In a groundbreaking development that could revolutionize the energy sector, researchers have discovered a novel way to enhance the superelasticity of shape memory alloys, making them more versatile and durable for practical engineering applications. The study, led by Xinghao Li from the College of Materials Science and Chemical Engineering at Harbin Engineering University in China, introduces a strategy that could overcome long-standing limitations in polycrystalline functional materials.

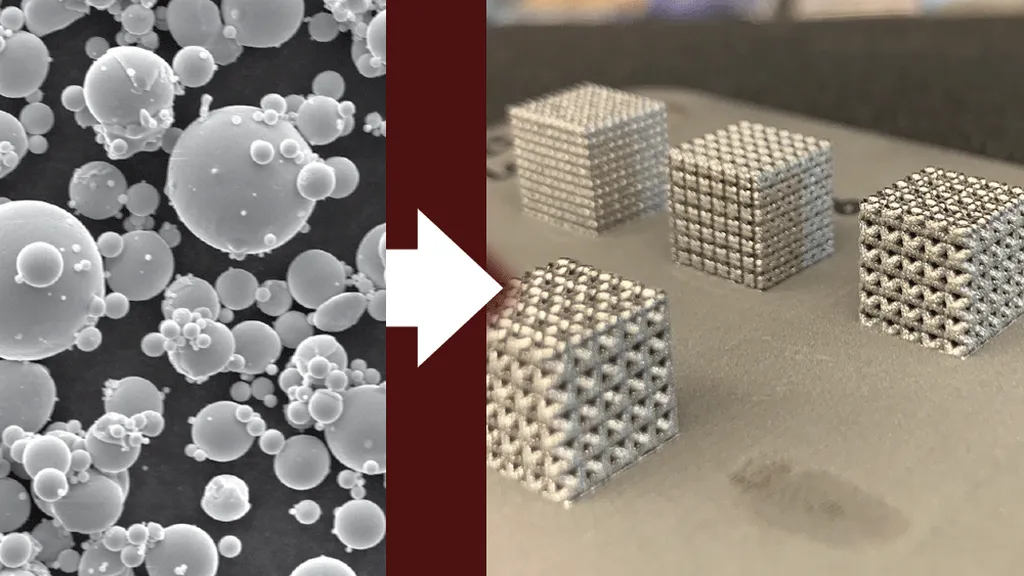

Shape memory alloys are renowned for their ability to return to their original shape after being deformed, a property known as superelasticity. However, achieving high superelasticity in these materials has been challenging due to strain incompatibilities arising from grain orientation. The research team tackled this issue by developing a heterogeneity-driven texture optimization strategy, specifically targeting CuAlMn alloys.

“By controlling the deformation process, we were able to imprint a heterogeneous dislocation density in differently oriented grains,” explained Li. “This created gradients of sub-boundary energy, which drove selective grain boundary migration. Essentially, we encouraged the growth of grains with favorable orientations for superelasticity.”

The result was a significant increase in the fraction of <015>-oriented grains, from around 19% to a remarkable 70%. This optimization led to an unprecedented tensile superelastic strain of approximately 8.0% in equiaxed CuAlMn alloys. The findings were recently published in the journal *Materials Futures*, which translates to “Materials Horizons” in English.

The implications of this research are substantial for the energy sector. Shape memory alloys are already used in various applications, including actuators, sensors, and energy absorption devices. The enhanced superelasticity achieved through this new strategy could lead to more efficient and reliable components in these systems. For instance, in the oil and gas industry, shape memory alloys are used in downhole tools and valves, where their ability to withstand extreme conditions and maintain functionality is crucial.

Moreover, the microstructural heterogeneity-guided strategy developed by Li and his team offers a general framework for overcoming texture-related limitations in other polycrystalline functional materials. This could pave the way for advancements in a wide range of industries, from aerospace to automotive, where materials with superior mechanical properties are in high demand.

As the energy sector continues to evolve, the need for innovative materials that can withstand harsh environments and perform reliably becomes increasingly important. The research conducted by Xinghao Li and his colleagues represents a significant step forward in this area, offering a promising solution to a long-standing challenge in materials science.

“This discovery not only advances our understanding of shape memory alloys but also opens up new possibilities for their application in the energy sector,” said Li. “We are excited about the potential impact of this research and look forward to seeing how it shapes future developments in the field.”