In the quest for innovative construction materials that are both sustainable and high-performing, researchers have turned their attention to a unique blend of magnesium sulfate cement and cellulosic fibers. A recent study published in *Materials Research* (translated from Portuguese) sheds light on how incorporating eucalyptus fibers into basic magnesium sulfate cement (BMSC) can enhance its properties, potentially revolutionizing the construction industry.

Juan C. A. Molano, the lead author of the study, explains, “Our research aimed to understand how different dosages of bleached eucalyptus fibers affect the physical, mechanical, and microstructural properties of BMSC composites.” This exploration is crucial, as BMSC is already known for its fire resistance, lightweight properties, and low alkalinity, making it a popular choice for lightweight panels. However, the impact of cellulosic fibers on its hydration mechanisms and mechanical performance has remained largely unexplored until now.

The study reveals that the 5-1-7 phase, a key component in BMSC, enhances mechanical strength through a space-filling effect. However, the incorporation of fibers introduces a complex interplay of benefits and challenges. While higher fiber contents increase porosity and reduce compressive strength, they also improve flexural strength and energy absorption due to fiber-bridging effects. This balance is critical for applications in the construction sector, where both strength and toughness are paramount.

Molano highlights the significance of these findings: “By optimizing the fiber dosage, we can strike a balance between strength and toughness, making BMSC composites more versatile for various construction applications.” This optimization could lead to the development of materials that are not only stronger and more durable but also more sustainable, aligning with the growing demand for eco-friendly construction solutions.

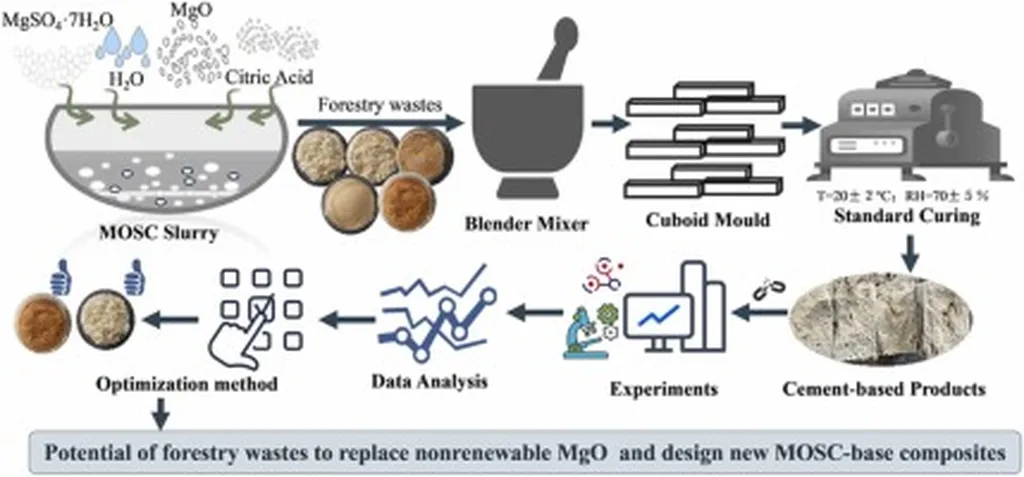

The research employed a range of analytical techniques, including mechanical tests, X-ray diffraction (XRD), Fourier-transform infrared spectroscopy (FTIR), thermogravimetric analysis (TGA), and Digital Image Correlation (DIC). These methods provided a comprehensive understanding of the hydration reactions and phase formation within the composites, offering valuable insights for future material design.

As the construction industry continues to seek innovative materials that can meet the demands of modern infrastructure, the findings from this study could pave the way for new developments. The potential to enhance the performance of BMSC through the strategic incorporation of cellulosic fibers opens up exciting possibilities for the energy sector, where lightweight, fire-resistant materials are in high demand.

In conclusion, this research not only advances our understanding of BMSC composites but also highlights the importance of interdisciplinary collaboration in driving innovation. As Molano and his team continue to explore the potential of these materials, the construction industry stands to benefit from stronger, more sustainable, and more versatile building solutions. The study, published in *Materials Research*, serves as a testament to the power of scientific inquiry in shaping the future of construction.