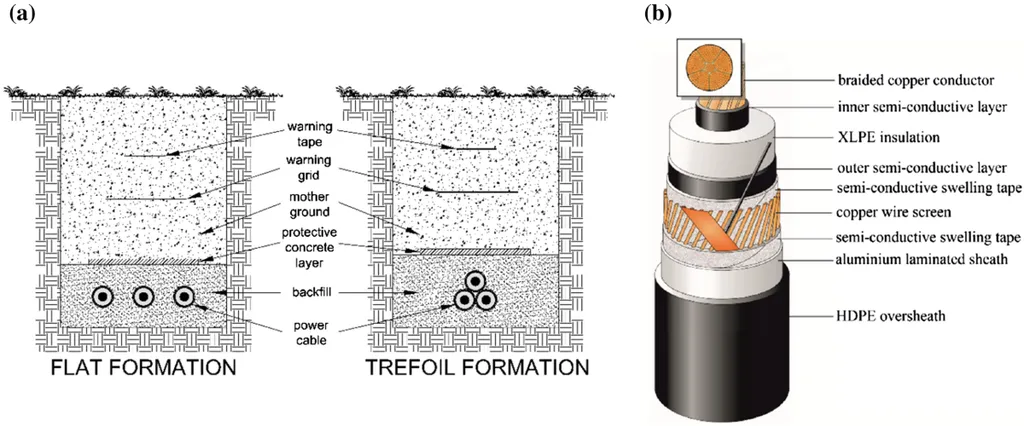

The problem is straightforward but significant. The thermal resistance of the soil surrounding power cables directly impacts their current-carrying capacity. When soil dries out or has high thermal resistance, cables can’t dissipate heat as effectively, reducing their capacity. This often leads to the need for larger, more expensive cables to handle the required load. “One of the ways to improve cooling conditions is to use a special backfill with lower thermal resistance values,” Vysotski explains. “However, these materials are more expensive than standard soil, raising questions about their cost-effectiveness.”

Vysotski’s research proposes an optimization technique that considers the reduced costs of cable, line construction, and operating expenses. The model accounts for both normal and post-emergency operating modes, providing a comprehensive view of the economic impacts. The key finding? In some cases, using special backfill can increase cable current capacity enough to reduce the cable cross-section by one step, effectively offsetting the cost of the more expensive material. “Increasing the cable current capacity due to special backfilling can reduce the cable cross-section by one step and, thus, compensate for the cost of more expensive material,” Vysotski notes. “Otherwise, the use of special backfills becomes impractical.”

To solve this optimization problem, Vysotski employed a genetic algorithm implemented in the MS Excel environment. The results of the calculations demonstrate that the proposed methodology and algorithm can be applied to various voltage levels and laying conditions, allowing designers to select the most effective parameters for cable line construction.

The implications for the energy sector are substantial. By providing a clear, data-driven approach to optimizing cable line design, Vysotski’s research could lead to more efficient and cost-effective power transmission systems. This is particularly relevant in regions with challenging soil conditions or where energy demand is high. As the world continues to invest in infrastructure, studies like this one will be crucial in shaping the future of power transmission, ensuring that every degree of efficiency is captured and every cost is justified.

In an industry where margins can be tight and efficiency is paramount, Vysotski’s work offers a compelling case for careful consideration of backfill materials. It’s a reminder that sometimes, the key to unlocking greater efficiency lies not in radical innovation, but in optimizing the details. As the energy sector continues to evolve, research like this will be instrumental in driving progress and ensuring that power transmission systems are as efficient and economical as possible.