In the intricate world of underground construction, shield tunnels play a pivotal role, particularly in the energy sector, where they transport vital resources and house critical infrastructure. However, these tunnels are not immune to failures, and when they occur, the consequences can be catastrophic. A recent study published in the *Journal of Civil Engineering and Management* (translated from Lithuanian as *Civilinė Inžinerija ir Vadyba*) sheds new light on the progressive failure of segmental linings in shield tunnels, offering insights that could revolutionize the way we approach tunnel safety and design.

At the heart of this research is Tianqi Zhang, a researcher from the MOE Key Laboratory of Coast Civil Structure Safety at Tianjin University in China. Zhang and his team have tackled a longstanding challenge in the field: understanding the trigger mechanisms behind the progressive damage or failure of segmental linings in shield tunnels. “Many engineering accidents in shield tunnels occur because localized failure induces the progressive damage or failure of segmental linings,” Zhang explains. “However, knowledge of this trigger mechanism is still very limited.”

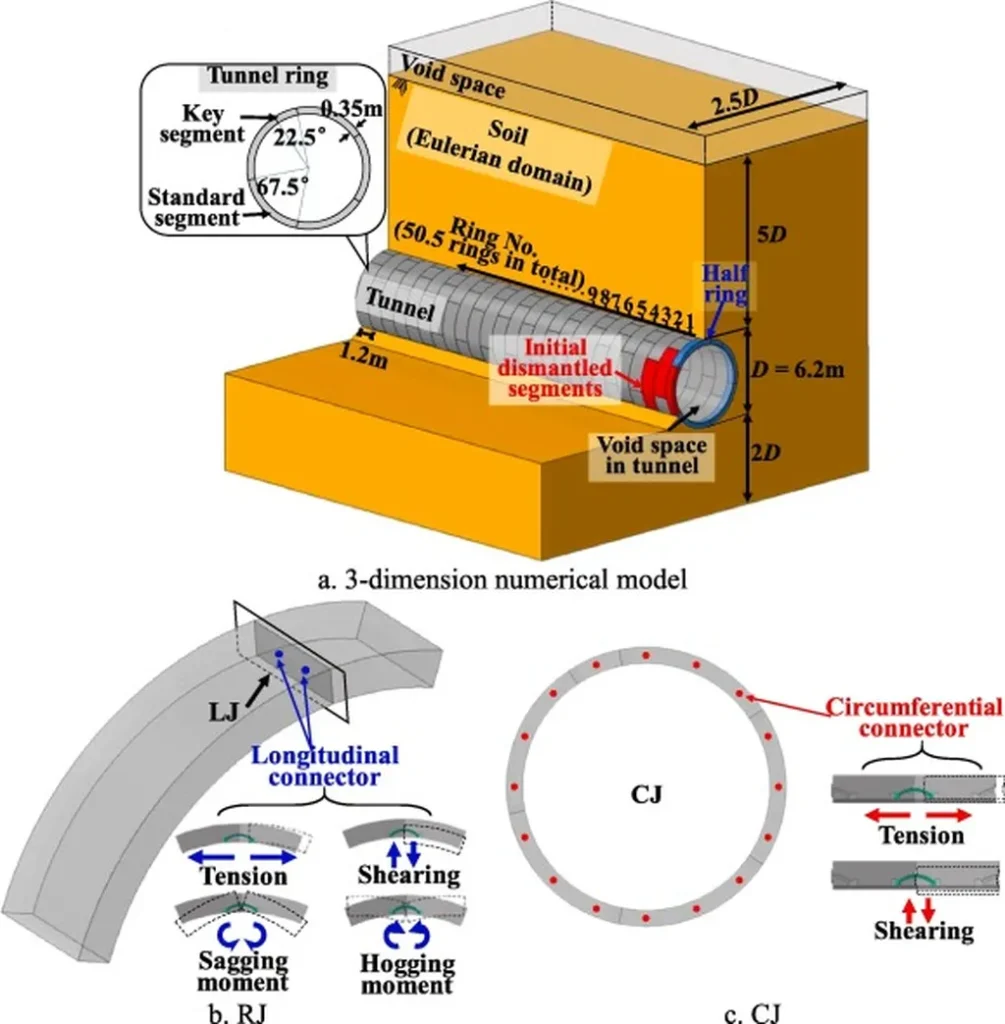

To bridge this knowledge gap, Zhang and his team turned to numerical simulations. They developed a sophisticated model of segmental linings based on the concrete damage plasticity (CDP) model and element deletion technology. This model was verified using data from current structural loading tests, ensuring its accuracy and reliability. “Before simulating tunnel failure, it is important to establish a sophisticated model that considers the damage behaviour of segmental linings,” Zhang notes.

The team then applied this model to simulate the progressive failure of segmental linings due to localized failure in a shield tunnel, considering complex soil-tunnel interactions. The results were enlightening. The numerical analysis showed that concrete was damaged in the segments adjacent to the localized failure zone. Some of the stirrups and erection bars in these segments yielded, while the upper and lower rows of steel bars as well as the bolts connecting the segments had sufficient safety redundancy.

So, what does this mean for the energy sector and the construction industry at large? The implications are significant. By understanding the progressive failure mechanisms of segmental linings, engineers can design more robust and safer shield tunnels. This could lead to reduced maintenance costs, improved safety for workers, and enhanced reliability for the energy infrastructure that relies on these tunnels.

Moreover, the research highlights the importance of considering soil-tunnel interactions in the design and analysis of shield tunnels. This could pave the way for more sophisticated and accurate modeling techniques, further improving the safety and efficiency of underground construction projects.

As we look to the future, the research conducted by Zhang and his team could shape the development of new design standards and guidelines for shield tunnels. It could also spur further research into the progressive failure mechanisms of other types of underground structures, ultimately leading to a safer and more reliable underground infrastructure network.

In the words of Zhang, “This research is just the beginning. There is still much to learn about the progressive failure of segmental linings in shield tunnels. But with each new discovery, we move one step closer to a safer and more efficient underground construction industry.”