In the relentless pursuit of innovative solutions to environmental challenges, a team of researchers has developed a promising new material that could revolutionize oil spill cleanup and water treatment processes. Led by Letícia Matos Machavelli, a scientist affiliated with a prominent research institution, the study focuses on the creation of advanced membranes that could significantly enhance oil/water separation technologies.

The research, published in the journal ‘Materials Research’ (translated from Portuguese as ‘Pesquisa em Materiais’), introduces electrospun poly(vinyl chloride) (PVC)/silica membranes that feature in situ formation of modified silica nanodomains. This breakthrough was achieved by incorporating organosilane precursors during the electrospinning process, a method that involves using electric force to draw charged threads of polymer solutions into fibers.

“The key innovation here is the in situ sol-gel process that occurs during electrospinning,” explains Machavelli. “This allows us to create silica nanodomains within the PVC fibers, which enhances the material’s ability to adsorb oil from water.”

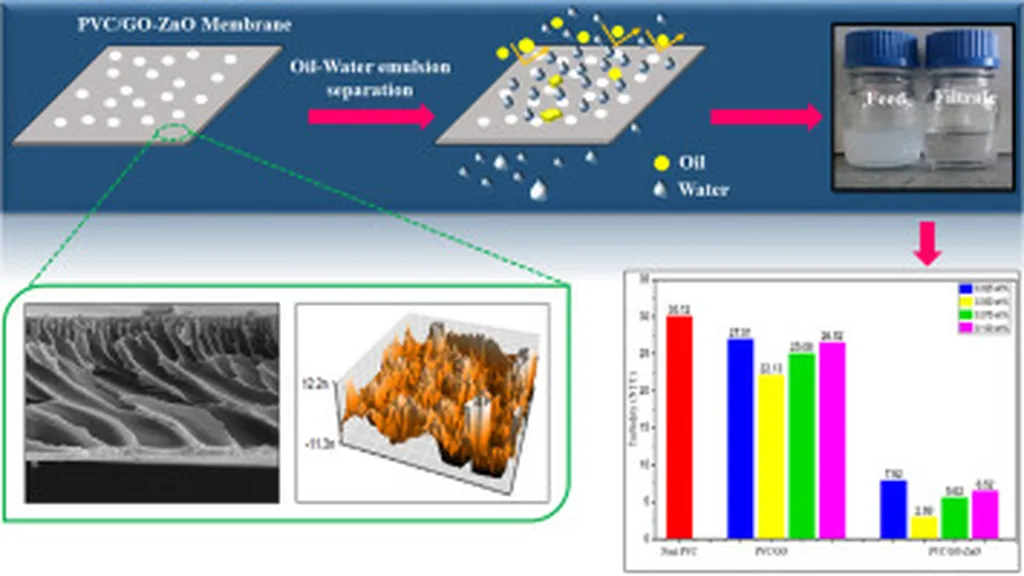

The membranes were fabricated using PVC solutions mixed with either (3-aminopropyl)triethoxysilane (APTS) or 3-(triethoxysilyl)propyl isocyanate (TEPI) as precursors. The resulting membranes were characterized using various techniques, including scanning and transmission electron microscopies, energy-dispersive X-ray spectroscopy, and differential scanning calorimetry. These analyses confirmed the successful formation of silica nanodomains, which play a crucial role in the material’s performance.

One of the most significant findings was the tunable hydrophobicity of the membranes. The contact angle of the PVC membranes decreased with the incorporation of silica nanodomains, indicating improved oil sorption performance. Notably, the sample prepared with 5 wt% APTS showed the highest performance, highlighting the potential of these membranes for oil/water separation applications.

The implications of this research are far-reaching, particularly for the energy sector. Efficient oil/water separation is critical for environmental protection and resource recovery, and the development of these advanced membranes could lead to more effective and sustainable solutions for managing oil spills and treating industrial wastewater.

“The potential applications of these membranes extend beyond oil spill cleanup,” says Machavelli. “They could also be used in various industrial processes where efficient separation of oil and water is required, such as in the petrochemical and food industries.”

As the world continues to grapple with environmental challenges, innovations like these offer hope for a cleaner and more sustainable future. The research conducted by Machavelli and her team represents a significant step forward in the development of advanced materials for environmental remediation, with the potential to shape future developments in the field.

With the growing demand for efficient and eco-friendly solutions, the commercial impact of this research could be substantial. The energy sector, in particular, stands to benefit from the enhanced capabilities of these membranes, paving the way for more effective and sustainable practices in oil and gas production, as well as in the management of industrial effluents.

In summary, the development of these nanostructured PVC/silica membranes marks a significant advancement in the field of oil/water separation. The research not only highlights the potential of electrospinning and sol-gel processes in creating advanced materials but also underscores the importance of interdisciplinary collaboration in addressing global environmental challenges. As the world continues to seek innovative solutions, the work of Machavelli and her team serves as a beacon of progress, inspiring further exploration and development in the realm of sustainable technologies.