In the quest for sustainable construction materials, researchers are increasingly turning to waste products to enhance performance and reduce environmental impact. A recent study published in the *Journal Innovation of Civil Engineering* (translated from Indonesian as *Journal of Civil Engineering Innovation*) explores the potential of coconut fiber and superplasticizer liquid to bolster the compressive strength of paving blocks. Led by Fairus Zabadi of Universitas Madura, this research could pave the way for more eco-friendly and durable construction materials, with significant implications for the energy sector and beyond.

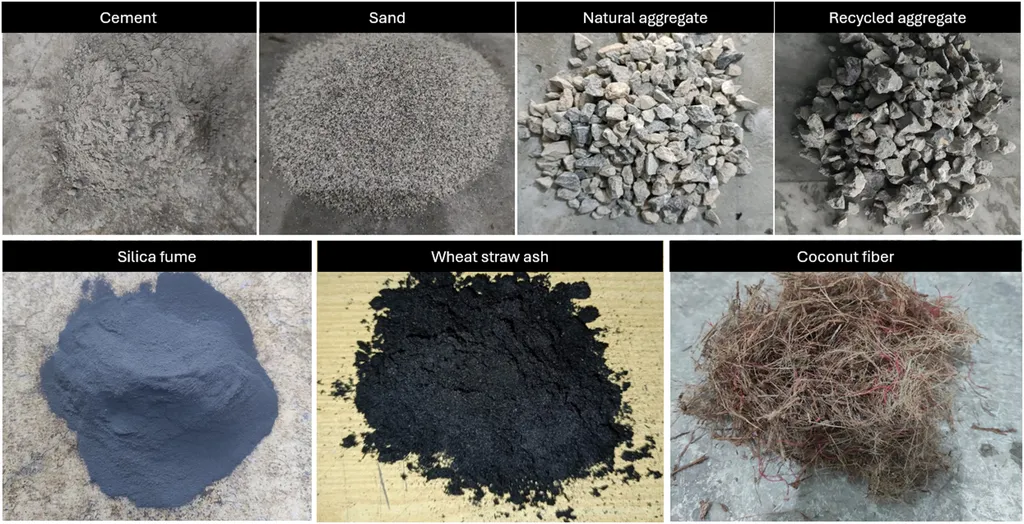

Paving blocks are a staple in urban infrastructure, but their environmental footprint is often overlooked. Zabadi’s study investigates how adding coconut fiber—a typically discarded agricultural byproduct—and superplasticizer liquid can improve the strength and sustainability of these blocks. The findings are promising: paving blocks mixed with these additives demonstrated higher compressive strength compared to traditional blocks, suggesting that waste materials can indeed be repurposed to enhance construction performance.

“By incorporating coconut fiber and superplasticizer liquid, we not only reduce environmental pollution but also create a stronger, more resilient building material,” Zabadi explains. “This research highlights the untapped potential of waste materials in construction, offering a sustainable solution that doesn’t compromise on quality.”

The study tested two mixtures: a 1:5 ratio and a 1:6 ratio of cement to aggregate, each with varying amounts of coconut fiber and superplasticizer. The results were striking. The 1:5 mixture with additives achieved an average compressive strength of 305.42 kg/cm², while the 1:6 mixture reached 237.45 kg/cm². In comparison, traditional 1:5 and 1:6 paving blocks registered strengths of 203.47 kg/cm² and 184.59 kg/cm², respectively. These findings suggest that the addition of coconut fiber and superplasticizer significantly enhances the load-bearing capacity of paving blocks, making them more durable and long-lasting.

The commercial implications of this research are far-reaching. For the energy sector, which often relies on robust infrastructure to support power plants, pipelines, and renewable energy installations, stronger and more sustainable paving materials could reduce maintenance costs and environmental impact. As industries increasingly prioritize sustainability, the adoption of such innovative materials could become a competitive advantage, aligning with global efforts to reduce waste and carbon footprints.

Beyond the energy sector, Zabadi’s research could influence urban planning and construction practices worldwide. By demonstrating that waste materials can be transformed into high-performance building components, the study challenges conventional notions of what constitutes a viable construction material. This shift could lead to broader adoption of circular economy principles in the construction industry, where waste is minimized, and resources are maximized.

As the world grapples with the challenges of climate change and resource depletion, research like Zabadi’s offers a glimmer of hope. By turning waste into opportunity, we can build a more sustainable future—one paving block at a time.