In a breakthrough that could reshape surface strengthening technologies, a team of researchers from the State Key Laboratory of Advanced Marine Materials and the Key Laboratory of Nuclear Materials and Safety Assessment has uncovered the intricate dance between rare earth content and the performance of chromium infiltration layers in 316H heat-resistant steel. The study, led by Liu Ji and published in *Teshugang* (which translates to *Heat Treatment*), delves into the effects of yttrium oxide (Y2O3) doping on the tribological and corrosion resistance properties of these layers, offering promising insights for the energy sector.

The research team employed the solid powder pack cementation method to investigate how varying concentrations of Y2O3 influence the formation and performance of chromium infiltration layers. Their findings revealed that rare earth doping significantly regulates the formation process of these layers. “When the w[Y2O3] was 4%, the thickness of the infiltration layer reached a maximum value of 143.78 μm, which was 10.2% higher than that of the undoped group,” explained Liu Ji. This enhancement in thickness is just the tip of the iceberg, as the study also uncovered substantial improvements in other critical properties.

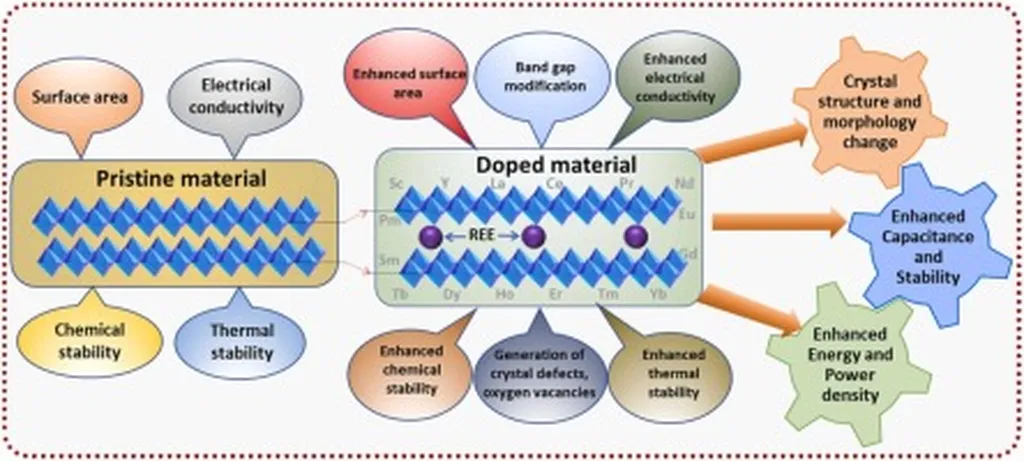

The optimal concentration of Y2O3 was found to be 2%, where the surface micro-Vickers hardness (HV) was enhanced to 656HV, the friction coefficient was reduced by 52.7% (to 0.355), and the wear rate was decreased by 74.5%. “The rare earth Y2O3 promoted the preferential growth of the Cr₂C phase, accelerating chromium diffusion, refining grains, and regulating phase composition,” said Liu Ji. However, the team also discovered that there is a concentration threshold for its effect. Excessive w[Y2O3] (>4%) not only consumed a large amount of catalyst, reducing the diffusion driving force of active chromium atoms but also increased the surface roughness and deteriorated the tribological properties.

The study also highlighted a negative impact on corrosion resistance due to the chromium-depleted phenomenon at the grain boundaries caused by Y2O3 addition. This nuanced understanding of the role of rare earth doping in chromium infiltration processes provides a theoretical basis for optimizing surface strengthening technologies, which is of great significance for developing high wear resistance and low friction materials.

The implications for the energy sector are substantial. The enhanced wear resistance and reduced friction coefficients could lead to more durable and efficient components in power generation and transmission systems. Moreover, the improved corrosion resistance, despite the noted challenges, offers a pathway to longer-lasting materials in harsh environments.

As the energy sector continues to demand more robust and efficient materials, this research paves the way for innovative surface treatments that can withstand extreme conditions. The findings not only advance our understanding of rare earth doping but also open new avenues for developing advanced materials tailored for the energy industry.