In a significant stride towards advancing biomedical titanium alloys, researchers have developed a novel, cost-effective method to fabricate complex parts with superior corrosion resistance and excellent biocompatibility. The study, led by Xia Li from the Department of Materials Science and Engineering at City University of Hong Kong, alongside collaborators from Southern University of Science and Technology and Songshan Lake Materials Laboratory, introduces a promising alternative to traditional titanium alloys used in medical implants.

The research focuses on the Ti–24Nb–4Zr–8Sn (Ti2448) alloy, which exhibits a low Young’s Modulus, making it an ideal candidate for next-generation biomaterials. The key innovation lies in the use of a net-shape powder metallurgy method, combined with hot isostatic processing and water quenching (SHIPQ). This approach not only reduces production costs but also enhances the material’s properties.

“Our method eliminates most pores during hot isostatic processing, significantly improving the alloy’s corrosion resistance,” explains Li. The corrosion rate of the Ti2448 alloy treated with SHIPQ is more than 3.5 times lower than that of the widely used Ti–6Al–4V (Ti64) alloy. This substantial reduction is primarily due to the lack of galvanic corrosion in a single β phase, as there is no driving force (potential difference) for such corrosion to occur.

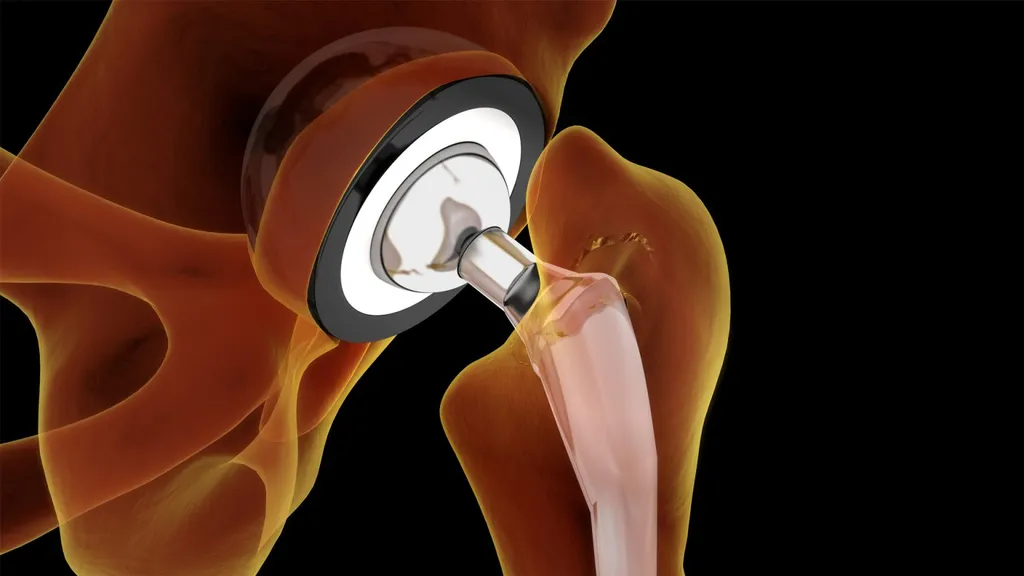

The study also highlights the excellent biocompatibility of the SHIPQ alloy. In cell culturing experiments with MG-63 cells, the alloy exhibited increased lamellipodia spread and pronounced filamentous filopodia, indicating better cell adhesion and proliferation. Additionally, micro-computed tomography (micro-CT) and Haematoxylin and eosin staining results of removed femoral implants showed a greater volume of new bone and higher mineral density around the implants, with no detectable inflammatory response.

The implications of this research are far-reaching, particularly for the biomedical industry. The development of a cost-effective, net-shape powder metallurgy method for fabricating complex parts of titanium alloys with superior properties opens new avenues for innovative medical implants. The low Young’s Modulus and lack of allergic or toxic elements in the SHIPQ alloy make it an excellent candidate for long-term implant applications, potentially revolutionizing the field of orthopedic surgery.

As the demand for advanced biomaterials continues to grow, this research provides a significant step forward in meeting the needs of the medical community. The study, published in the journal Materials Futures (translated as “Materials Future Prospects”), underscores the importance of interdisciplinary collaboration and innovative manufacturing techniques in driving progress in the field of biomaterials.

This breakthrough not only enhances our understanding of titanium alloys but also paves the way for future developments in medical technology. As the industry continues to evolve, the insights gained from this research will be instrumental in shaping the next generation of biomedical implants, ultimately improving patient outcomes and quality of life.